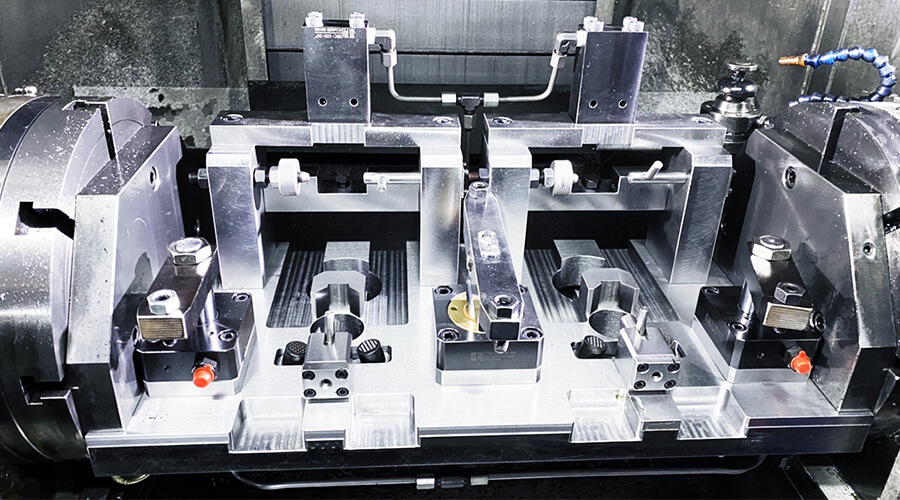

Elevating Mass Production Efficiency with Custom CNC Jigs & Fixtures

During machining, when a metal workpiece is cut by a tool, the inertial force of the tool and machine will act on the workpiece itself.

In order to keep the workpiece unmoved during the machining, a larger clamping force must be applied to stabilize the workpiece on the machine and absorb the cutting force to complete the cutting.

The device that fixes and clamps the workpiece is called a fixture.

Compared with the fixture for a workpiece, the jig is a tool to guide the workpiece.

Especially when cutting on non-planar surfaces, the jig can position the tool precisely and stabilize the cutting. However, the CNC machining fixture of the machine can omit the guiding function of the tool; only the positioning and clamping functions are available.

- Different processing methods: turning, milling, drilling, grinding, etc.

- Different types of fixtures and production methods: universal, modular, and special fixtures.

- Different clamping forces: manual and automatic.

When a new development project starts, WKPT will review and evaluate the customer's drawing specifications, precision, production capacity requirements, and special quality requirements carefully, to do APQP of jigs & fixtures. In order to achieve higher production efficiency by stable clamping, if necessary, we will send DCR (Drawing Change Request) to customers actively, such as adding clamping points or workpiece reinforcement, etc. The final goal is to design the most suitable jigs and fixtures for manufacturing based on the most reasonable fixture quotations for customers.

According to the properties of different industries, we build jigs & fixtures models with 3D software such as CATIA or SOLIDWORKS and simulate the actual way workpiece clamping and positioning. In this way, we can find out the unreasonable designs and problems in time, and effectively shorten the time for sample submission. What’s more, we can ensure a successful sample in the development stage, and offer products that meet customer needs in the batch production stage.

After the assembly of the jigs & fixtures is completed, our R&D dept. will conduct quality verification with the customer and the QA dept., inspecting the accuracy and functionality one by one, and then issue a certificate of conformity after the inspection is qualified. Only the qualified fixtures can be used on the machine for mold calibration and sample processing operations. In addition, after processing the sample, we will record the test results simultaneously and start molds, jigs, and fixtures correcting and improving immediately.

Jigs & fixtures of customers in WKPT are assigned with exclusive numbers and storage counters, and with annual inventory checks, we take the responsibility of safekeeping. In addition, after each use of the fixture, technicians will check every function. If any problems are found, they will repair them immediately to ensure the functionality of fixtures by cleaning, maintaining, and well-sealing.