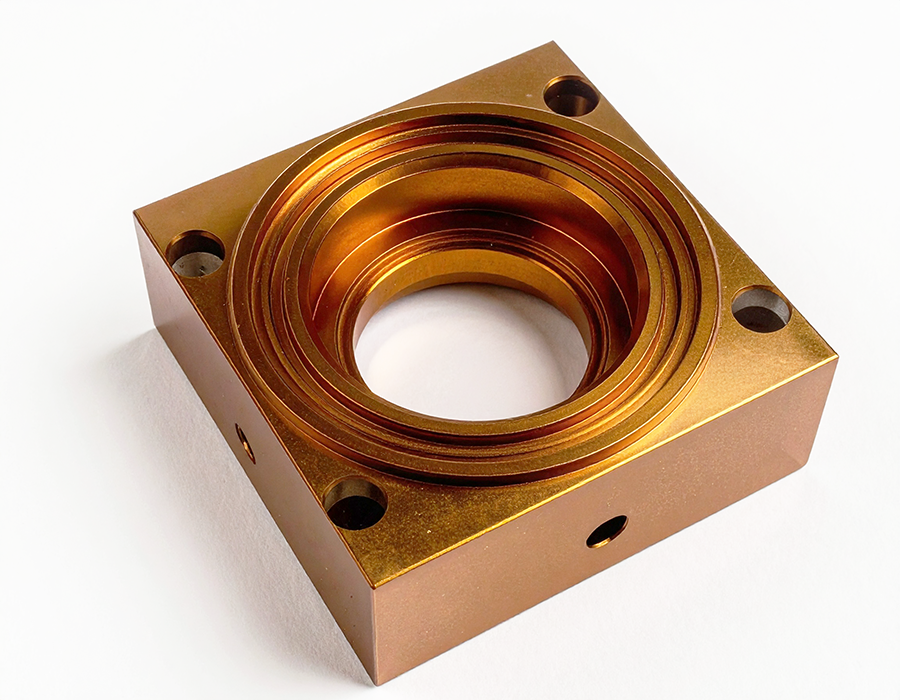

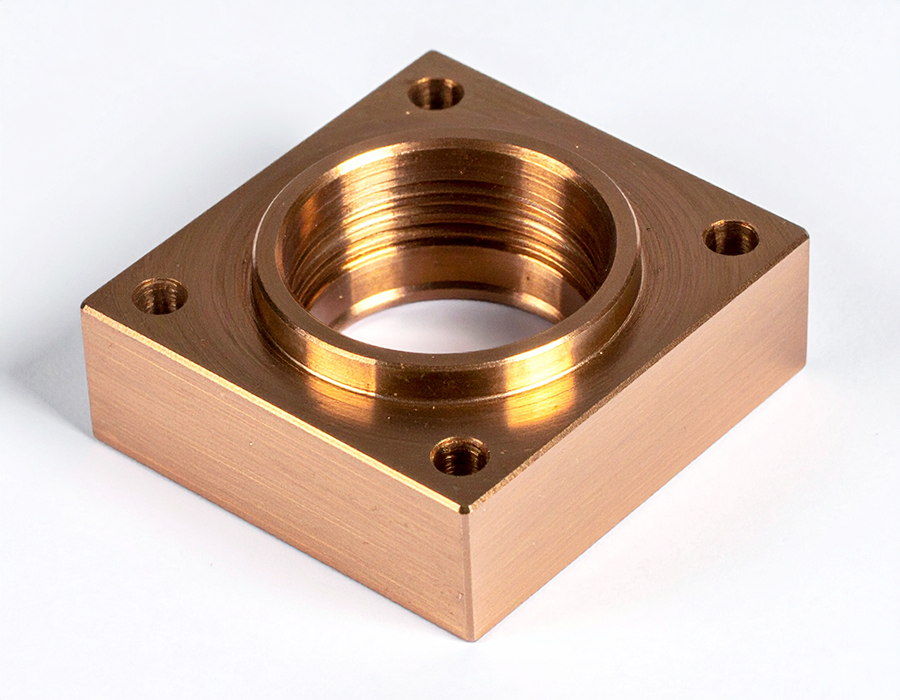

Precision Sensor Machining | Pressure Detection Component Manufacturing

Precision sensors are manufactured from premium copper alloy, specifically engineered for precision testing equipment environments.

The copper alloy material provides exceptional elasticity and electrical conductivity, ensuring precise operation of pressure sensing systems.

The sensor is installed in the core measurement area of the testing system, spanning between the reference chamber and the test chamber. Its functions include continuous pressure change detection, precise leak condition determination, electrical signal conversion, and high-resolution measurement capabilities. The working principle utilizes high-precision capacitive pressure sensing technology, where pressure changes cause minute deformation in the sensing diaphragm, resulting in capacitance value changes that are converted into precise electrical signals.

Product Applications

Precision Testing Equipment, Industrial Test Equipment

Gas leak testing, Automated leak testing, Helium leak testing, Hydrogen leak testing, Leak detection, Leak detectors, Pressure leak testing, Medical device leak testing, Package leak testing, Pressure leak testing, Vacuum leak testing, Valve leak testing

Workpiece Material

Copper Alloy

Manufacturing Processes

Turning, Milling, Drilling, Tapping

View More...

Quality Inspection

Beyond Copper Alloy: Your One-Stop Precision Testing Equipment Parts Supply Partner

The core of the sensor lies in its sensing diaphragm, which is typically made from copper alloy. The characteristic feature of copper alloy material is its excellent elasticity, functioning like a robust yet sensitive membrane that can precisely detect minute pressure changes.

As precision instrumentation, to ensure high accuracy requirements for gas flow direction and electrical conductivity, the manufacturing process must be free of any visible scratches and water marks after surface treatment, qualifying these as high-precision components.