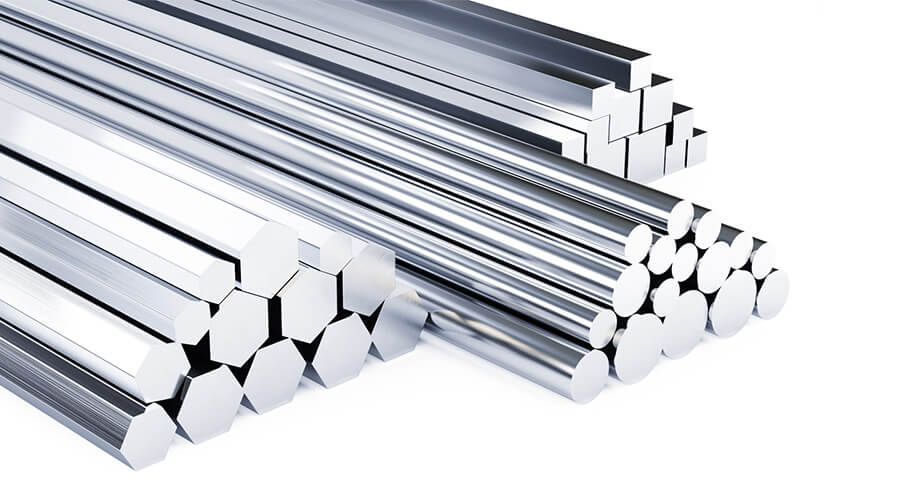

Corrosion-resistant stainless steel parts

The industrial application of stainless steel is widely used in manufacturing, construction, consumer industry, and national defense.

In recent years, the global trend towards material properties is longevity, energy-efficient and eco-friendly. Stainless steel has received more attention for its heat resistance, high-temperature corrosion resistance, and extension of transportation facilities such as bridges and tracks. Stainless steel has the properties of high strength, elasticity, non-magnetic, and non-leaching, which is widely used in semiconductor manufacturing and equipment components.

WKPT uses stainless steel materials to manufacture components applied in semiconductor, optoelectronics, biochemical technology, and other industries, such as high cleanliness equipment parts required in producing various PCBs, or high corrosion resistance valve parts required for special chemical pipelines in biochemical technology. Our precision machining process can achieve high-precision, high-performance quality requirements.

| Types | Alternative Name | magnetic | Properties | Elements |

|---|---|---|---|---|

| 304 | 18/8 food grade stainless steel |

No | Strong corrosion resistance, lower hardness than 430, 440 | 18% chromium, 8% nickel, 2% manganese. Contains a high proportion of nickel, with better corrosion resistance; non-magnetic. When the impurity content is high, it will occasionally become weak magnetic after processing. Good workability |

| 316 | 18/10 Medical Grade Stainless Steel |

No | Corrosion resistance is stronger than 304, salt resistance; hardness is lower than 430, 440 | 18% chromium, 10% nickel, 2% manganese, 5% molybdenum. The high content of nickel has better corrosion resistance. With molybdenum element has more corrosion resistance and chloride corrosion resistance, more strength as well. |

| 430 | Yes | Medium corrosion resistance. The oxidation layer on the surface layer is obvious, and it will fall off when hard brushing. | 18% chromium, 0% nickel, 1% manganese. Low price, no nickel. Poor corrosion resistance and easy to rust after long-term use. |

Stainless steel is composed of iron, carbon, chromium, and other alloy elements.