Heavy Construction Machinery Parts Manufacturing (OEM)

Why Choose WKPT for Construction Industry?

Manufacturing components for the next generation of construction machinery requires consideration of engine air pollution emissions while simultaneously improving hydraulic system efficiency to achieve shock absorption and noise reduction effects.

Construction machinery needs to reduce fuel consumption of petrochemical fuels during operation and improve energy conversion efficiency. The next generation of construction machinery and components should focus on reducing engine air pollutant emissions in their design and manufacturing, aiming to improve hydraulic system efficiency, shock absorption, and noise reduction. WKPT integrates its supply chain, providing optimized processing technology for materials such as cast iron, aluminum alloy, stainless steel, and carbon steel. We offer a one-stop machining service for custom construction equipment spare parts, including excavator spare parts, dozer spare parts, and truck spare parts, ensuring top-quality heavy machinery spare parts for your needs.

Results

Advantage

With over thirty years of experience in manufacturing construction machine spare parts, we provide one-stop part machining services to well-known heavy machinery companies in Europe, Japan, the United States, and other countries.

Our clients include major manufacturers such as Komatsu, Sumitomo, Kubota, and their first-tier system suppliers. We produce spare parts with high strength, high elongation, and high precision.

We are certified with ISO 9001:2015, ISO 14001, and IATF 16949 certifications.

Our construction equipment spare parts manufacturing complies with the EU 2016/1628 and Japan's "OFF-ROAD Law" regulations on exhaust emissions from non-road mobile machinery. Our materials are also compatible with IMDS (International Material Data System), meeting various environmental regulations in different countries.

To meet the specifications of construction machinery, we can work with high-strength, high-elongation materials such as aluminum alloy, steel, gray iron, ductile iron, and provide comprehensive solutions including precision turning and milling, surface treatment, welding, and assembly.

Our experienced English and Japanese-speaking sales representatives can provide full-service support from product design to product delivery. In addition to our core service - machining, we also offer related manufacturing and post-processing technologies to streamline your procurement management.

Cases

Materials

Cast iron materials refer to iron-carbon alloys with carbon content more than 2.11%. In addition to carbon, there are also elements such as silicon, manganese, and a small amount of sulfur and phosphorus. Cast iron is usually made of pig iron, scrap steel, ferroalloys, etc. in different proportions through smelting.

Aluminum alloy is the general term for aluminum-based alloys. The main alloy elements are copper, silicon, magnesium, zinc, and manganese, and the secondary alloy elements are nickel, iron, titanium, and chromium.

Stainless steel, also known as galvanized iron, is the common name for corrosion-resistant steel. More specifically, steel with chromium (Cr) content greater than 12% in molten steel is called stainless steel.

Carbon steel is an iron alloy with carbon elements, that is, iron-carbon alloy. Carbon steel refers to carbon content higher than 0.02% and lower than 2% (above 2% is called cast iron, and less than 0.02% is called wrought iron).

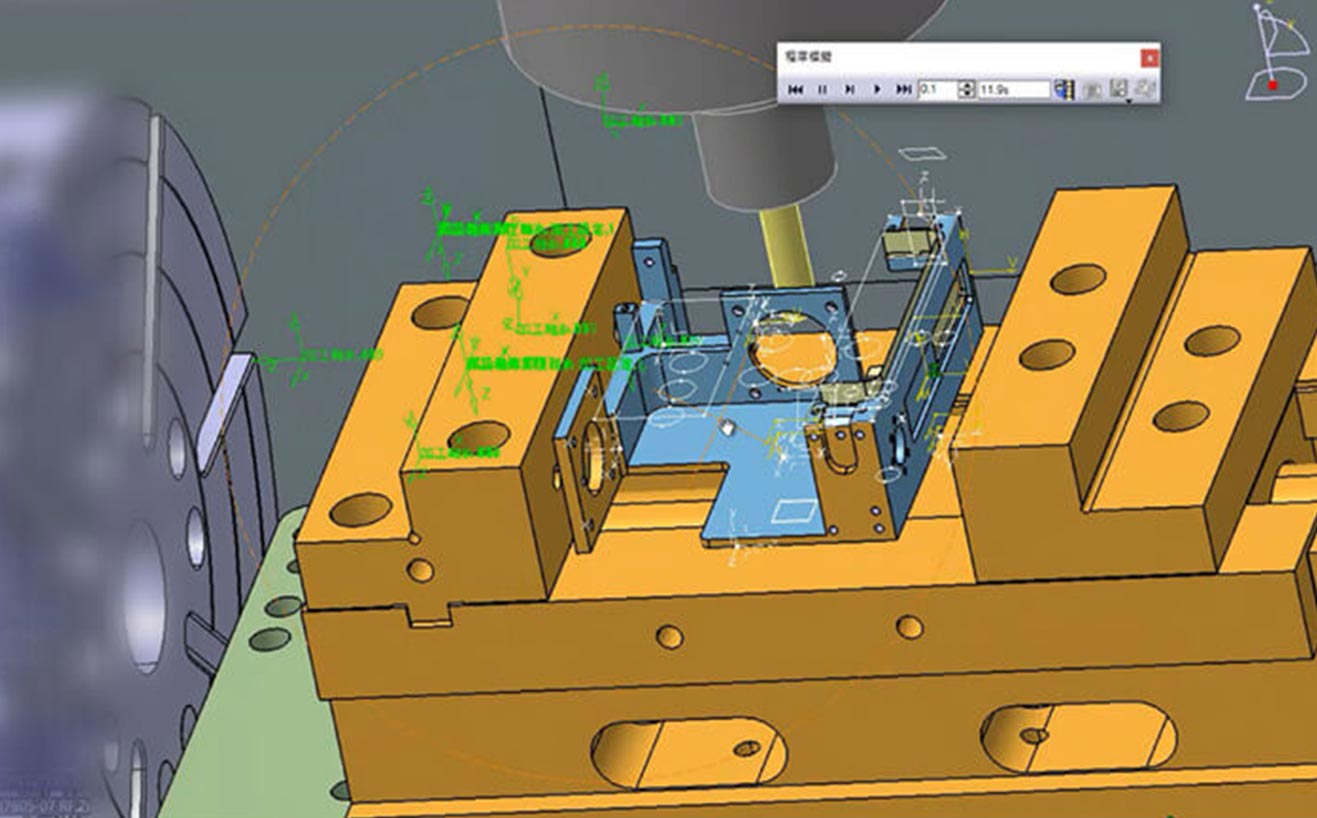

Manufacturing Capabilities

WKPT is equipped with various metal casting techniques for construction machinery parts, including sand mold casting, die-casting, gravity casting, investment casting, as well as related processes such as molding, pouring, casting, cleaning, and finishing. The types of finished products include cast iron, aluminum alloy, and more. Therefore, you can entrust us with the manufacturing of a variety of types and specifications of construction machinery parts, and receive one-stop metal machining services including casting, finishing, precision machining, surface treatment, assembly, and testing.

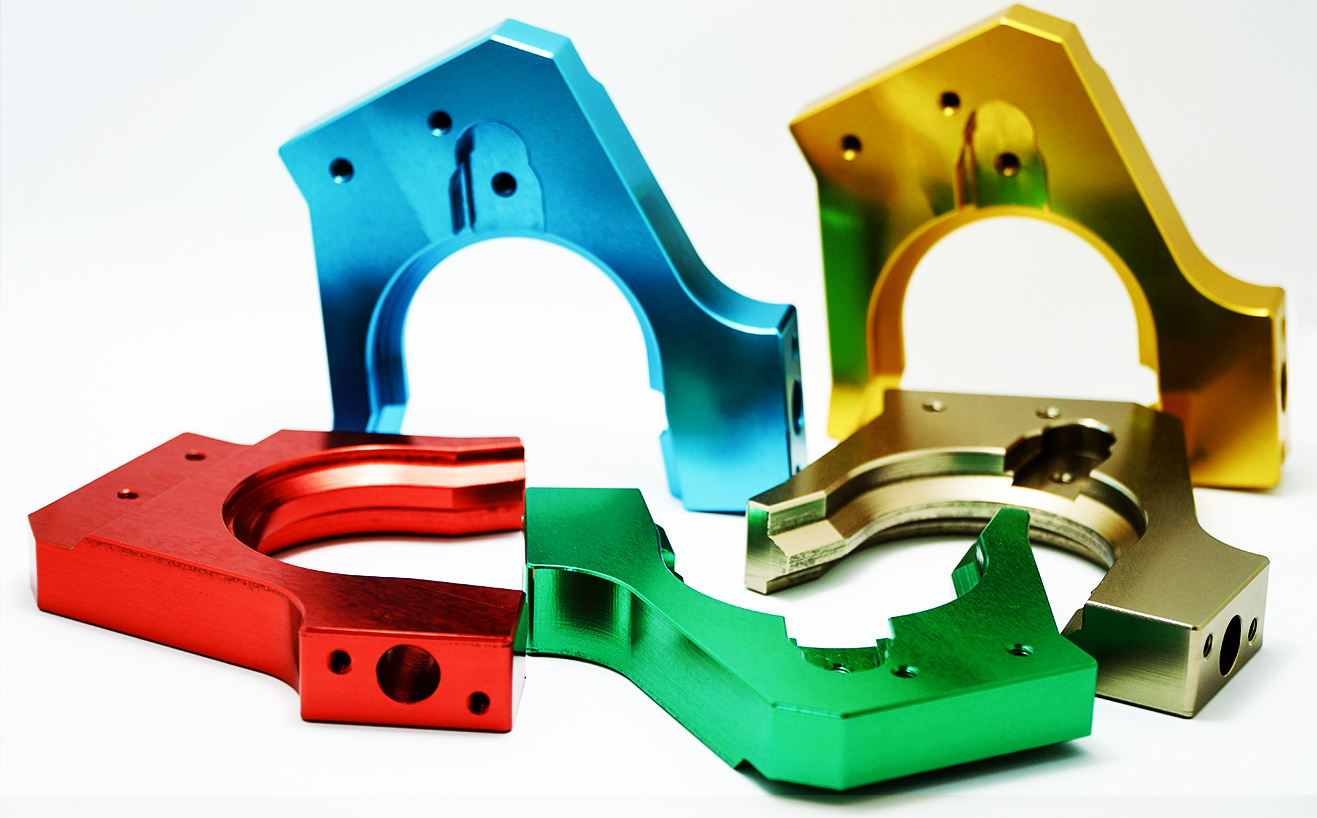

WKPT specializes in precision machining of construction machinery parts. We provide the most suitable metal parts machining services using materials such as cast iron, aluminum alloys, carbon steel, and stainless steel. No matter your parts shapes in flat surfaces, curved surfaces, grooves, gears, and other special shapes, we can make it through different machining techniques.

WKPT provides surface treatment services for construction machinery parts, including liquid coating, powder coating, electroplating, and other surface treatments. Our factory is equipped with facilities for liquid coating, suspended conveyor systems, and wastewater treatment systems for surface treatment processes.Additionally, we have developed soft nitriding treatment technology for generating hardened protective layers on the surfaces of cast iron metal parts.Through the integration of diverse surface treatment processes, we can provide value-added services to your construction machinery parts after metal forming/machining at WKPT.

More Resources

-

Alloy steel hydraulic piston manufactured from high-strength alloy steel, specifically designed for axial piston pump and motor systems. The product offers superior wear resistance and fatigue strength, serving as a critical component ensuring efficient operation of hydraulic transmission systems.

-

Medium carbon steel European coupling manufactured from carbon steel, specifically designed for hydraulic system pipeline connections. The product offers superior pressure resistance and standardized interface, serving as a critical component ensuring reliable hydraulic pipeline connections.

-

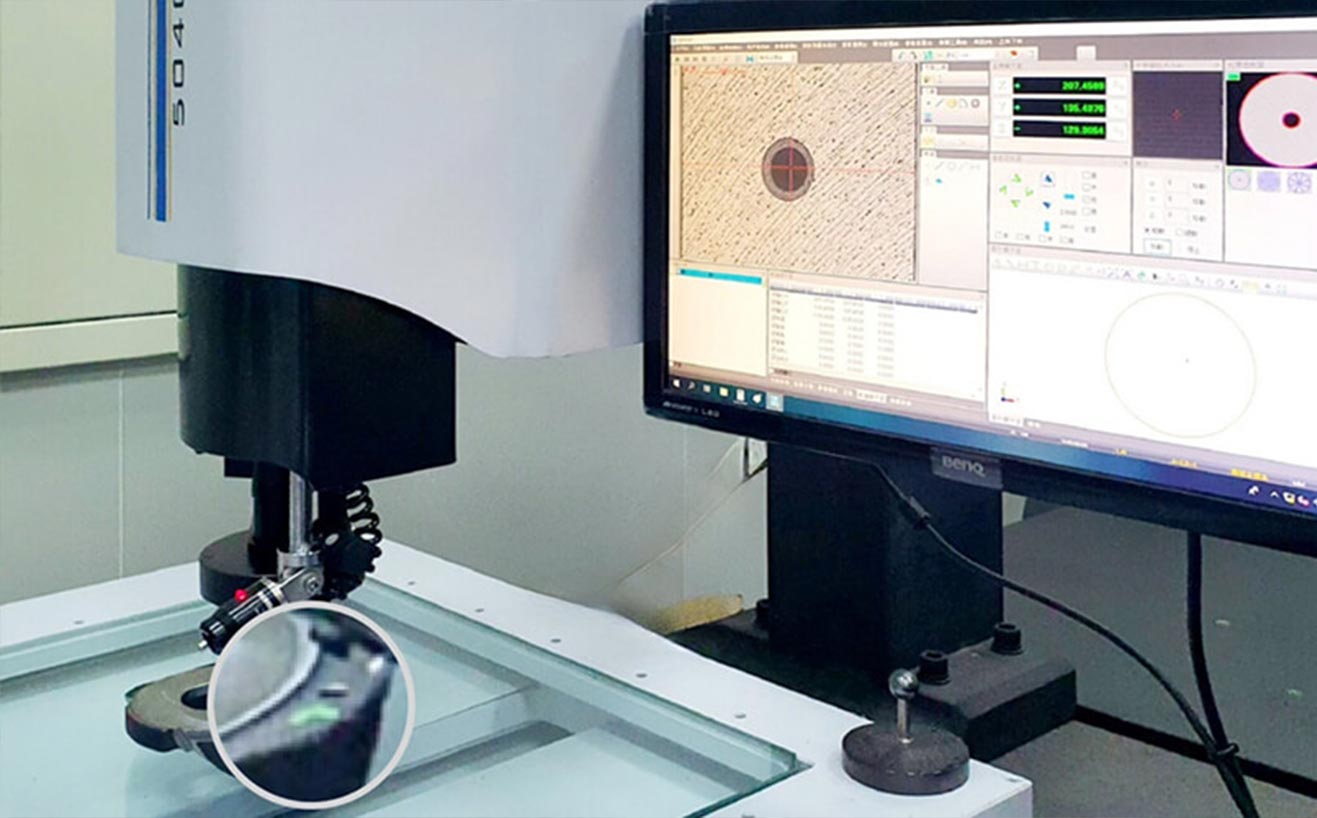

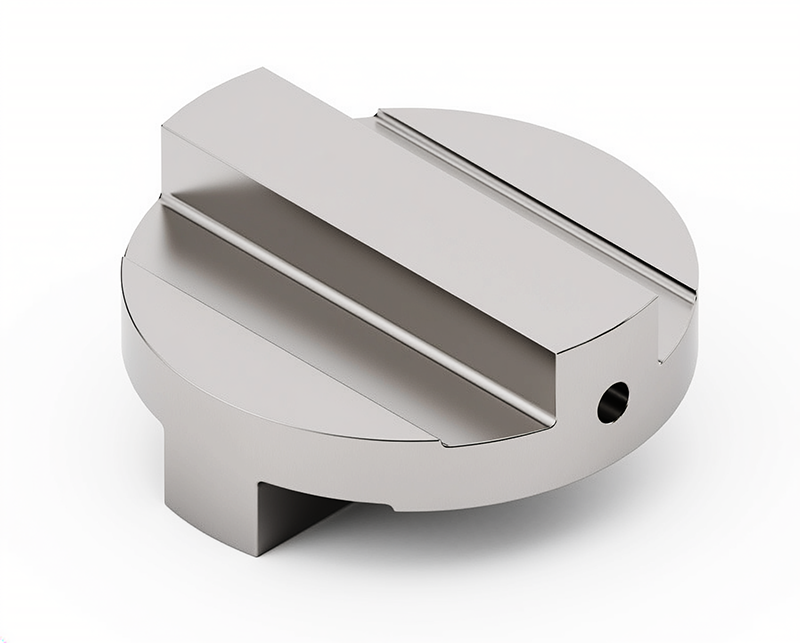

The swash plate of the oil pump has strict requirements on the size, which is not able to be done by ordinary cutting centers. To meet the customer's drawing requirements, hardness enhanced by heat treatment, and grinding process are necessary in the process. Non-contact measurement will be used on partial holes to cover where three dimensional measurements can’t do.

-

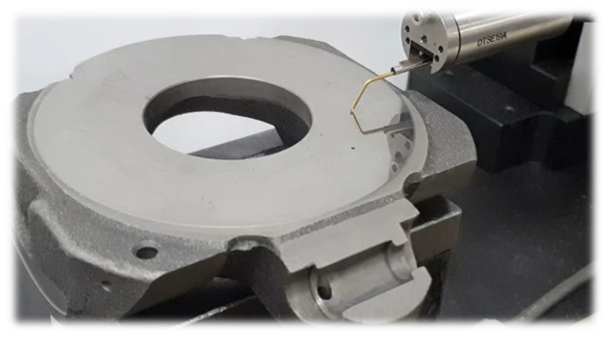

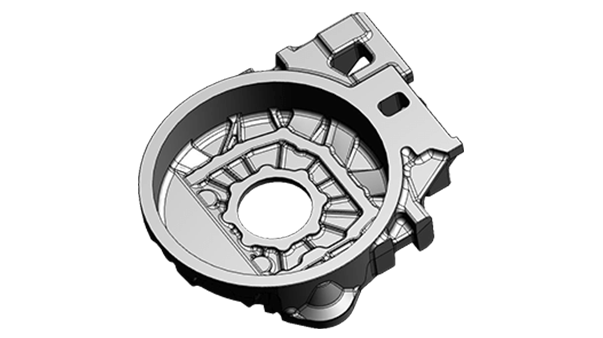

Construction machinery is used in harsh environments, especially high temperature and high strength resistance to engine flywheel housing. For this kind of product feature, tough material with solid structure is considered for manufacturing. In order to have outstanding assembly quality, there are rigorous demands on the surface of machining and casting. We have high standard checking defects and flatness, as well as surface roughness by controlling the process precisely, to reach accuracy requests.

-

Construction machinery always works under harsh environments. Its hydraulic system bears the loading of the excavator all-around, so the hydraulic cylinder is considered with high-pressure resistance. Such product properties are suitable for tough ductile cast iron without any casting defects which may leak inside. In order to increase operation stability, standard such as concentricity and surface roughness are strictly applied on machining precision. High precision specs guarantee that all processes are done precisely.