Semiconductor

According to the data of The World Semiconductor Trade Statistics (WSTS) in August 2021, the size of the global semiconductor market is gradually expanding with the growth of the global economy and is expected to reach 606.5 billion US dollars in 2022, higher than the 204.4 billion US dollars in 2000. However, there are obvious differences in the development of semiconductor industry regions, and the Asia-Pacific region has become an important settlement for the development of the global semiconductor industry.

The global semiconductor industry chain has formed a pattern of in-depth division of cooperation. The semiconductor companies in relevant countries have a high degree of specialization, forming complementary advantages in the design and production of semiconductor products. The regions with advantages in semiconductor development are the United States, Japan, Taiwan and China. The United States has obvious advantages in logic chip design and manufacturing equipment, while Japan has outstanding R&D strength in semiconductor materials in the Asia-Pacific region, and Taiwan has a leading position in wafer manufacturing and packaging test.

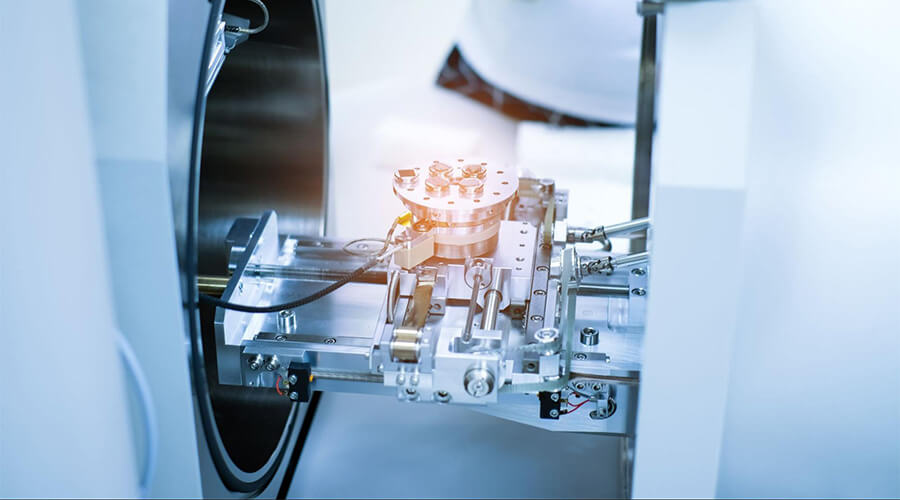

Semiconductor equipment is an important foundation of the semiconductor manufacturing industry. Semiconductor equipment is mainly divided into two categories: manufacturing equipment and packaging test equipment. Manufacturing equipment is mainly used in wafer manufacturing, including annealing furnaces, mask aligners, etching machines, ion implanters, film deposition equipment, etc. Packaging test equipment is mainly used in wafer packaging and testing, including dicing machines, breaking machines, wire bonders, testing machines, probe stations, sorting machines, etc.

WKPT provides parts manufacturing and reforming in semiconductor production equipment. We have excellent engineering technicians and production management team to optimize products and make improvements, through participatory design into the customer's manufacturing equipment parts process discussion and evaluation. In response to the differences in different manufacturing processes of semiconductor equipment, we can provide a small number of parts with special specifications, and perform reverse analysis according to the sample, so as to retrospectively obtain the processing flow, structural data and specifications of product remanufacturing. In response to the differences in manufacturing processes and equipment, we can provide part manufacturing with a small number of special specifications, and perform reverse analysis according to the sample, to retrospectively obtain the processing flow, structural data and specifications of product reforming.

With years of experience in metal processing solutions, WKPT offers relevant applications to middle and downstream customers in the semiconductor industry, mainly used in peripheral parts, such as valves, pumps, handling equipment and inspection equipment of the semiconductor industry. Our great deal of product processing and surface treatment experience, plus the know-how of metal forming and collaborative design, we can offer various manufacturing suggestions, complete production and competitive products for customers.