Milling

Precision CNC Milling Services - Experience the Finest Metal Machining Quality with WKPT

World Known Precision Industry Co., Ltd. (WKPT) takes pride in offering top-notch precision CNC milling services. As a reliable company in the industry, we provide comprehensive milling solutions, encompassing design, material supply, and expert machining production.

-

CNC Milling Capabilities and Material Expertise

Our metal CNC milling services cover a wide range of materials, enabling us to handle various projects with precision and efficiency. From the early days of working with cast iron and carbon steel to evolving our capabilities to include ductile iron and advanced aluminum alloys like the aerospace-grade 7 series, we have amassed decades of experience in metalworking.

We have also successfully milled materials such as carbon fiber and nickel-zinc alloys, where stringent requirements for tool rigidity, milling machine stability, and spindle speed demand the highest levels of expertise and equipment performance. Our skilled professionals possess in-depth knowledge of advanced metalworking techniques, allowing us to overcome machining temperature impacts on deformation and precision, delivering exceptional results on every project.

The

milling machine is a machinery with carbide tools that rotate at high speed to mill

the workpiece.

The

milling machine is a machinery with carbide tools that rotate at high speed to mill

the workpiece. -

Advantages of WKPT Aluminum Alloy Milling Machining

One area where WKPT truly excels is in the machining of aluminum alloys, especially aerospace-grade 7 series aluminum alloys. These alloys are known for their high strength, toughness, and excellent processing plasticity due to the presence of Zinc, Magnesium, Copper, and other elements.

Milling 7 series aluminum alloys demands a keen understanding of the material properties and precise machining techniques. Our team of experts at WKPT has honed their skills through years of experience, enabling us to achieve remarkable results in machining complex parts and achieving tight tolerances.

Furthermore, our expertise extends beyond the milling process itself. We have accumulated extensive knowledge in the design of jigs and fixtures, which plays a critical role in maintaining precision and consistency during the machining of aluminum alloys. By utilizing advanced metalworking techniques and customizing our equipment to suit specific project requirements, we have earned a reputation as a reliable solution provider for CNC metal milling services.

Thread

machining on aluminum casting through the tap tool of CNC milling machines.

Thread

machining on aluminum casting through the tap tool of CNC milling machines. -

Comprehensive CNC Milling Solutions

At WKPT, we understand that each project is unique, and we approach every task with a commitment to delivering top-quality results. With an extensive list of machining equipment, advanced cleaning methods, welding capabilities, and customized coating solutions, we offer comprehensive services tailored to our client's requirements.

Experience the difference with WKPT's custom CNC milling services and let our expertise elevate your metalworking projects to new heights.

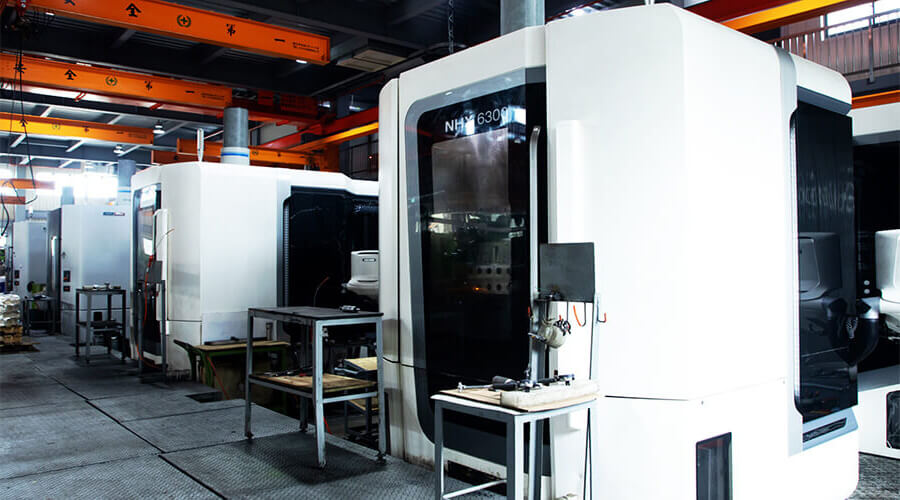

We use the DMG MORI horizontal machining center in prototyping and production of high-precision workpieces.

We use the DMG MORI horizontal machining center in prototyping and production of high-precision workpieces.

| Types of Equipment | Brand/Spec | Working Range | Q’ty | ||

|---|---|---|---|---|---|

| X Axis | Y Axis | Z Axis | |||

| Horizontal Machining Center | DMG MORI NHX-4000 | 560mm | 560mm | 660mm | 1 |

| Horizontal Machining Center | DMG MORI NHX-6300 | 1050mm | 900mm | 1030mm | 4 |

| Horizontal Machining Center | KAFO HMC-630 | 1100mm | 825mm | 885mm | 1 |

| Vertical Machining Center | Tongtai TMV-760A | 760mm | 450mm | 530mm | 1 |

| Vertical Machining Center | Tongtai TMV-850A | 850mm | 500mm | 530mm | 6 |

| Vertical Machining Center | Tongtai TMV-1100A | 1100mm | 530mm | 530mm | 4 |

| Vertical Machining Center | Champmill e-1100 | 1100mm | 610mm | 610mm | 3 |

| Vertical Machining Center | KAFO VMC-106 | 1020mm | 600mm | 635mm | 7 |

| Vertical Machining Center | KAFO VMC-137 | 1300mm | 700mm | 700mm | 1 |

| CNC Vertical Turning Center | Tongtai TVL-6DA | 760mm | - | 385mm | 2 |

| CNC Vertical Turning Center | Tongtai TVL-40 | 390mm | - | 285mm | 6 |

| CNC Vertical Turning Center | Victor Taichung VTURN-V760 | 780mm | - | 380mm | 1 |

| CNC Horizontal Turning Center | Victor Taichung Vturn-26 | 360mm | - | 600mm | 2 |

| CNC Horizontal Turning Center | Tatung OKUMA L400-E | 390mm | - | 520mm | 4 |

| 5-Axis Machining Center | Champmill C50-5A A-Axis Travel +30˚~-120˚ C-Axis Travel 60˚(Continuous) |

810mm | 700mm | 610mm | 1 |

| 5-Axis Machining Center | FFG U-600P A-Axis Rotation+110°~-90° C-Axis Rotation 360° |

460mm | 620mm | 400mm | 1 |

| 5-Axis Machining Center | Quaser UX600 | 885mm | 800mm | 500mm | 1 |

- Vertical Machining Center:

Products of machining range under length of 1300mm and width of 700mm. - Horizontal Machining Center:

Products of machining range under length of 1050mm and width of 900mm. - Vertical Turning Center:

Products of machining range under a diameter of 780mm. - Horizontal Center:

Products of machining range under a diameter of 390mm.

The distance between each aperture could be controlled under 0.01mm (special request), or under 0.02mm (normal request).

| Equipment | Spec | Q’ty |

|---|---|---|

| Ultrasonic Cleaning Machine | - | 2 |

| High-Pressure Water Jet Cutter | - | 1 |

| Equipment | Spec | Q’ty |

|---|---|---|

| Automatic Welding Equipment | - | 1 |

| Equipment | Description | Q’ty |

|---|---|---|

| Liquid Coating Line | Coating, Drying | 1 |

| Equipment | Description | Q’ty |

|---|---|---|

| Liquid Leak Detection Machine | - | 1 |

| Gas Leak Detection Machine | - | 1 |