Precision lightweight aluminum alloy parts

Aluminum metal is a green material with lightweight, high strength, good ductility, and workability. Aluminum alloy will form a protective oxide film on its surface in the atmosphere and clean water, which can block the contact between the material and the corrosive element, with good corrosion resistance. Aluminum alloy is a metal structural material widely used in industry and has been used for many years in aerospace, transportation, machinery manufacturing, watercraft, and chemical industries. Aluminum alloys are also used in the manufacturing of semiconductor equipment, such as vacuum chambers, wafer carrier trays, and conveyor belt modules.

Aluminum alloy materials are also used in the electric vehicle industry, such as body, sheet metal, and components, because electric vehicles need to improve endurance by being lightweight. American electric vehicle manufacturer Tesla continues to research aluminum alloy materials and process technology for significant lightweight. By doing so, the battery energy consumption and driving noise will also be reduced because of its lightweight.

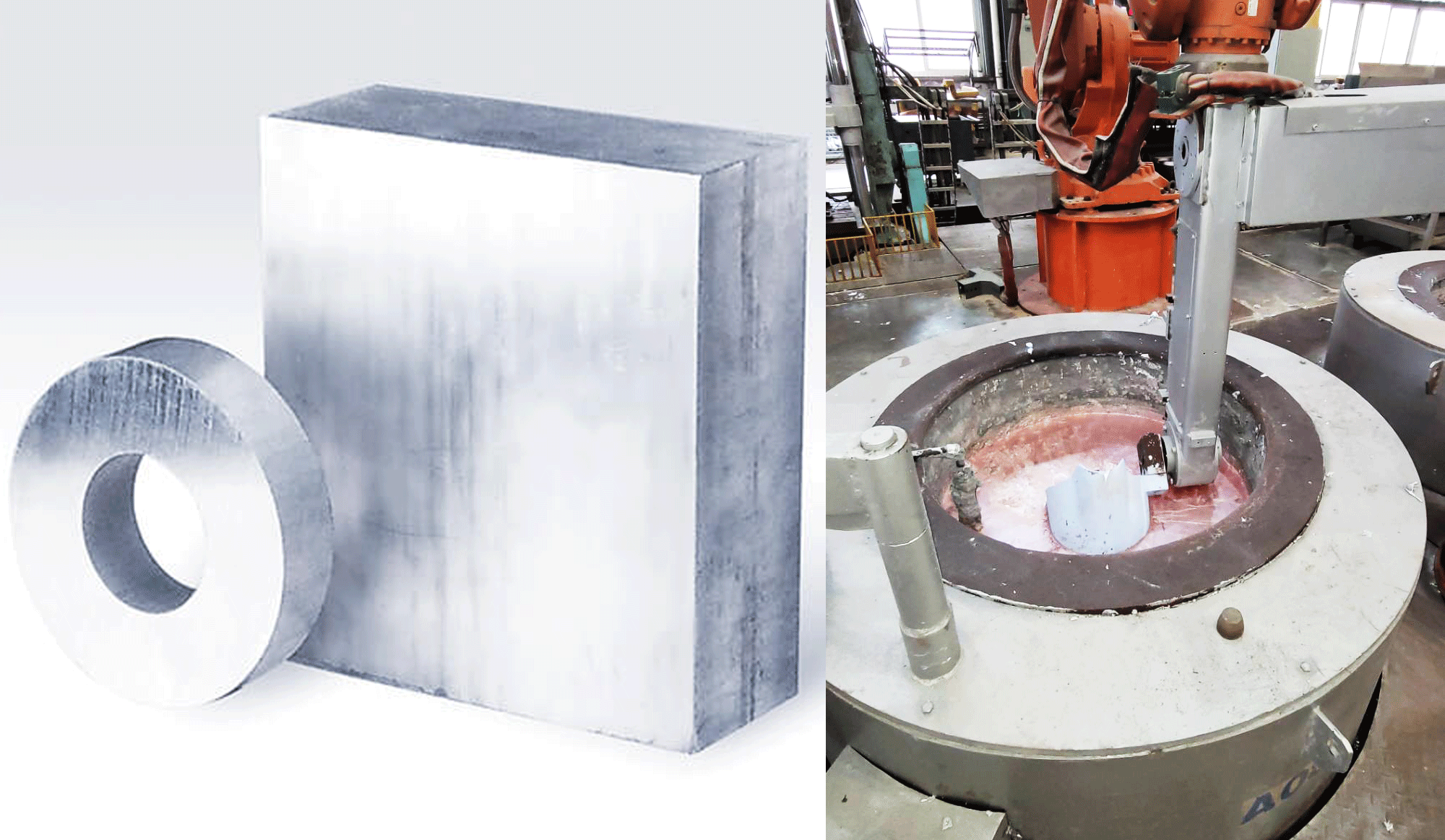

WKPT obtains different grades of aluminum alloy materials through the upstream supply chain and performs the machining of parts after aluminum rolling. By using three-axis CNC milling machines, machining centers, CNC and grinders, etc. to make high-precision mold parts. We also integrate the downstream supply chain to provide surface treatment to prevent corrosion of aluminum products, hard wear-resistant layers, insulating layers, spray-painted bottom layers, electroplated bottom layers, and other surface treatment-related processes.

- Wrought Aluminum Alloy:

It is an aluminum alloy whose structure and shape are changed through stamping, bending, rolling, extrusion, and other processes. It is melted and made into ingots, and then with metal plastic deformation processing to make various forms of aluminum alloys. - Cast aluminum alloy:

It is an aluminum alloy that fills the mold with molten metal to obtain blanks of various shapes. It has the advantages of low density, high strength, good corrosion resistance, and good DFM, and is less restricted by the structural design of parts.

| Category | ASTM Spec | JIS Spec | Chemical Composition (%) | Main Purpose | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Me | Mg | Zn | Ti | Cr | Ni | V | Other | AL | |||||

| General Manufacturing Quality | Major Mechanical Properties | Properties | Melting Range | Proportion | Conductivity | |||||||||||

| Quality | Tensile | Yield | Elongation | Machinability | Weldability | Corrosion Resistance | Surface Treatment | |||||||||

| 2000 Series Al-Cu Alloy |

2011 | A2011 | 0.4 | 0.7 | 5~6 | - | - | 0.3 | - | - | - | - | - | 0.05 | Margin | Optical supplies, fuzes, machinable materials |

| H112.H | T8 | 38 | 28 | 10 | △ | × | △ | △ | 535-643 | 2.82 | 45 | |||||

| 2014 | A2014 | 0.5-1.2 | 0.7 | 3.9-5 | 0.4-1.2 | 0.2-0.8 | 0.25 | 0.15 | 0.1 | - | - | - | 0.05 | Margin | Bicycle handlebars, seat posts, mechanical parts materials | |

| H112.H | T6 | 48 | 41 | 6 | ○ | △ | △ | △ | 507-638 | 2.8 | 40 | |||||

| 2017 | A2017 | 0.2-0.8 | 0.7 | 3.5-4.5 | 0.4-1 | 0.4-0.8 | 0.25 | 0.15 | 0.1 | - | - | - | 0.05 | Margin | Fuzes, Aviation Parts, Forgings | |

| O.T4-T451 | T4 | 35 | 22 | 12 | ○ | △ | △ | △ | 513-641 | 2.79 | 34 | |||||

| 2024 | A2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.25 | 0.15 | 0.1 | - | - | - | 0.05 | Margin | Mechanical parts, machinable materials | |

| O.T4-T451 | T4 | 49 | 35 | 10 | ○ | △ | △ | △ | 502-638 | 2.77 | 30 | |||||

| 5000 Series Al-Mg Alloy |

5052 | A5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.1 | - | 0.15-0.35 | - | - | - | 0.05 | Margin | Optical supplies, vehicles |

| O.112.H | H34 | 24 | 18 | 10 | △ | ◎ | ◎ | ◎ | 593-649 | 2.68 | 35 | |||||

| 5056 | A5056 | 0.3 | 0.4 | 0.1 | 0.05-0.2 | 4.5-5.6 | 0.1 | - | 0.05-0.2 | - | - | - | 0.05 | Margin | Optical supplies | |

| O.H112.H | H34 | 28 | 22 | 14 | △ | ◎ | ◎ | ◎ | 568-638 | 2.64 | 27 | |||||

| 5083 | A5083 | 0.4 | 0.4 | 0.1 | 0.4-1 | 4-4.9 | 0.25 | 0.15 | 0.05-0.25 | - | - | - | 0.05 | Margin | Ships, materials for construction | |

| O.H112.H | H112 | 29 | 13 | 12 | △ | ◎ | ◎ | ◎ | 579-641 | 2.66 | 29 | |||||

| 6000 Series Al-Mg-Si Alloy |

6061 | A6061 | 0.4-0.8 | 0.7 | 0.2 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | 0.04-0.35 | - | - | - | 0.05 | Margin | Materials for construction, bicycle parts |

| O.T4.T6.T651.T8 | T6 | 27 | 25 | 10 | △ | ◎ | ○ | ◎ | 582-652 | 2.7 | 43 | |||||

| 6063 | A6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | - | - | - | 0.05 | Margin | Building materials, heat-dissipating materials, heat exchangers | |

| T1.T5.T6.T8 | T5 | 16 | 11 | 8 | △ | ◎ | ◎ | ◎ | 616-654 | 2.7 | 55 | |||||

| 6013 | - | 0.6-1 | 0.5 | 0.6-1.1 | 0.2-0.8 | 0.8-1.2 | 0.25 | 0.1 | - | - | - | - | 0.05 | Margin | Materials for bicycles | |

| O.T4.T6 | T6 | 30 | 26 | 10 | 0.2 | ◎ | ◎ | ◎ | - | 2.76 | - | |||||

| 6011 | A6011 | 0.6-2 | 1 | 0.4-0.9 | 0.8 | 0.6-1.2 | 12 | 0.2 | 0.3 | 0.2 | - | - | 0.05 | - | Defense, Sports Equipment, Transportation, Textile | |

| O.T4.T6 | T6 | 38 | 34.5 | 12 | ◎ | ○ | ○ | ○ | 565-650 | 2.7 | 36 | |||||

| 6066 | A6066 | 0.9-1.8 | 0.5 | 0.7-1.2 | 0.6-1.1 | 0.8-1.4 | 0.25 | 0.2 | 0.4 | - | - | - | - | - | ||

| O.T4.T6.T651 | T6 | 49 | 36.5 | 12 | ◎ | ○ | ○ | ○ | 565-650 | 2.7 | 37 | |||||

| 7000 Series Al-Zn-Mg Alloy |

7001 | - | 0.35 | 0.4 | 1.6-2.6 | 0.2 | 2.6-3.4 | 6.8-8 | 0.01-0.06 | 0.18-0.35 | - | - | - | 0.05 | Margin | Sports Equipment |

| O.T651.6511 | T651 | 57 | 50 | 10 | ○ | △ | △ | △ | - | 2.82 | ||||||

| 7005 | - | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1-1.8 | 4~5 | 0.01-0.06 | 0.06-0.2 | - | - | Zr0.08-0.2 | 0.05 | Margin | Bicycle materials, welding construction materials | |

| O.T1.T5.T6 | T53 | 36 | 31 | 10 | ○ | ◎ | ○ | △ | 615-643 | 2.78 | 41 | |||||

| 7046 | - | 0.12 | 0.15 | 2-2.6 | 0.1 | 1.9-2.6 | 5.7-6.7 | 0.06 | 0.04 | - | - | Zr0.08-0.15 | 0.05 | Margin | Aviation materials, sports equipment | |

| O.T651.6511 | T651 | 41.7 | 36.5 | 10 | ○ | △ | △ | △ | 488-629 | 2.83 | 41 | |||||

| 7050 | - | 0.12 | 0.15 | 2-2.6 | 0.1 | 1.9-2.6 | 5.7-6.7 | 0.06 | 0.04 | - | - | Zr0.08-0.15 | 0.05 | Margin | ||

| O.T651.6511 | T651 | 57 | 50 | 7 | ○ | △ | △ | △ | 488-629 | 2.83 | 41 | |||||

| 7075 | A7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 5.1-6.1 | - | 0.18-0.28 | - | - | - | 0.05 | Margin | Aviation materials, defense weapons, sports equipment | |

| O.T6.T6511 | T6 | 57 | 50 | 7 | ○ | △ | △ | △ | 476-638 | 2.8 | 33 | |||||

| 7178 | A7178 | 0.4 | 0.5 | 1.6-2.4 | 0.3 | 2.4-3.1 | 6.3-7.30 | 0.20Zr0.10 | 0.18-0.35 | - | - | - | - | - | Aviation materials, sports equipment | |

| O.T6.T76.T7651 | T6 | 62 | 55 | 10 | ○ | △ | △ | △ | - | - | - | |||||

| - | A7N01 | 0.3 | 0.35 | 0.2 | 0.2-0.7 | 1~2 | 4~5 | 0.2 | 0.3 | - | 0.1 | Zr0.25 | 0.05 | Margin | Bicycle materials, welding construction materials | |

| O.T1.T5.T6 | T5 | 32 | 27 | 10 | ○ | ◎ | ○ | △ | 615-413 | 2.78 | 41 | |||||

◎ Excellent ○ Good △ Not Good × Not Suitable Bi: 0.2-0.6 Pb: 0.2-0.4

- 2011:

Free-cutting alloys with good machinability and high strength, but have poor corrosion resistance. - 2014, 2017, 2024:

It contains a large amount of Cu. It has poor corrosion resistance, but has high strength and can be used as a structural material. Forgings are also applicable. Used in aircraft, gears, hydraulic components, and axles.

- 5052:

It is the most representative alloy with medium strength, good corrosion resistance, weldability, and formability, especially high fatigue strength, and good seawater resistance. Commonly used in general sheet metal, ships, vehicles, buildings, bottle caps, and honeycomb panels. - 5056:

Good corrosion resistance. Surface modified by cutting. Easy for anodic oxidation treatment and dyeability. Used in camera body, communication device unit, and zipper. - 5083:

Alloys for welding structures. It is a corrosion-resistant alloy with the highest strength among practical non-heat-treated alloys and is suitable for welding structures. Seawater resistance and good low-temperature properties. Used in ships, vehicles, low-temperature vessels, and pressure vessels.

- 6061:

Heat-treated corrosion-resistant alloy. It will be very high endurance with T6, but the strength of the welded joint is low. Used for screws, anchors, ships, vehicles, and land structures. - 6063:

A representative alloy for extrusion. The strength is lower than that of 6061, the extrudability is good, and it can be used as a shape material with complex cross-sectional shapes. It has good corrosion resistance and surface treatment. Commonly used in construction, highway guardrails, high fences, vehicles, furniture, home appliances, and decorations.

- 7075:

One of the alloys with the highest strength among the aluminum alloys, but the corrosion resistance is not good. The covering with 7072 can improve its corrosion resistance, but the cost increases. Suitable for thick plate and forged aircraft.

| Aluminum Alloy For Casting | |||

|---|---|---|---|

| JAPAN | GERMANY | UNITED KINGDOM | UNITED STATES |

| JIS | DIN | BS | AA |

| AC4C | LM25 | 356 | |

| AC3A | G-AlSil2 | LM6 | 413.2 |

| ADC1 | GD-A1SH2 | LM6 | 413 |

| ADC3 | GD-AlSilOMg | LM20 | 360 |

| ADC5 | GD-AlMg8Cu | 518.2 | |

| ADC6 | GD-AlMg3Cu | LM5 | 514 |

| ADC10 | GD-AlSi8Cu3Fe | LM24 | 380.1 |

| ADC12 | LM12 | 383 | |