Precision Machining for High-Performance Metal Parts

-

Does cast iron rust? Why do machine tool beds favor cast iron over steel? From gray iron to ductile iron material evolution, explore how carbon content determines mechanical properties and how modern rust prevention technologies extend the lifespan of cast iron products.

-

Why is Hastelloy chosen for secondary piping in semiconductor processes? Discover how this superalloy maintains ultra-high purity in harsh corrosive environments with hydrofluoric acid and sulfuric acid, and how precision machining techniques ensure component quality.

-

As the electric vehicle era arrives, how can transmission housings achieve both lightweight design and high strength? Discover the material revolution from cast iron to aluminum alloys, and how mold flow analysis prevents manufacturing defects.

-

The birth of metal materials originates from smelting technology. The process from iron ore to diversified applications demonstrates the crystallization of human wisdom. Carbon content, as a key factor in determining metal properties, not only distinguishes pig iron, cast iron and various types of carbon steel, but also provides diverse options for product design. Whether it is low-carbon steel with excellent toughness, medium-carbon steel with balanced strength and toughness, high-carbon steel with optimal hardness, or gray cast iron with shock absorption ability, high-strength ductile iron, they all play an irreplaceable role in modern industry...

-

Energy storage systems have become an indispensable part of modern power infrastructure. To ensure the stable operation of energy storage systems in various harsh environments, high-quality metal casings have become a key factor in the safe operation of energy storage systems.

-

WKPT discovered abnormal tool vibration during a machining process and immediately initiated a root cause analysis. The team employed the 4M1E method to comprehensively investigate the causes of the problem. This serves as one of many root cause analysis examples in the manufacturing sector. Based on the investigation results, the company designed and implemented a complete solution:

-

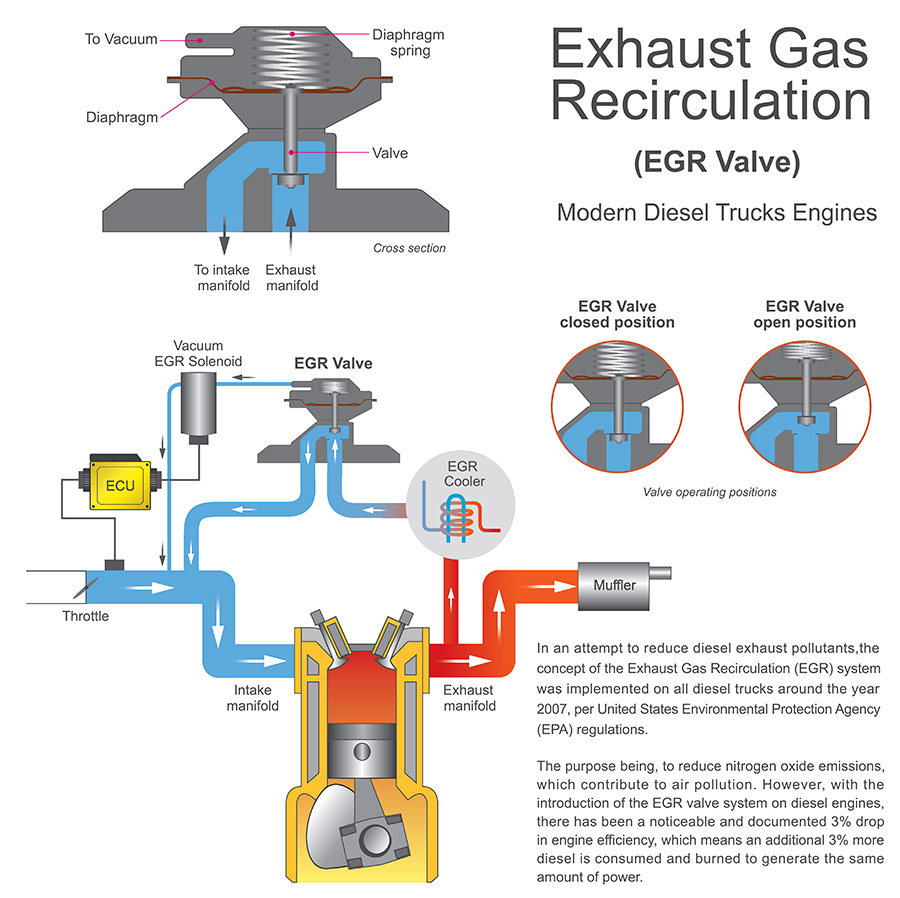

What is EGR? How does EGR contribute to environmental protection? Introduction to common EGR materials, quality standards, and development trends.

-

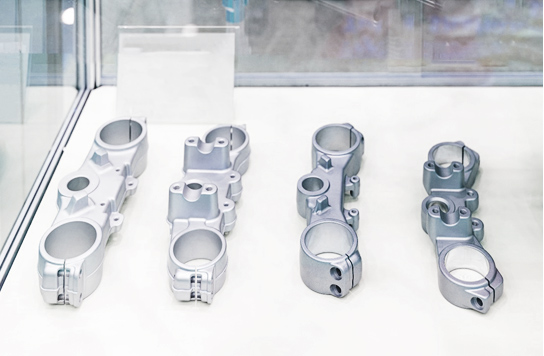

The casting industry predominantly manufactures cast iron parts, with non-ferrous metals comprising a minority share. Casting products find applications across various sectors, including transportation, agricultural machinery, construction engineering, renewable energy, and medical engineering. In the automotive and aviation industries, heightened environmental awareness has spurred the development of lightweight products to minimize energy consumption, prompting advancements in casting technology. This article provides a brief overview of the evolving development trends in casting technology in response to market demands.

-

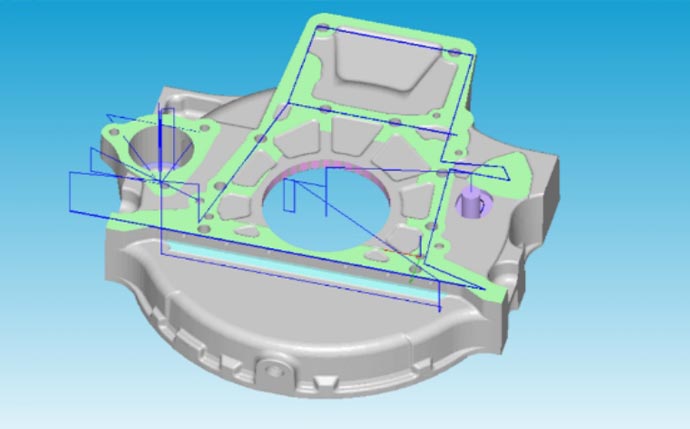

Process optimization represents a cutting-edge approach to sustainable manufacturing, utilizing advanced cutting force mechanics simulations and smart manufacturing technologies to minimize environmental impact. WKPT's innovative "Production Process Upgrade with Smart Manufacturing for Automotive Component" project employs sophisticated algorithms to analyze chip thickness, cutting force, spindle load, and tool load at each point along machining tool paths. Through precise feed rate adjustments and 3D simulation software, this technology optimizes machining programs to reduce unnecessary power consumption, protect equipment, and significantly lower carbon emissions while maintaining superior product quality and precision.