Our Manufacturing Capabilities & Core Processes

-

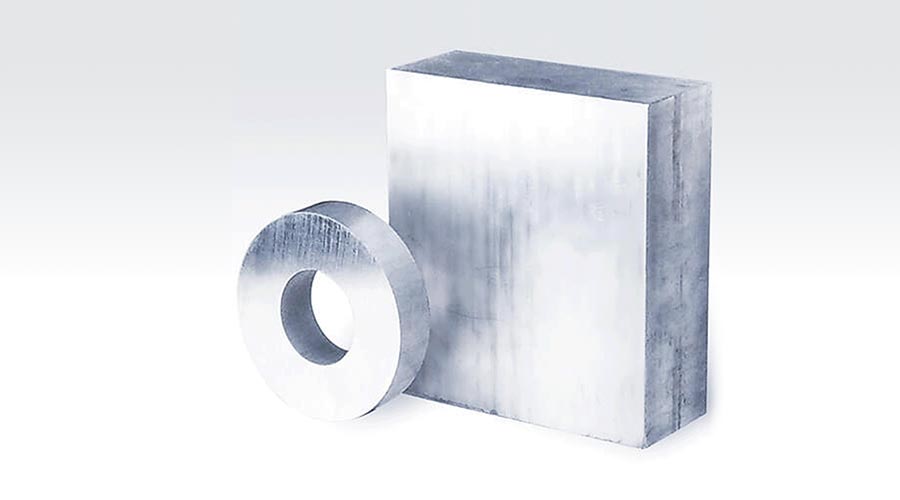

Providing metal machining services for dimensions up to 1300mm in length, 900mm in width, and 780mm in diameter.

-

Offering metal parts forming services including cast iron sand casting, aluminum alloy gravity casting, die-casting, investment casting, forging, and extrusion.

-

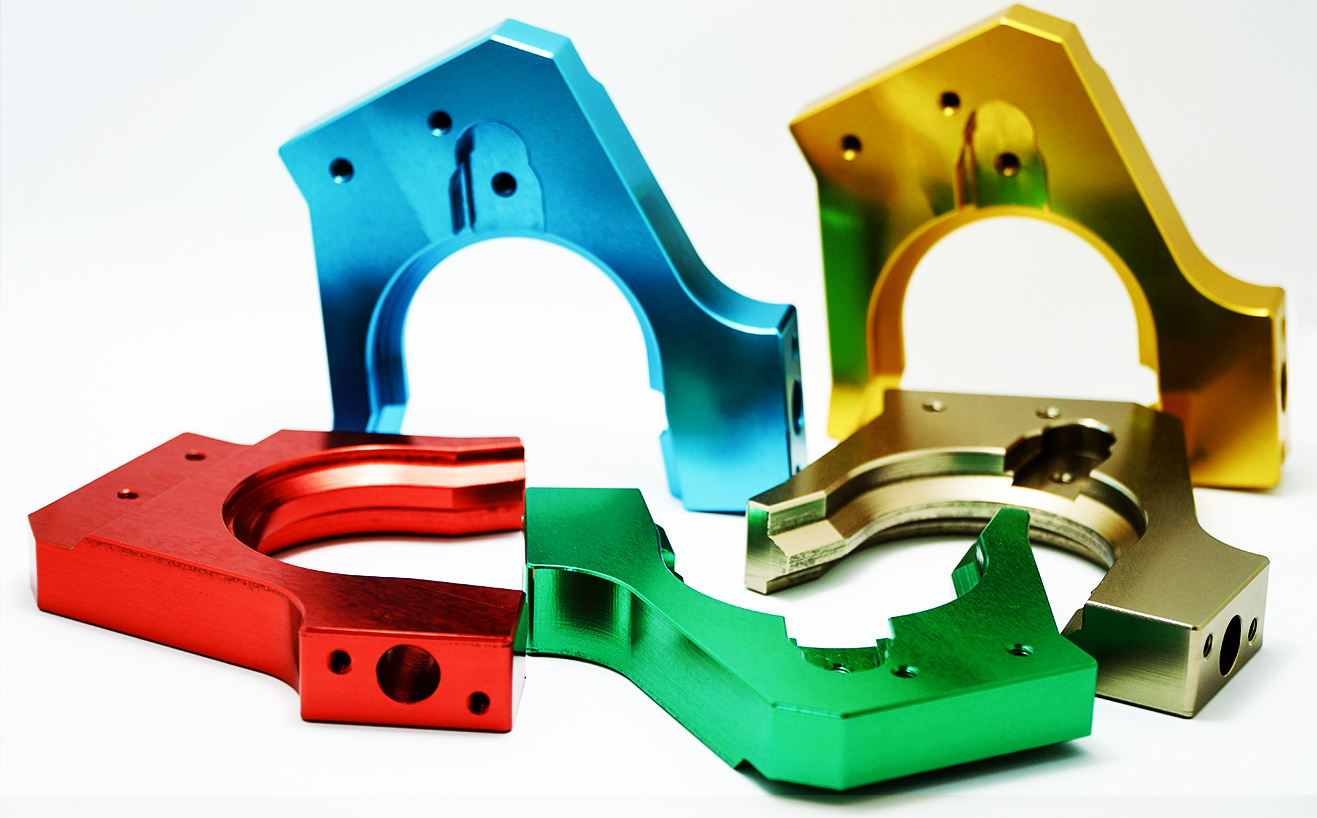

Additional heat treatment and surface treatment processes can be provided to enhance the performance of metal parts through surface processing services.

Benefits of WKPT’s Machining Services

Are you looking for metal components mass production services? We provide quality-assured metal components with IATF 16949 and ISO 9001 quality management systems. With leading lean production and smart manufacturing resources, we efficiently fulfill your entrusted projects. We integrate both in-house and external resources to offer mass production services for metal parts primarily through cutting, with additional surface treatments. With WKPT, you can save time and resources searching for specific process suppliers and simplify the procurement process.

Machining Results

Machining Capabilities

Materials

Machining Cases

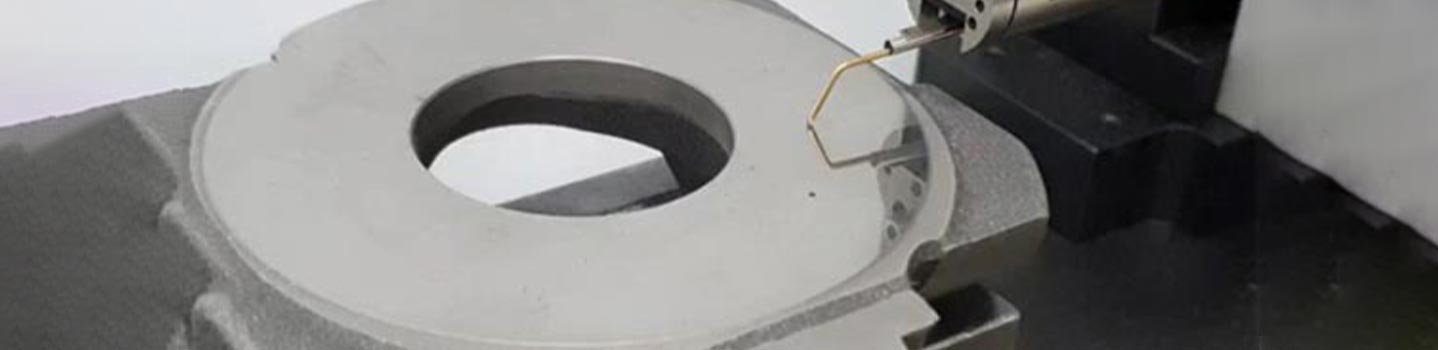

A qualified hydraulic pump swash plate must meet specifications for surface hardness and compound layer thickness, hole diameter/hole spacing/verticality, and surface roughness requirements. We conduct inspections during the heat treatment and machining processes to ensure the workpiece achieves the required precision. Especially for surface roughness requirements, we integrate the lapping techniques to achieve a smooth surface with an Ra of 0.2µm for cast iron parts and obtained invention patent of it.

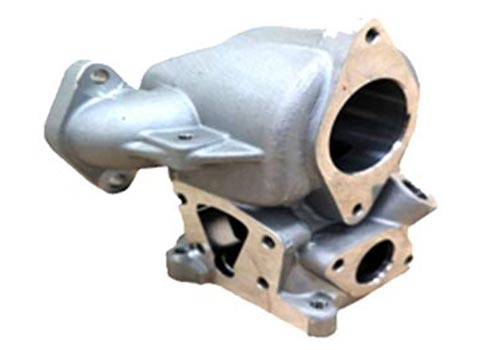

The exhaust gas manifold is used in commercial vehicles or heavy machinery and is characterized by high temperatures. Therefore, there are specific requirements for material and hardness. Inspections will be conducted during the incoming material inspection and machining processes to ensure the workpiece achieves the required precision, with a surface roughness (Ra) of less than 1.6µm and dimensional and shape tolerances of less than 15µm. Recommended materials include high-silicon molybdenum ductile iron or gravity casting aluminum alloy, which can meet the high-temperature resistance characteristics required for exhaust gas recirculation manifolds.

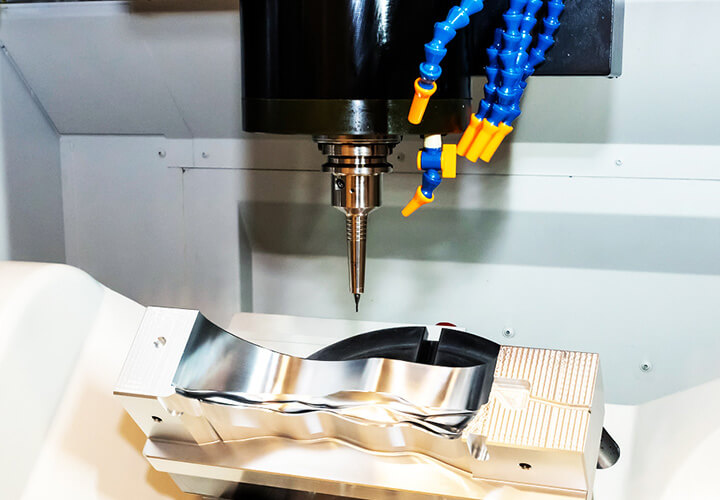

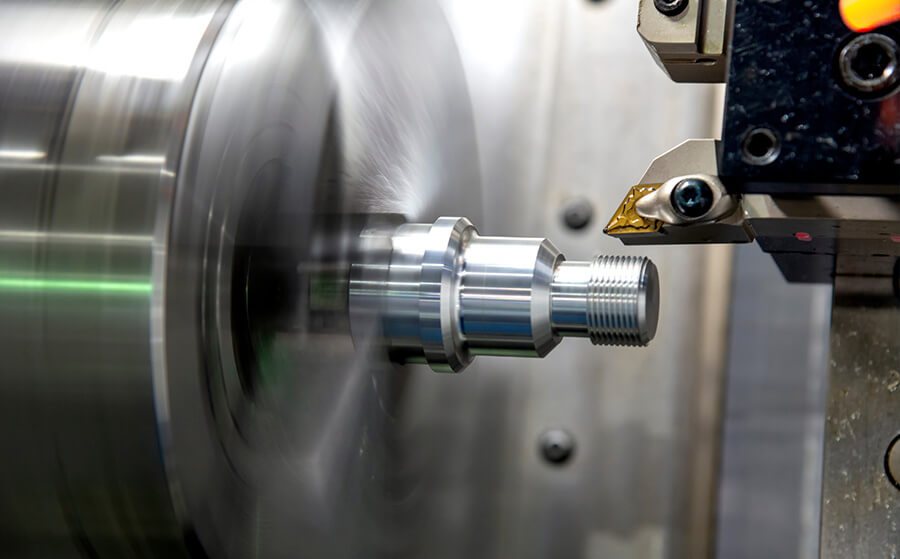

Machining is a manufacturing process that utilizes machine tools or related equipment to remove excess material from a workpiece or shape it. In comparison to additive manufacturing such as 3D printing, where material is added, the process of removing excess material is referred to as subtractive manufacturing. The process of removing excess material using machine tools is also known as machining, with common machining methods including turning, milling, grinding, boring, broaching, hobbing, drilling, and tapping. To transform raw material into the product design as depicted on drawings, proficiency in machining techniques is required to meet the product specifications. Machining is the core business of WKPT, where we excel in utilizing cutting-edge machining technologies to fabricate metal components according to your needs.