Wind Turbine Brake Components & Yaw System Parts (OEM)

Why Choose WKPT for Wind Energy Industry?

WKPT is the only supplier of wind energy brake cylinders in Taiwan

WKPT is the only supplier of wind turbine brake cylinders in Taiwan. We manufacture various components for wind turbine gearboxes, yaw (disc) brake system parts, emergency (disc) brake system parts, hydraulic systems, and turbine bases, providing wind energy equipment components manufacturing to original equipment manufacturers (OEMs) and those Tier-1 supply chain.

Results

Advantage

Whether it's onshore or offshore wind turbine, in response to extreme weather and marine conditions, WKPT's manufacturing capabilities enable the production of parts resistant to temperatures as low as -20°C. From forming, design to machining processes, we can meet all machining requirements of end customers.

In response to severe marine conditions, WKPT can provide ductile iron materials with superior low-temperature impact resistance compared to EN-GJS-LT, and continuously research the impact toughness of ductile iron for conditions ranging from -40°C to -60°C. The benefit of outsourcing wind turbine components to WKPT is that even corrosion protection coatings of ISO12944 C3M/C4H standards can be seamlessly handled along with it.

WKPT is certified through ISO 9001:2015 and IATF 16949. Parts produced through international quality management systems have passed quality assurance, which also contributes to the safety and lifespan of wind turbine equipment.

WKPT recognizes the importance of developing green and low-carbon energy sources. Therefore, we are committed to providing manufacturing services for wind energy equipment components, assisting in the localization of wind energy parts production. WKPT has also implemented the ISO 14001 environmental management system, demonstrating its commitment to environmental protection by reducing resource waste through the reduction of material and energy consumption.

We have experienced sales personnel proficient in English and Japanese who can provide you with end-to-end services from the design to the delivery of wind energy components. In addition to core manufacturing services for precision components, we also offer related post-processing services to streamline your procurement process.

Cases

Materials

Cast iron materials refer to iron-carbon alloys with carbon content more than 2.11%. In addition to carbon, there are also elements such as silicon, manganese, and a small amount of sulfur and phosphorus. Cast iron is usually made of pig iron, scrap steel, ferroalloys, etc. in different proportions through smelting.

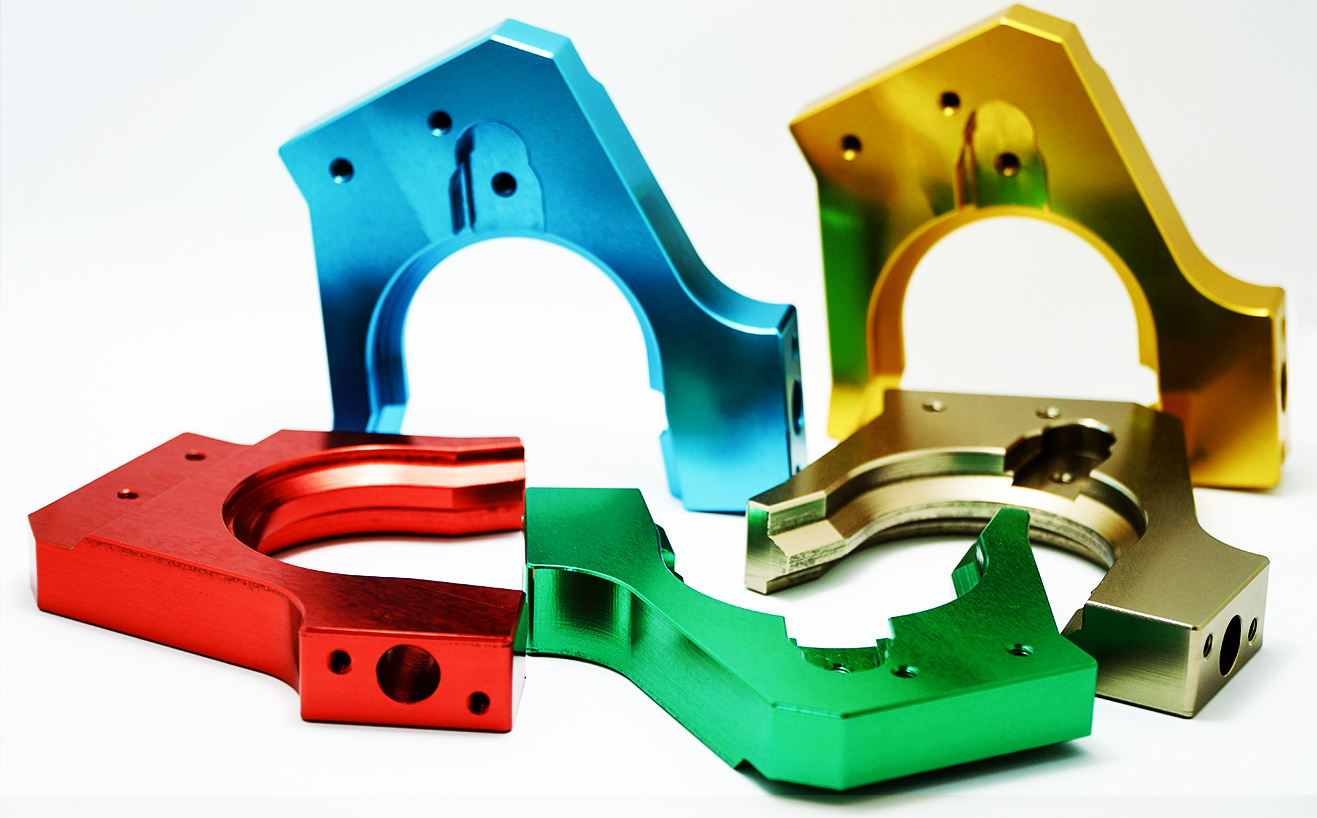

Aluminum alloy is the general term for aluminum-based alloys. The main alloy elements are copper, silicon, magnesium, zinc, and manganese, and the secondary alloy elements are nickel, iron, titanium, and chromium.

Stainless steel, also known as galvanized iron, is the common name for corrosion-resistant steel. More specifically, steel with chromium (Cr) content greater than 12% in molten steel is called stainless steel.

Carbon steel is an iron alloy with carbon elements, that is, iron-carbon alloy. Carbon steel refers to carbon content higher than 0.02% and lower than 2% (above 2% is called cast iron, and less than 0.02% is called wrought iron).

Manufacturing Capabilities

WKPT uses cast iron, steel, and aluminum alloys as materials to provide various types and specifications of wind energy equipment parts manufacturing. We have one-stop machining services such as forming, finishing, precision machining, surface treatment, assembly, and testing.

In the post-processing stages of wind energy equipment components, WKPT offers surface treatment services such as liquid coating, powder coating, anodizing, and hard anodizing. Our facility is equipped with liquid coating facilities, suspended conveyor systems, and wastewater treatment systems to enhance the wear resistance and corrosion resistance of wind energy equipment components.

-

Aluminum alloy brake lever manufactured from high-strength aluminum alloy, specifically designed for torque transmission in industrial braking systems. The product offers superior lightweight characteristics, serving as a critical component ensuring efficient operation of braking systems.

-

Wind turbine brake parts manufacturing demands exceptional material engineering and precision machining capabilities to ensure reliable operation in extreme environmental conditions across land-based and offshore wind energy applications. WKPT holds the exclusive position as Taiwan's sole supplier of wind turbine brake cylinders, utilizing specialized ductile iron materials with superior low-temperature impact resistance exceeding EN-GJS-LT standards, enabling continuous operation at temperatures far below 0°C. Our comprehensive manufacturing process addresses the unique challenges of heavy workpieces requiring large-scale machining equipment, strict dimensional tolerances, and complex geometries featuring long, deep holes that necessitate specialized tooling solutions. Through advanced surface coating treatments and rigorous 720-hour salt spray resistance testing, WKPT delivers complete brake system solutions including piston components, O-rings, oil seal assemblies, and brake pad design, manufacturing, and assembly services. These critical safety components serve diverse industries including land wind energy, offshore wind energy, industrial brake systems, construction machinery, marine vessels, and offshore heavy industry applications where reliable braking performance is essential for operational safety and equipment protection.