Production Process

Metalworking is the process of shaping and reshaping metals to create parts, assemblies, and large scale structures. The historical roots of metalworking applications span thousands of years in cultures and civilizations. It has been discovered through the smelting of ores and hot forging of harder metals, the toughness and ductility of metals can be developed into useful tools.

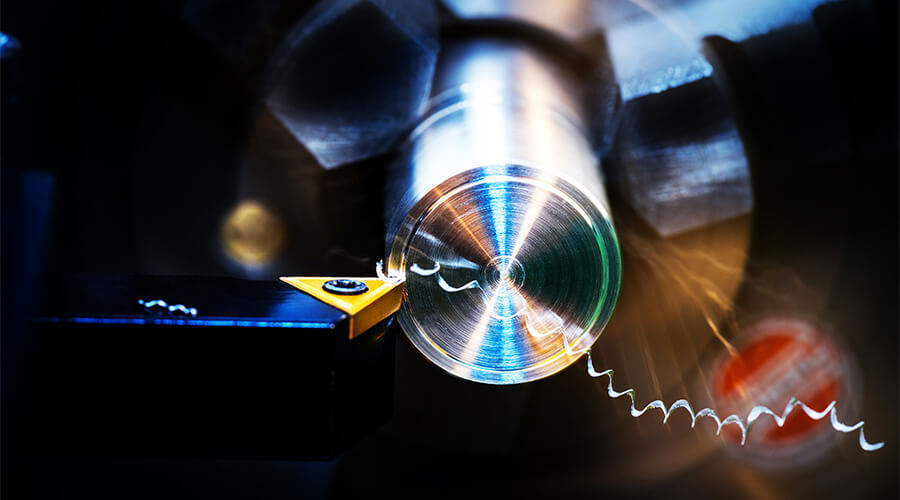

There are many kinds of modern metalworking processes, with professional and labor divisions. Mechanical tools are widely used in processes such as turning, milling, shaping, grinding, wire cutting and heat treatment, forging, casting, EDM, stamping, die casting, etc.

Precision machined parts are supplied to OEMs and system integrators, and finished parts are used in a wide range of end-market fields. WKPT has a total solution of precision machining, from metal material forming, machining, surface treatment, assembly welding, to functional testing, etc. We remove materials on metal workpieces, producing precision parts with tight tolerances and high surface quality.

The machining process mainly means changing the shape, size and features of metal workpieces by machining equipment, including turning, milling, drilling, boring, assembly and welding.

Converting precise 3D graphics to CNC programs through CAM to perform precision machining is the most widely accepted industrial model. We use CATIA CAD/CAM to simulate fixture clamping and cutting before actual machining, to confirm that all processes with accuracy and efficiency, improving the quality of the produced parts.

We use high-quality machining equipment to meet global customers’ needs. We provide precision machining solutions for various fields from automotive, hydraulic mechanism, construction machinery, green energy, agricultural machinery and aerospace industries. For special requests, we also provide various types of heat treatment, including quenching, vacuum heat treatment, nitriding, etc., to help customers achieve total process integration and quality control.

-

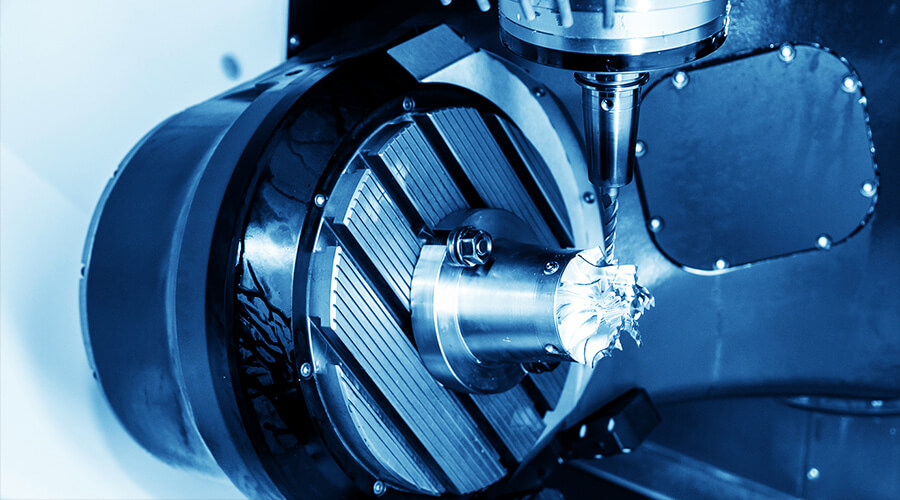

WKPT provides services ranging from metal material procurement, planning of mold, jigs and fixtures, CNC precision machining to surface treatment. On the metalworking production line, we use vertical and horizontal turning and milling machining centers to assist customers in solving the metalworking needs of high precision and complex metal parts. Our customers have benefited from our best machining solutions through the advantages of vertical and horizontal machining. We currently have more than 50 vertical and horizontal milling machining centers, CNC turning machines, and turning-milling centers, which can complete all the comprehensive machining processes at one time. Not only the current machining scale, we also continue to expand the machining center production line every year. In addition to the current high torque metalworking machines, we also expand the high-speed machining machines to strengthen the aluminum alloy high-precision machining capacity.

-

Surface treatment is the application of surface technology to metal components in order to strengthen the surface hardness or prolong the wear resistance and rust resistance of metal parts after the machining is completed. Surface treatment technology uses chemical or physical methods to form a single or multi-layer of protective materials with special properties on the surface, to increase the life of components and improve the appearance, properties and texture of products.

-

WKPT has integrated metalworking technologies from metal material forming, machining, surface treatment, assembly, welding and functional testing, etc. According to the needs of customized products, there are also corresponding manufacturing processes. In terms of assembly, there are dozens of operations involved, from the initial cleaning and protection to the final packaging. Assembly would be regarded as finished while all operations are implemented correctly on the standard operating procedure.

-

WKPT provides metal parts machining solutions including but not limited to machining. The machined metal parts sometimes need to be assembled with other parts into semi-finished products, and the assembly process of different parts is prone to errors. These errors not only happen in the machining process, but may also exist in the metal forming process. Therefore, after the semi-assembly process, a basic test on metal assembly parts must be carried out, and this process is called a function test.