Automotive & Commercial Vehicle Components Manufacturing (OEM)

Why Choose WKPT for Commercial Vehicle Industry?

WKPT is the largest supplier of machining parts for commercial vehicles in Taiwan.

WKPT is the largest supplier of machining parts for commercial vehicles in Taiwan. The main production parts include shock absorber brackets, mounting brackets, torsion plates, and gearbox housings for commercial vehicle chassis axles (bridges). Brake calipers, brake brackets, brake pad backing plates, thrust plates, and wheel hubs for brake systems are also available.

Results

Advantage

With over thirty years of experience in manufacturing commercial vehicle parts, we have established long-term and stable partnerships with world-renowned commercial vehicle manufacturers. We provide one-stop machining manufacturing services for commercial vehicle parts.

Our commercial vehicle parts machining is widely recognized by world-leading manufacturers such as CUMMINS, NAVISTAR, Haldex, and Volvo.

We have the technical capability to collaborate with customers in developing new commercial vehicle parts. We also offer relevant parts development in response to the electric vehicle trend, such as electronic brake components for electric buses, servo motor housings, transmission gearbox housings, and driver housings.

We are certified in ISO 9001:2015 and IATF16949 quality management systems, providing commercial vehicle parts that meet the global automotive industry quality standards.

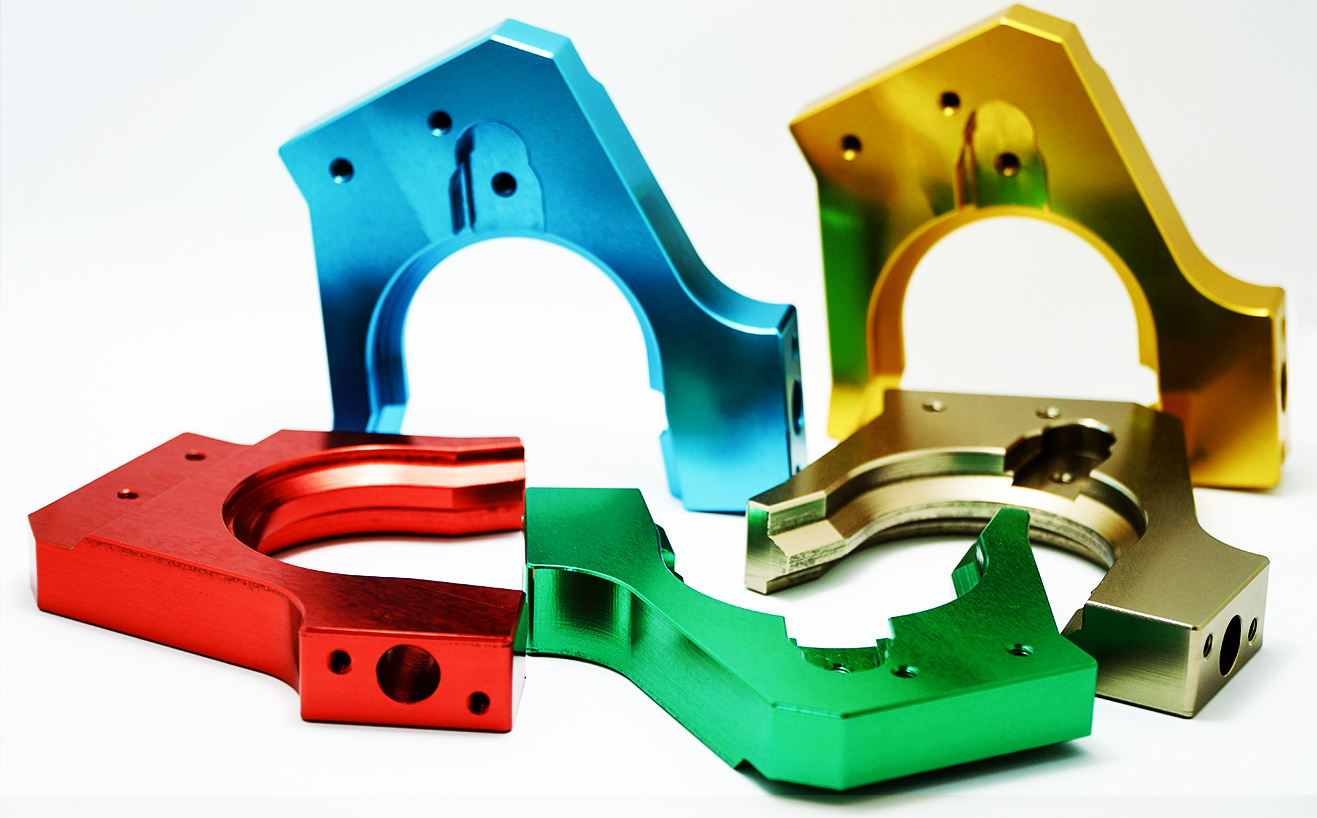

To reduce air pollution caused by emissions from fuel-powered vehicles, the trend in vehicle design is towards lightweight. Alternative energy vehicles such as electric cars and natural gas vehicles are also flourishing. In response, we have developed manufacturing processes for lightweight aluminum alloy vehicle components and are actively expanding our business in electric and natural gas vehicle sectors.

Our experienced English and Japanese-speaking sales representatives can provide full-service support from commercial vehicle parts design to product delivery. In addition to our core service - machining, we also offer related manufacturing and post-processing technologies to streamline your procurement management.

Cases

Materials

Aluminum alloy is the general term for aluminum-based alloys. The main alloy elements are copper, silicon, magnesium, zinc, and manganese, and the secondary alloy elements are nickel, iron, titanium, and chromium.

Stainless steel, also known as galvanized iron, is the common name for corrosion-resistant steel. More specifically, steel with chromium (Cr) content greater than 12% in molten steel is called stainless steel.

Carbon steel is an iron alloy with carbon elements, that is, iron-carbon alloy. Carbon steel refers to carbon content higher than 0.02% and lower than 2% (above 2% is called cast iron, and less than 0.02% is called wrought iron).

Manufacturing Capabilities

WKPT provides manufacturing services for commercial vehicle parts, utilizing materials such as cast iron (sand casting), aluminum alloy (gravity casting, die-casting, investment casting, forging, and extrusion), as well as steel. In addition to forming, we also offer comprehensive machining processes including precision machining, surface treatment, assembly, and testing.

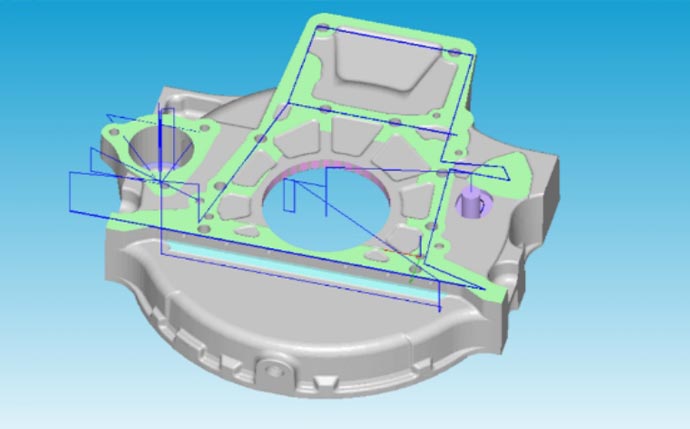

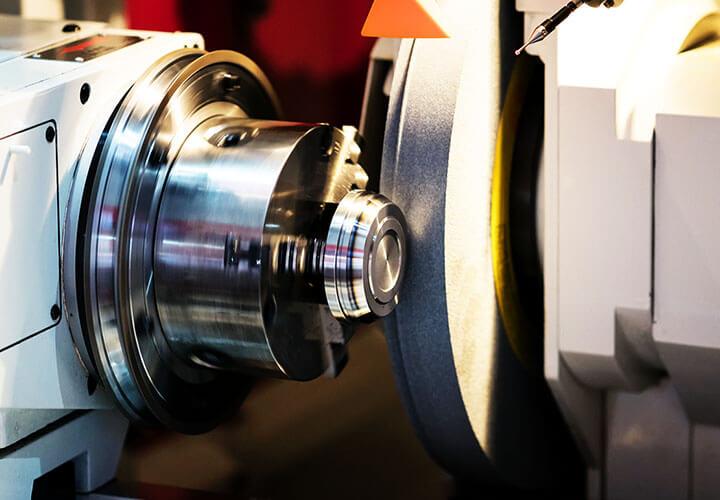

The transportation industry relies on commercial vehicles to fulfill tasks related to logistics and traffic transportation, with safety being a primary concern for most expectations. Components for commercial vehicles must adhere to strict tolerances to ensure smooth operation and minimize unnecessary wear and tear. In order to meet the requirements of commercial transportation, WKPT has developed CNC precision machining processes that meet the stringent tolerances and surface roughness required for components in the transportation industry. With machining capabilities of up to 1µm precision and surface roughness of Ra0.2µm, WKPT supplies the necessary components for the commercial vehicle sector.

In addition to safety, durability is also a concern for the commercial transportation industry, so commercial vehicle components need to meet durability expectations. Achieving greater durability for commercial vehicle components can be accomplished through heat treatment or surface treatment. Whether it's achieving better mechanical properties through heat treatment, increasing r ust resistance through coating treatments, or enhancing surface wear resistance through electroplating treatments, WKPT can provide added durability value to commercial vehicle components which are entrusted us for forming or machining.

-

Our ductile iron engine mounts are manufactured from high-strength ductile iron, specifically engineered for commercial vehicle engine support systems. These components deliver exceptional vibration resistance and fatigue durability, serving as critical hardware for secure engine installation and vibration dampening.

-

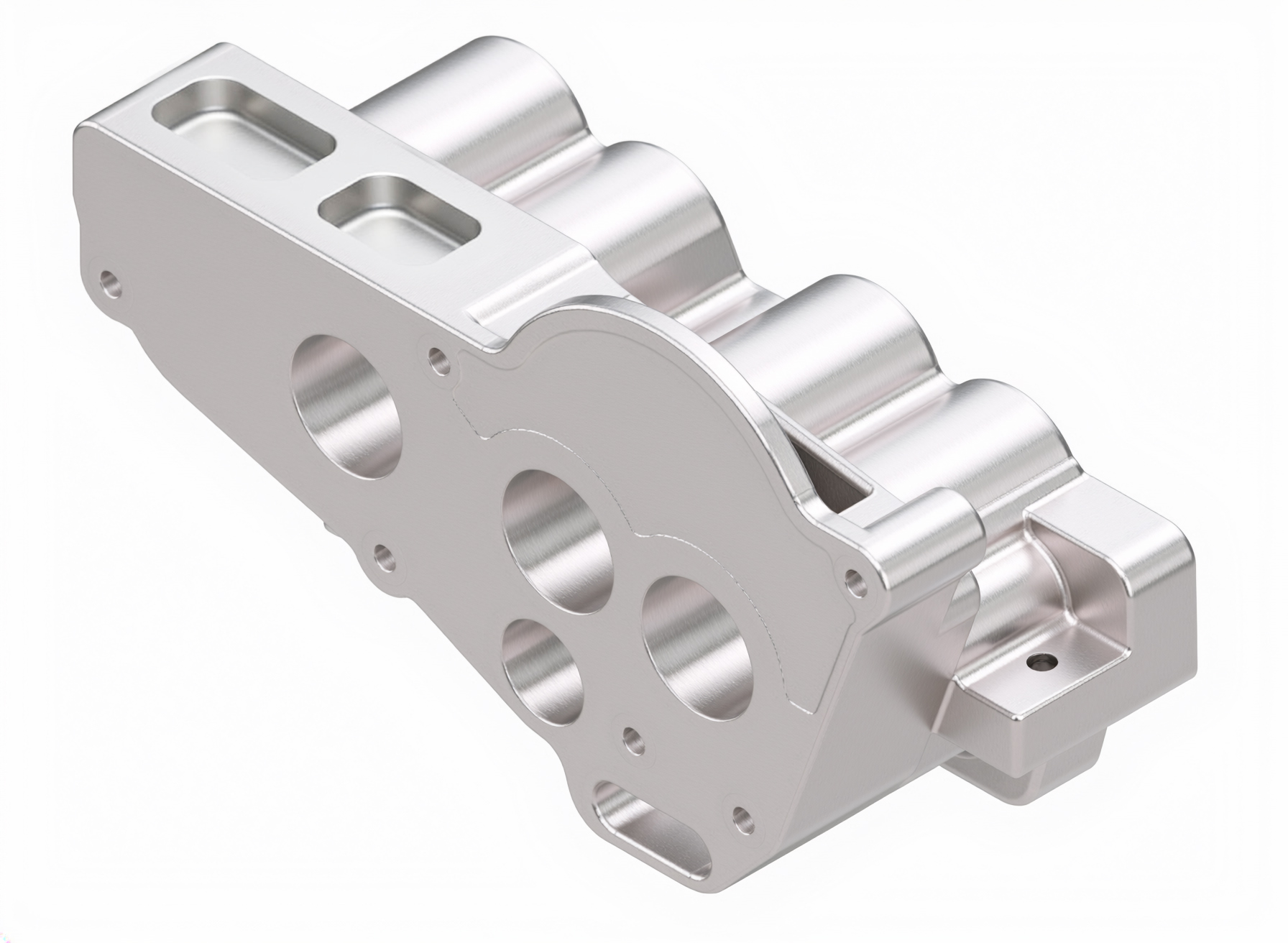

Aluminum alloy transmission solenoid valve body manufactured from high-strength aluminum alloy material, specifically designed for modern automotive automatic transmission systems. The product offers superior heat dissipation performance and precision oil passage structure, serving as a critical component ensuring smooth transmission shifting.

-

Ductile iron balance wheel bearing housing manufactured from high-strength ductile iron, specifically designed for forklift mast systems. The product offers superior vibration damping performance and load-bearing capacity, serving as a critical component ensuring smooth operation of lifting systems.

-

Our industrial brake yokes are manufactured from premium aluminum alloy, specifically engineered for heavy-duty machinery brake systems. The material offers exceptional lightweight properties and high strength characteristics, serving as the critical frame structure for ensuring stable brake system operation.

-

Our industrial brake linings are manufactured from premium aluminum alloy, specifically engineered for heavy-duty machinery brake systems. The material offers exceptional lightweight properties and superior heat dissipation, making it the critical core component for ensuring optimal brake system performance.

-

Our industrial brake flanges are manufactured from premium ductile iron, specifically engineered for heavy-duty machinery braking systems. The material offers exceptional vibration dampening and low-temperature impact resistance, making it the key component for ensuring reliable brake connection system operation.

-

Our forklift brake spacer rings are manufactured from premium ductile cast iron, specifically designed for braking systems in material handling equipment. The material offers exceptional wear resistance and vibration damping properties, making it the critical component for ensuring precise brake system operation.

-

Our forklift support brackets are manufactured from premium gray cast iron, specifically designed for load bearing systems in material handling equipment. The material offers exceptional vibration damping and machinability properties, making it the critical support component for ensuring stable forklift operation.

-

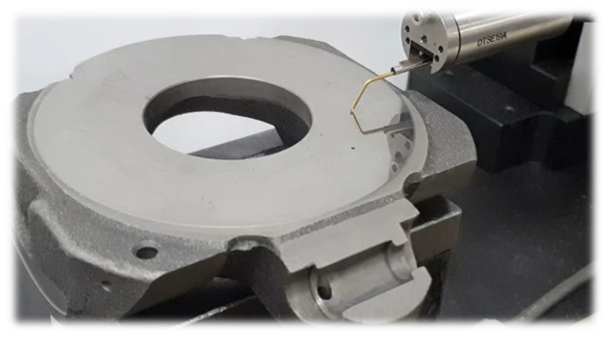

The swash plate of the oil pump has strict requirements on the size, which is not able to be done by ordinary cutting centers. To meet the customer's drawing requirements, hardness enhanced by heat treatment, and grinding process are necessary in the process. Non-contact measurement will be used on partial holes to cover where three dimensional measurements can’t do.

-

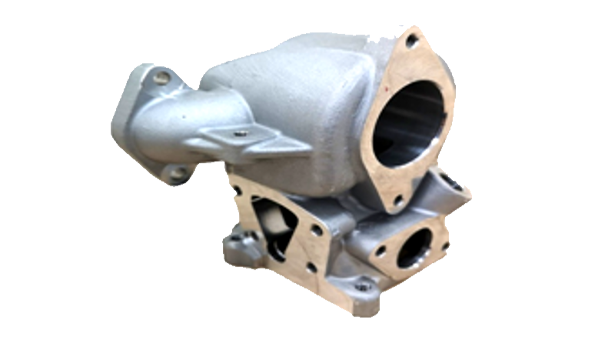

Exhaust gas manifold, EGR (Exhaust Gas Recirculation) body, or automotive secondary intake manifold, secondary exhaust gas upper manifold. The partial product shape and size is shaped by gravity casting aluminum alloy. The aluminum alloy workpiece by gravity casting has stable quality. This makes castings with high precision dimensions and finer surface roughness, which can reduce the range of machining. The exhaust gas manifold is used to guide the exhaust gas back to the intake manifold, making it inhaled and burned by the engine again. Product properties should have high temperature resistance and vibration resistance. The dimension and shape tolerance is required to be below 15μm, and the surface roughness is required to be below Ra1.6.

-

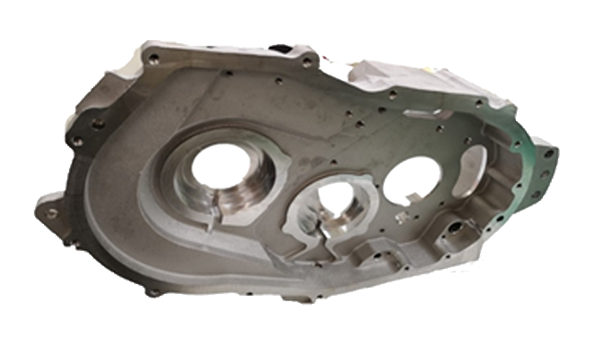

The gearbox housing is the cover of the power transmission system of agricultural machinery. It is made of ductile iron with excellent material properties. The precision and shape tolerance after machining must meet the requirements of the customer's drawing.

-

Transmission shafts represent critical precision components designed to operate in high-temperature environments and harsh operating conditions, demanding exceptional material stability and strict accuracy requirements for automotive gearbox applications. WKPT has pioneered Taiwan's first smart production line specifically for shaft manufacturing, incorporating IoT digitalization, real-time computing technology, automatic dispatching systems, and precision parameter compensation to achieve zero-defect automotive industry standards. Our advanced manufacturing capabilities combine cast iron expertise with precision CNC turning, grinding, and five-axis machining technologies, delivering transmission spindles that meet stringent automotive specifications. Through intelligent manufacturing processes and quality control systems certified to IATF 16949 and ISO 9001 standards, WKPT ensures optimal production line utilization rates and superior product yields for vehicle transmission applications requiring exceptional durability and precision performance.