OEM Agricultural Machinery Parts & Cast Iron Components

Why Choose WKPT for Agricultural Machinery Industry?

WKPT provides manufacturing services for tractor spare parts, automated agricultural machinery spare parts, and more.

Agricultural machinery often comes into contact with substances such as chemical fertilizers, agricultural chemicals, manure, decomposed plants, and wastewater in the soil, so the metal parts need to adapt to the dynamic stress changes of agricultural machinery. WKPT controls the metal fatigue factors of agriculture equipment spare parts through processes such as material selection, surface treatment, heat treatment, and stress relief. You will find tractor spare parts and agricultural machinery spare parts with characteristics such as wear resistance, corrosion resistance, impact resistance, and fatigue resistance from WKPT.

Results

Advantage

With over thirty years of experience in manufacturing agricultural machinery parts, we’ve been a long-term supplier of global agricultural machinery brand customers in Europe, the United States, and Japan.

Our clients include major manufacturers such as AGCO and MARUYAMA, and their first-tier system suppliers. We produce parts with high strength, high elongation, and high precision suitable for agricultural machinery use.

We are certified with ISO 9001:2015, ISO 14001, and IATF 16949 certifications.

Our agricultural machinery spare parts manufacturing complies with the EU 2016/1628 and Japan's "OFF-ROAD Law" regulations on exhaust emissions from non-road mobile machinery. Our materials are also compatible with IMDS (International Material Data System), meeting various environmental regulations in different countries.

Depending on the requirements of different tractor spare parts, we can offer materials such as gray cast iron, ductile iron, structural carbon steel, alloy steel, and suitable machining process surface treatment including trivalent electroplating zinc and ED coating. to meet the wear and corrosion resistance requirements necessary for agricultural environments.

Our experienced English and Japanese-speaking sales representatives can provide full-service support from agriculture machinery spare parts design to product delivery. In addition to our core service - machining, we also offer related manufacturing and post-processing technologies to streamline your procurement management.

Cases

Materials

Aluminum alloy is the general term for aluminum-based alloys. The main alloy elements are copper, silicon, magnesium, zinc, and manganese, and the secondary alloy elements are nickel, iron, titanium, and chromium.

Stainless steel, also known as galvanized iron, is the common name for corrosion-resistant steel. More specifically, steel with chromium (Cr) content greater than 12% in molten steel is called stainless steel.

Carbon steel is an iron alloy with carbon elements, that is, iron-carbon alloy. Carbon steel refers to carbon content higher than 0.02% and lower than 2% (above 2% is called cast iron, and less than 0.02% is called wrought iron).

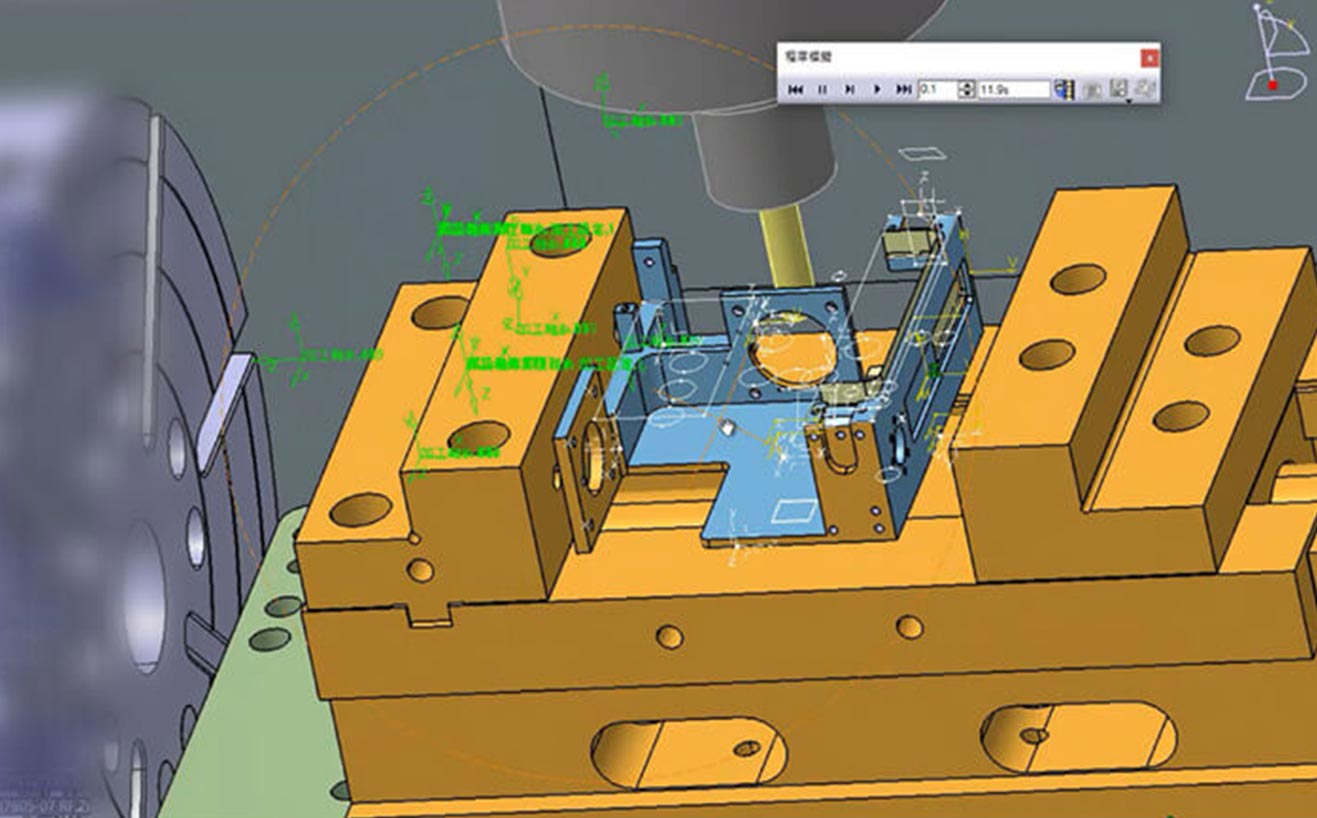

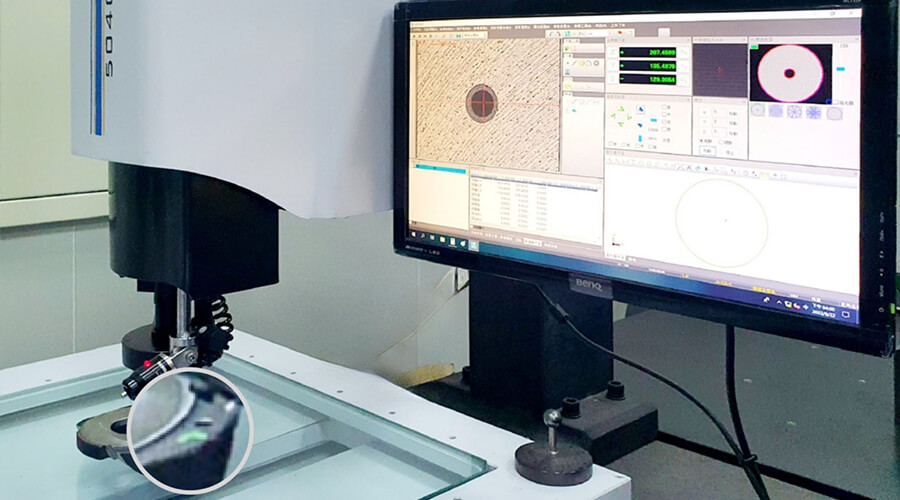

Manufacturing Capabilities

WKPT is equipped with various metal casting techniques for agricultural machinery parts, including sand mold casting, die-casting, gravity casting, and investment casting, as well as related processes such as molding, pouring, casting, cleaning, and finishing. The types of finished products include cast iron, aluminum alloy, and more. Therefore, you can entrust us with the manufacturing of a variety of types and specifications of agricultural machinery parts, and receive one-stop metal machining services including casting, finishing, precision machining, surface treatment, assembly, and testing.

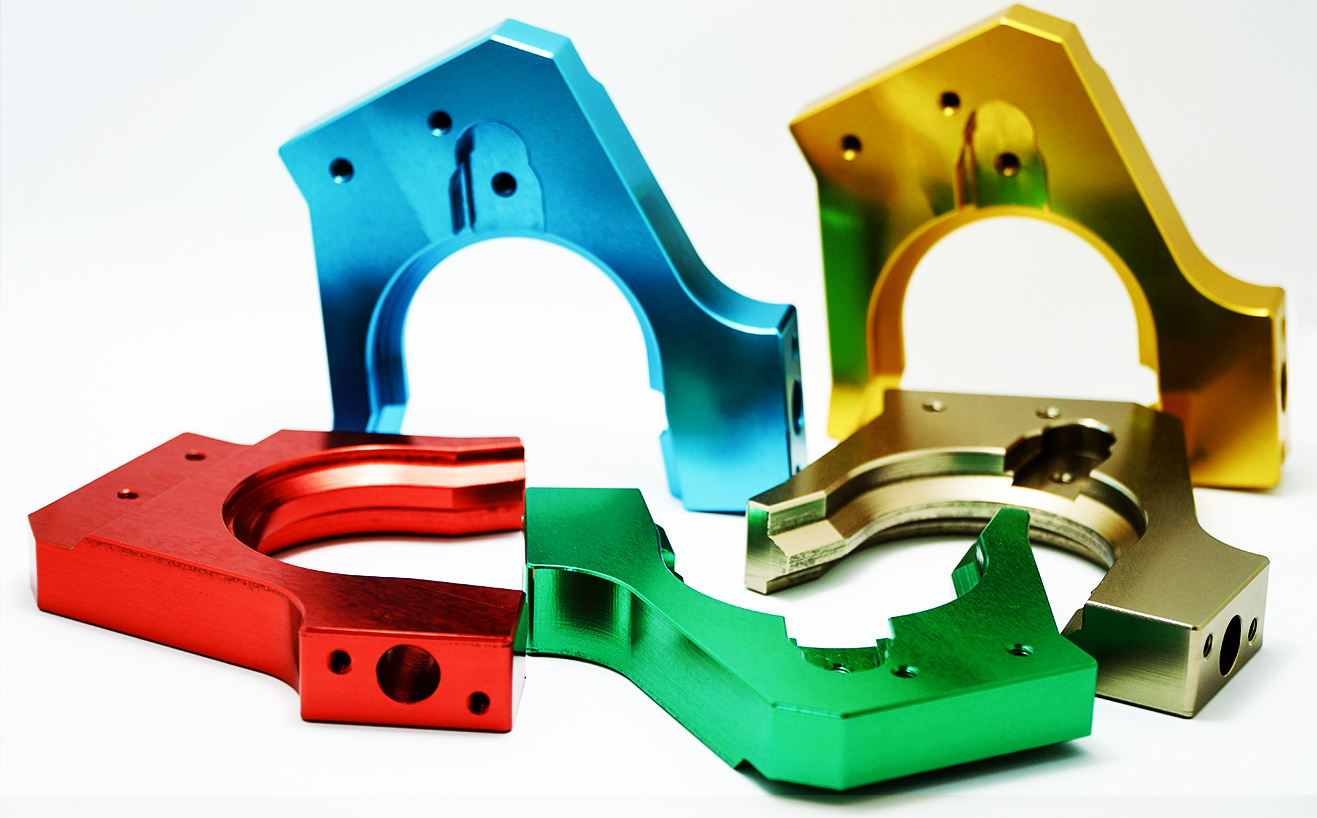

Agricultural machinery parts undergo cutting processes with different tools to obtain flat surfaces, curved surfaces, grooves, gears, and other special shapes. Machining is the main business of WKPT. We provide suitable metal components machining services for agricultural machinery using materials such as cast iron, aluminum alloy, carbon steel, and stainless steel.

WKPT provides surface treatment services for agricultural machinery parts, including liquid coating, powder coating, electroplating, and other surface treatments. Our factory is equipped with facilities for liquid coating, suspended conveyor systems, and wastewater treatment systems for surface treatment processes. Through the integration of diverse surface treatment processes, we can enhance the wear resistance, heat resistance, corrosion resistance, and fatigue strength of your agricultural machinery parts.

More Resources

-

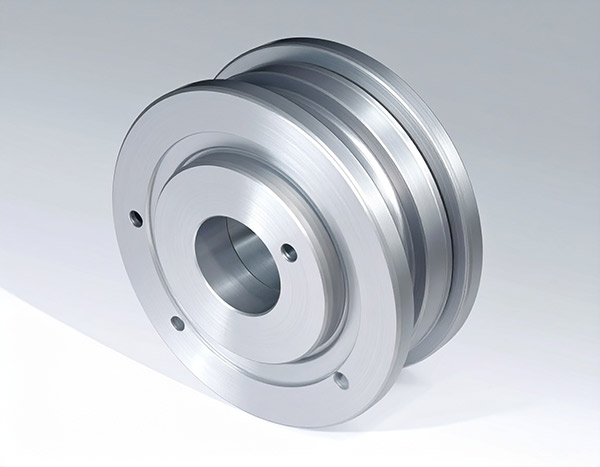

We supply high-quality cast iron pulleys for agricultural and industrial machinery. As a core component of belt drive systems, our pulleys efficiently transmit engine power, adjust speed and torque, and absorb vibrations. Made from high-strength cast iron, they offer superior mechanical strength, wear resistance, and heat dissipation, ensuring stable performance in harsh environments. Ideal for both agricultural and industrial applications, our products are engineered for power transmission efficiency and durability.

-

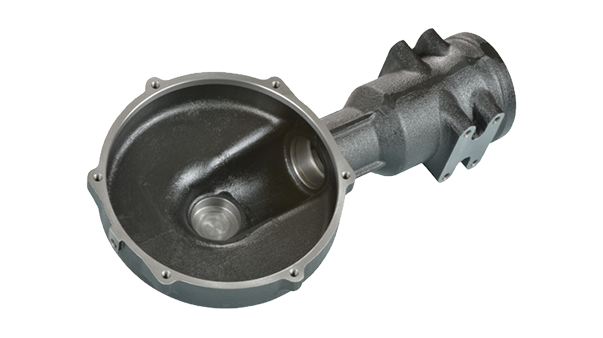

The gearbox housing is the cover of the power transmission system of agricultural machinery. It is made of ductile iron with excellent material properties. The precision and shape tolerance after machining must meet the requirements of the customer's drawing.

-

Power supply bearing is the friction part which is capable of bearing external force and vibration. So it is necessary to add other alloy into normal material as casting parts to improve overall mechanical properties.

Besides, casting defects are not allowed, especially on machining.