ESG Commitment - Sustainable Manufacturing & Corporate Responsibility

World Known Precision exports 85% of its products, with 43% destined for European and American markets. As the EU and US tighten their carbon emission regulations and implement carbon tax policies, World Known Precision,s automotive and wind power components must comply with low-carbon requirements and provide comprehensive carbon emission data. To meet market demands, World Known Precision has proactively launched environmental improvement initiatives, including replacing traditional air compressors with energy-efficient variable-frequency models.

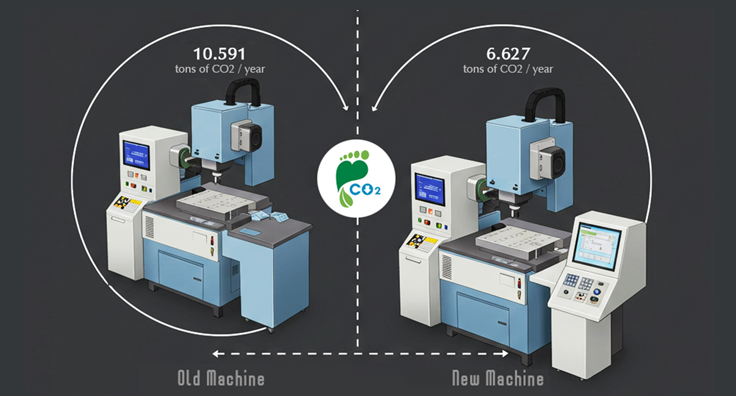

The company,s legacy processing equipment, which previously generated approximately 10.591 metric tons of CO2 emissions annually and consumed 21,396 kWh of electricity, has been replaced with advanced precision machinery. This upgrade has reduced carbon emissions to 6.627 metric tons of CO2, with projected annual savings of 8,337 kWh in electricity consumption and a decrease of 3.964 metric tons in carbon emissions. Beyond lowering the carbon footprint, this modernization has substantially improved the energy efficiency of the processing equipment, highlighting the significant impact of smart manufacturing solutions in environmental sustainability.

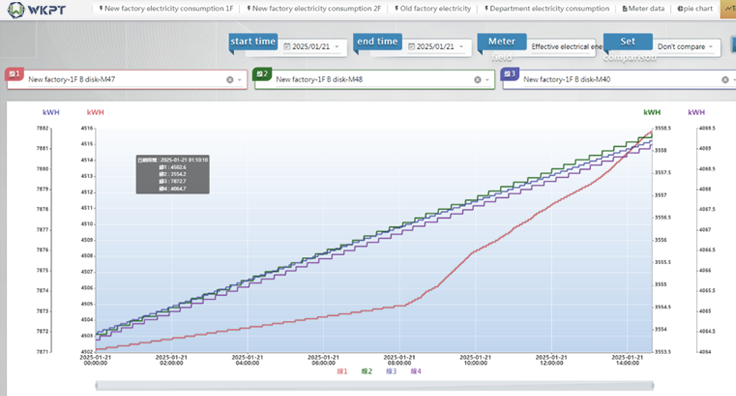

To enhance the precision and efficiency of carbon emission management, World Known Precision has deployed a smart metering system and established a comprehensive power consumption monitoring and analytics platform. This system tracks and analyzes real-time power consumption data from 48 machines and facilities, providing detailed carbon emission metrics that enable management to optimize energy usage and emission control. Furthermore, through an integrated dynamic carbon emission alert system, the platform immediately flags any emissions exceeding predetermined thresholds, allowing for real-time production adjustments to prevent energy waste and excessive emissions.

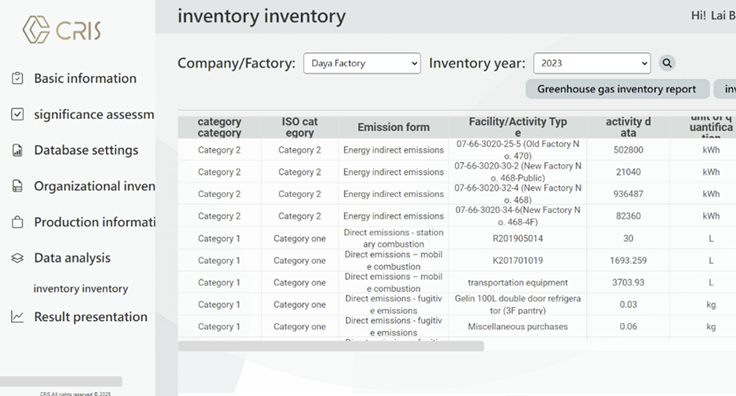

World Known Precision has implemented a Carbon Footprint Verification (CFV) system integrated with its smart metering infrastructure, enabling comprehensive carbon emission monitoring throughout the production process to finished products. The system performs detailed carbon footprint analyses for each product while providing data-driven recommendations for carbon reduction, supporting World Known Precision,s transition toward low-carbon operations.

World Known Precision,s sustainability initiatives have delivered substantial economic benefits while making positive environmental and social impacts. By reducing carbon emissions and energy consumption, the company has achieved lower operational costs and enhanced product competitiveness, particularly crucial in international markets with growing demand for sustainable products. Moreover, the modernization of equipment and expanded production capacity has generated new employment opportunities, contributing to regional economic growth.

World Known Precision remains committed to advancing low-carbon and smart manufacturing technologies while integrating ESG principles across its operations. Moving forward, the company will continue to modernize equipment, streamline production processes, and develop eco-friendly, low-carbon products. This strategy aims to strengthen its global market leadership while intensifying efforts to combat climate change and reduce global carbon emissions. Through sustained innovation and strategic investments, World Known Precision is building a robust foundation for long-term growth and advancing toward a sustainable future in collaboration with global partners.

The company prevents disasters through occupational safety and health control measures and performs emergency response-related operations, including entrusting professional manufacturers and technicians to regularly maintain and service firefighting equipment and appliances, holding at least one fire drill each year, regularly updating internal firefighting teams, and monthly supervision and management of fire and electricity use.

Employees are the company's greatest asset, so the company is also committed to the health care of its colleagues, including regular health checks for employees, the establishment of breastfeeding rooms, the installation of AEDs, and first aid training. In order to provide the best possible care for employees, we encourage them to fully express their opinions through various channels, including employee opinion mailboxes, monthly mobilization meetings, and "I want to say something".

Information and documents regarding the business dealings between our company and its customers are considered confidential and should be protected. Each colleague has the responsibility to protect and keep confidential the information and documents within his or her business scope. We have the responsibility not to disseminate information and documents related to known business; we have the responsibility not to inquire about information and documents that are not within our business scope, and we should have self-awareness and strictly enforce the principle of not leaking or disseminating the confidential information of the above companies or clients, so as to provide clients with a complete information confidentiality environment and win their trust.

-

We are committed to complying with environmental and occupational health and safety regulations, protecting the environment and preventing hazards, and continuously improving to achieve an energy-saving and harmless workplace.

-

Social care and community engagement represent fundamental values driving WKPT's commitment to sustainable development and responsible corporate citizenship since our founding in 1969 during Taiwan's transition from agricultural to light industry. Witnessing five decades of environmental transformation around our facilities—from forests, farms, and wheat fields to manufacturing plants, residences, and transportation infrastructure—WKPT embraces the philosophy of "taken from society, give back to society" through meaningful community connections and natural resource conservation. Our comprehensive social care initiatives include annual adoption programs supporting 10 children at Hueiming Blind School (a nearby Christian special education institution for visually-impaired students), regular donations of necessities and educational resources, and hosting performances at company events to maintain community bonds. Additionally, WKPT collaborates with ASPEC Sports Technology to support junior baseball development in eastern Taiwan through comprehensive sports science programs combining training, medical care, and nutrition services, while providing ongoing assistance to vulnerable children, public interest groups, "Dreams Come True" programs in remote areas, and local community development associations.

-

Adhering to the core values of "safety", "quality", "integrity", "cooperation" and "responsibility", we cultivate skills and enhance happiness internally; and establish a relationship of coexistence, prosperity and mutual growth with the society externally.