Surface Finishing & Coating Services (Integrated Solutions)

Benefits of WKPT’s Surface Treatment Services

Are you looking for metal parts mass production services? WKPT provides quality-assured metal parts with IATF 16949 and ISO 9001 quality management systems. With leading lean production and smart manufacturing resources, we efficiently fulfill your entrusted projects. We integrate both in-house and external resources to provide primarily CNC machining with additional heat treatment and surface treatment mass production services of metal parts. You don't need to seek suppliers for additional processes like tempering or rust prevention; this is the added value you’ll get by entrusting machining services to WKPT.

Surface Treatment Results

Surface Treatment Capabilities

Additional supply of stress relief, tempering, and related heat treatment services for machining in order to enhance the properties of metal materials.

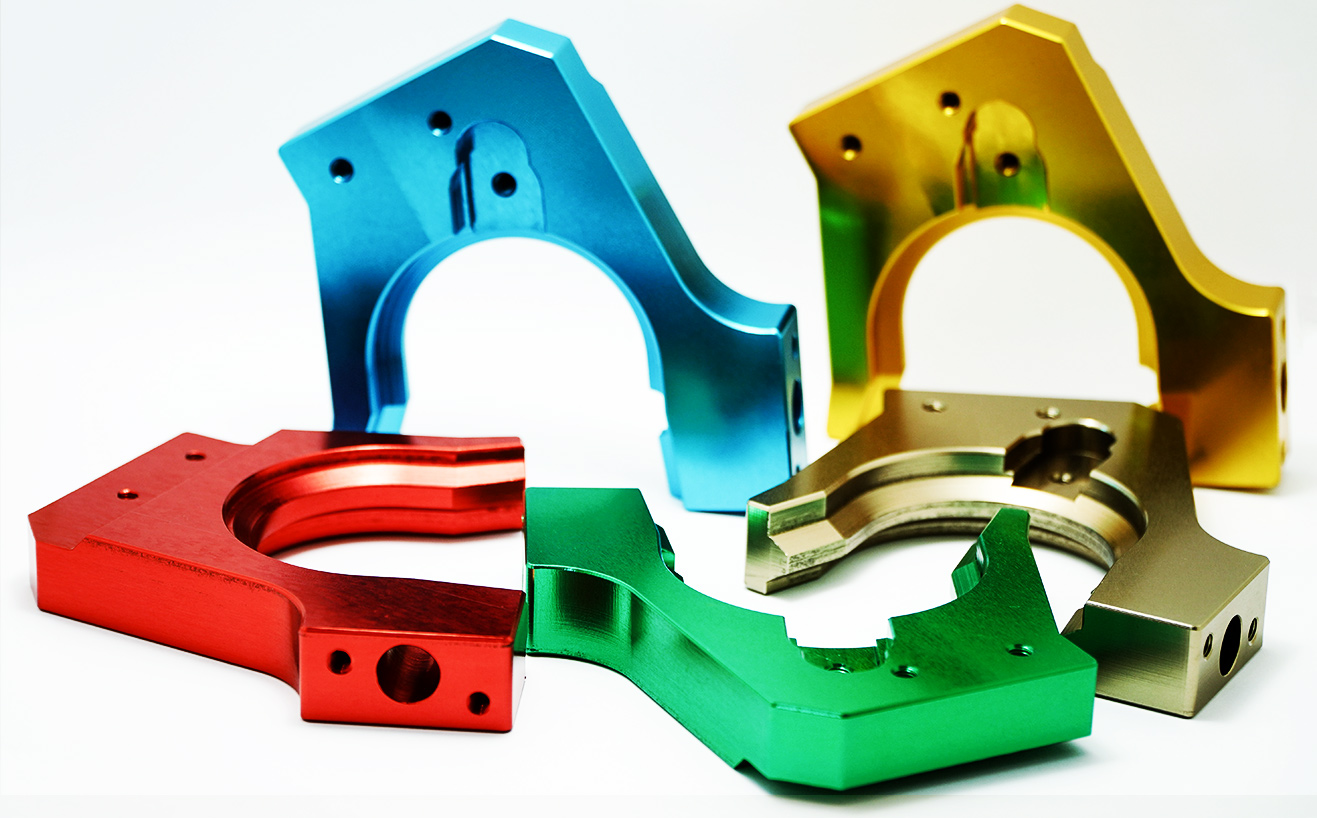

Additional supply of surface treatment services such as coating, electroplating, and anodizing for machining in order to improve the corrosion resistance and appearance of metal parts.

Materials

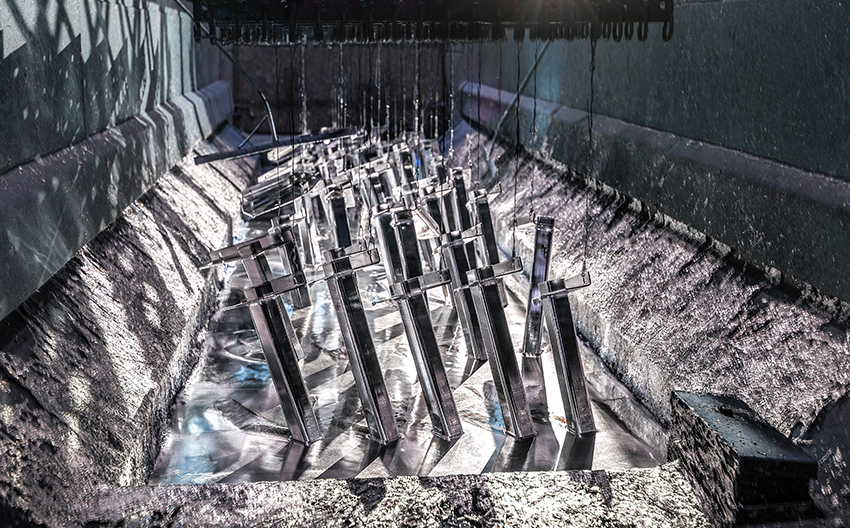

Surface Treatment Cases

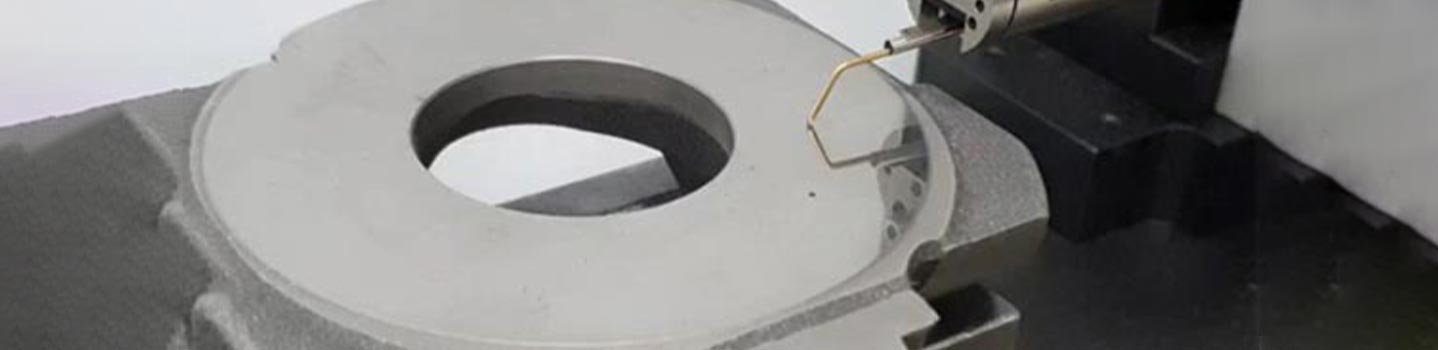

A qualified hydraulic pump swash plate must meet the requirements for surface hardness and compound layer thickness specifications. Stress relief heat treatment is carried out in the early stage of the manufacturing process, followed by surface treatment with soft nitriding in the later stage, allowing the cast iron part to achieve improved mechanical properties and wear resistance compared to the original, suitable for heavy machinery applications.

Wind turbines must withstand high salt environments, and their components must comply with the corrosion protection requirements of ISO 12944. Through coating processes of surface treatment, wind turbine brake parts can achieve corrosion resistance requirements of C3M (240 SST) or C4H (720 SST) levels.

- Surface treatment - is a manufacturing process that improves the performance and appearance of workpiece through methods such as coating or electroplating. Common coating methods include powder coating, electrostatic painting, and immersion coating, which enhance the aesthetic appearance of the workpiece. Common electroplating methods include chrome plating, nickel plating, anodizing, and hard anodizing, which enhance the aesthetic appearance and rust resistance of the workpiece.

- Heat treatment - is a manufacturing process that involves heating and cooling metal to alter its physical and mechanical properties. The outer appearance of metal materials remains unchanged after heat treatment, but their internal material characteristics are indeed altered.

Surface treatment and heat treatment are critical processes in machining. Apart from ensuring material performance and reliability, they also enhance the aesthetics, wear resistance, and corrosion resistance of metal parts. These properties obtained from surface treatment and heat treatment are indispensable in numerous industrial applications. WKPT has years of experience in mass production machining of industrial metal parts and leverages both in-house and external resources to provide additional value through surface treatment and heat treatment for forming/machining processes. Therefore, what you will get from WKPT is a highly integrated metal parts machining service.