Adhesion/corrosion resistance/airtightness test

WKPT provides metal parts machining solutions including but not limited to machining. The machined metal parts sometimes need to be assembled with other parts into semi-finished products, and the assembly process of different parts is prone to errors. These errors not only happen in the machining process, but may also exist in the metal forming process. Therefore, after the semi-assembly process, a basic test on metal assembly parts must be carried out, and this process is called a function test.

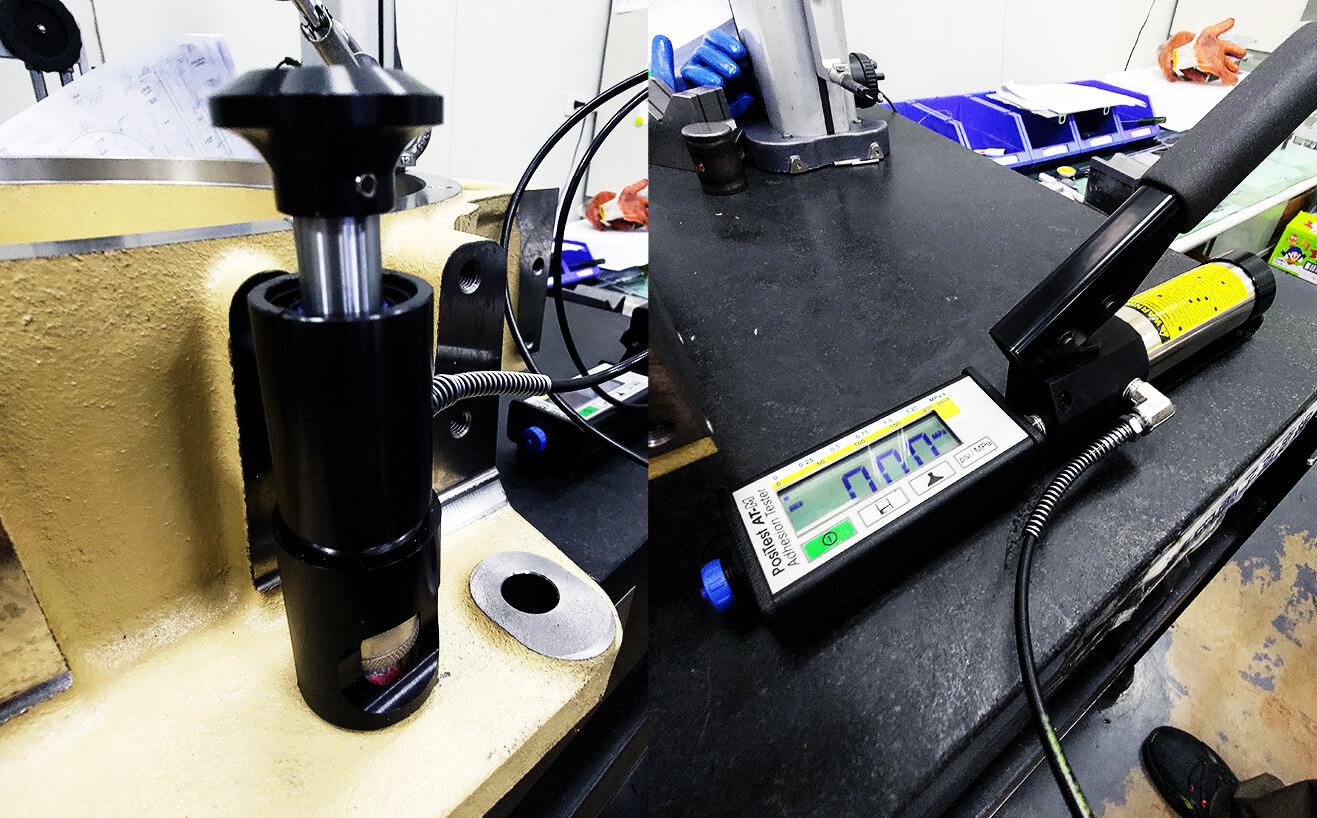

Gas leak detection is included in the function test, detecting any breakage of parts after forming, machining or assembly. At the same time, pressure tolerance of parts in gas leak detection will be also tested, to see if the buckling under wind pressure will cause structure failure or not. Meanwhile, air tightness testing is the most general test at WKPT, because the semi-assembly parts need to hold fluids or gas during the assembly process. A properly functioning assembled part needs to pass the gas leak or water leak test. It is not just gas proof or water proof, but sometimes an assembled part needs to maintain a certain air tightness for a sufficient period of time.

Function testing of metal parts also includes surface treatments during parts machining, such as powder coating and liquid coating, etc. A well-functioning coating needs to pass the coating adhesion test; however, there are a lot of external environmental factors involved in the coating process. Parts coating in different time periods is not easy to achieve the same results. Therefore, we will carry out an adhesion test for each batch of products, such as a cross cut test to verify the coating adhesion of parts. Before the products are sent to packaging and logistics, we can do rust resistance and salt spray resistance test according to our customers requirements, or ask our cooperative teams to carry out the test and verification of the withstand voltage and conductivity.