Prototype Manufacturing

The prototype is the first sample of components which is made before production for verification. For those industries that need high-precision metal parts for machinery work such as the aerospace industry, semiconductor industry, biomedical electronics, military industry, etc. Prototypes can generate more reliable products. The early metal prototype mockup was handmade due to limitations in special materials purchasing and a long molding schedule. These limits lead to a long time in prototype mock-up and difficulty in fulfilling precision requests on drawings and verification of appearance and structure.

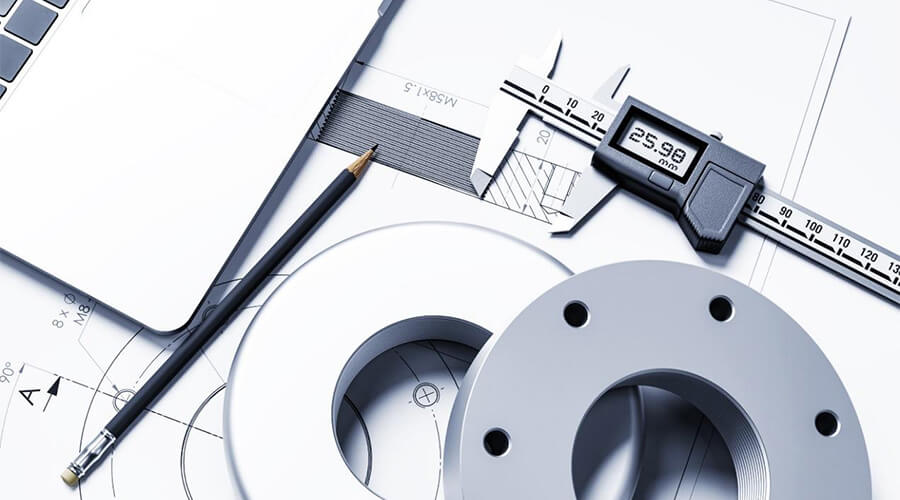

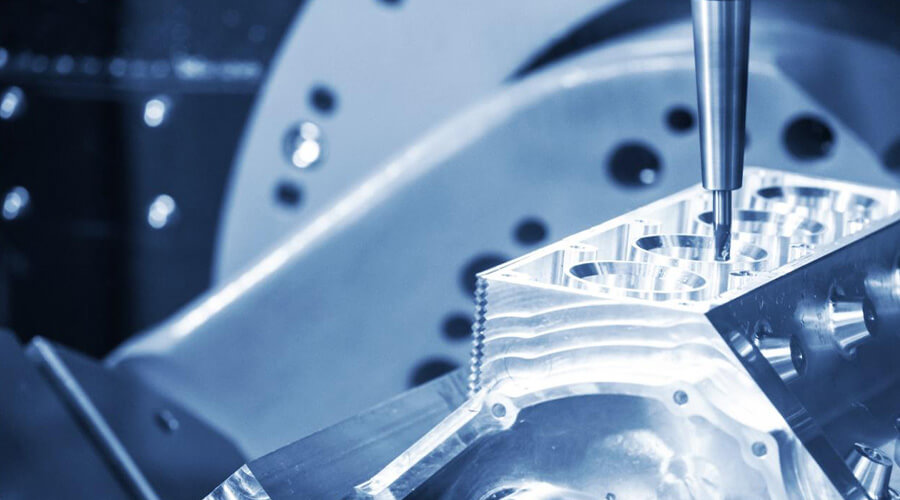

WKPT offers customized metal rapid prototyping services. We can make several prototype mockups without molding but use drawings and software design by a five-axis CNC machine. This prototype mock-up can be used for appearance and structure verification and shorten the development schedule in material development, product design, and customization. Under the digital manufacturing trend, applying digital technology can help us discover possible production problems in advance.

Responding to modern manufacturing technology, we get 3D printing technology, additive manufacturing, and rapid prototyping from the Metal Industries Research & Development Center in Taiwan.

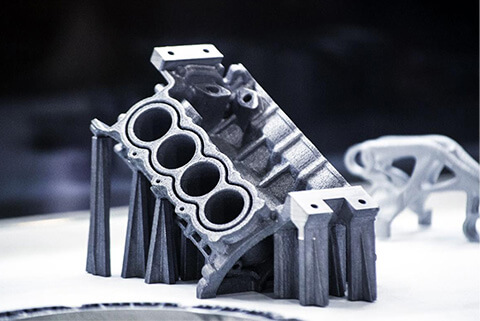

3D printing can be divided into two types, rapid prototyping, RP and rapid manufacturing, RM. WKPT applies 3D printing skills and casting to produce as-cast in the product development stage. The next step is rapid machining which finally generates the rapid-prototyping mock-up for verification. Compared with processes such as molding, sand molding, and repairing, 3D printing for development can shorten the prototyping from 30 days to 7 days. To fulfill customers' development schedules, we do prototyping mock-ups by following steps:

- Purchase metal blocks or bars that meet requirements for full engraving machining.

- Use high-precision 3D metal printing technology to print blanks that meet the material requirements.

- Use 3D sand mold printing technology and various casting molding techniques to complete the rapid prototyping.

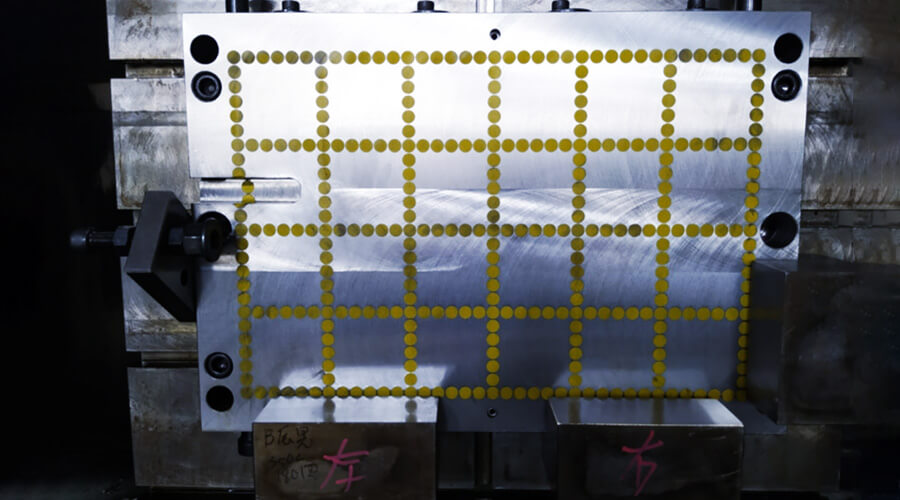

- Use modular standard jig parts and combine them into simple manual jigs to hold prototype blanks for rapid prototyping machining.

- Use precision fixed angle vise and multi-axis processing machine for multi-faceted one-time machining to avoid repeated positioning accuracy errors of fixtures.