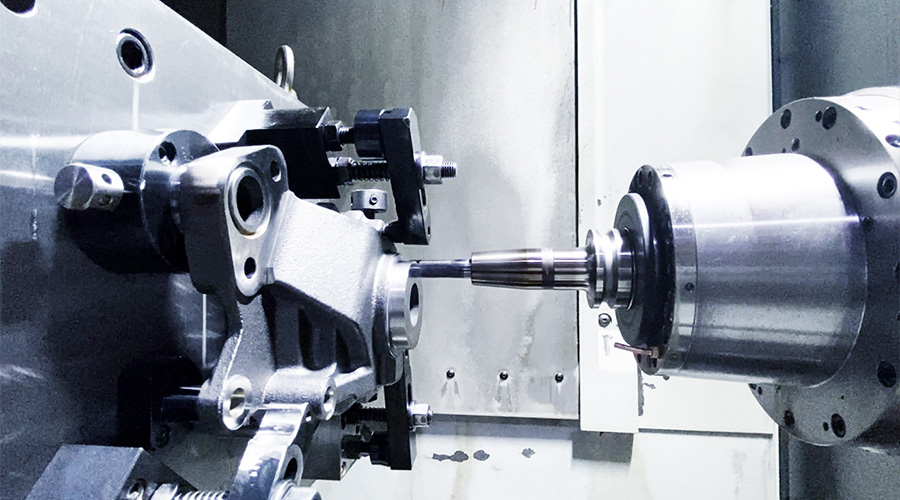

Precision parts manufacturing production line

WKPT provides services ranging from metal material procurement, planning of mold, jigs and fixtures, CNC precision machining to surface treatment. On the metalworking production line, we use vertical and horizontal turning and milling machining centers to assist customers in solving the metalworking needs of high precision and complex metal parts. Our customers have benefited from our best machining solutions through the advantages of vertical and horizontal machining. We currently have more than 50 vertical and horizontal milling machining centers, CNC turning machines, and turning-milling centers, which can complete all the comprehensive machining processes at one time. Not only the current machining scale, we also continue to expand the machining center production line every year. In addition to the current high torque metalworking machines, we also expand the high-speed machining machines to strengthen the aluminum alloy high-precision machining capacity.

In addition to the XYZ three-axis machining capabilities, the milling machine also adds a fourth axis (rotation axis) to provide multi-axis flip machining capabilities. Part of machining equipment has the fifth axis (4+1 axis), which provides five-axis orientation and five-sided positioning machining. With flexible rotation of the five-axis machine, complex workpieces machining would not be a problem anymore. Compared with the three-axis processing machine, flipping, pick-and-place, loading and unloading are required when machining, the five-axis vertical machining center can integrate various processes of complex workpieces on the same equipment for one-time multi-faceted machining. This can reduce errors and time-consuming repositioning, reducing costs and improving manufacturing quality. The five-axis machining center can meet the precision requirements of customers, especially when the machining angle of the workpiece is restricted, such as wind energy equipment parts, construction machinery parts or other special parts.

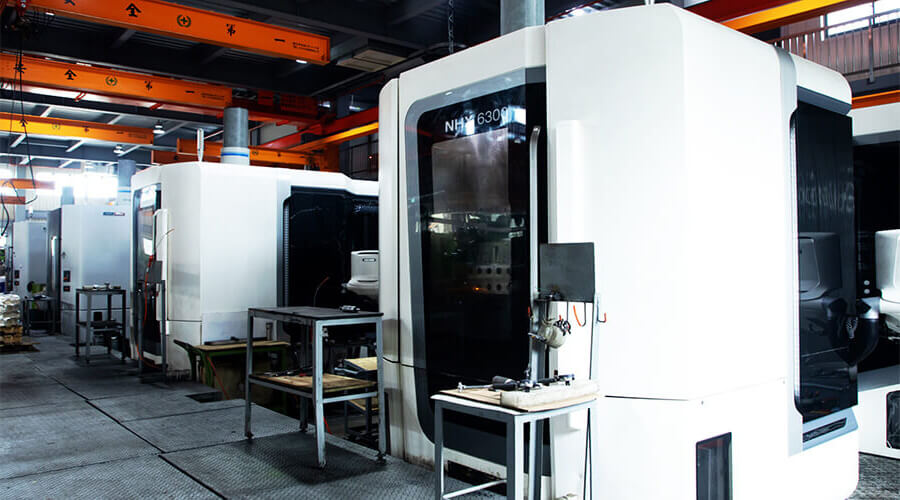

In manufacturing of semiconductor equipment components and electronic components, we use DMG MORI high-tech horizontal milling machining center for high precision workpieces prototype and production for customers. It has advanced machining technology of high dynamic performance, high rigidity, high precision and core of automation. According to the complexity and requirements of the workpiece, the standard automation system will be started, or customized automation solution upgraded for a flexible production system.

| Types of Equipment | Brand/Spec | Working Range | Q’ty | ||

|---|---|---|---|---|---|

| X Axis | Y Axis | Z Axis | |||

| Vertical Machining Center | Tongtai TMV-760A | 760mm | 450mm | 530mm | 1 |

| Vertical Machining Center | Tongtai TMV-850A | 850mm | 500mm | 530mm | 6 |

| Vertical Machining Center | Tongtai TMV-1100A | 1100mm | 530mm | 530mm | 4 |

| Vertical Machining Center | Champmill e-1100 | 1100mm | 610mm | 610mm | 3 |

| Vertical Machining Center | KAFO VMC-106 | 1020mm | 600mm | 635mm | 7 |

| Vertical Machining Center | KAFO VMC-137 | 1300mm | 700mm | 700mm | 1 |

| Horizontal Machining Center | KAFO HMC-630 | 1100mm | 825mm | 885mm | 1 |

| Horizontal Machining Center | DMG MORI NHX-4000 | 560mm | 560mm | 660mm | 1 |

| Horizontal Machining Center | DMG MORI NHX-6300 | 1050mm | 900mm | 1030mm | 4 |

| CNC Vertical Turning Center | Tongtai TVL-6DA | 760mm | - | 385mm | 2 |

| CNC Vertical Turning Center | Tongtai TVL-40 | 390mm | - | 285mm | 6 |

| CNC Vertical Turning Center | Victor Taichung VTURN-V760 | 780mm | - | 380mm | 1 |

| CNC Horizontal Turning Center | Victor Taichung Vturn-26 | 360mm | - | 600mm | 2 |

| CNC Horizontal Turning Center | Tatung OKUMA L400-E | 390mm | - | 520mm | 4 |

| 5-Axis Machining Center | Champmill C50-5A A-Axis Travel +30˚~-120˚ C-Axis Travel 60˚(Continuous) |

810mm | 700mm | 610mm | 1 |

| 5-Axis Machining Center | FFG U-600P A-Axis Rotation+110°~-90° C-Axis Rotation 360° |

460mm | 620mm | 400mm | 1 |

| 5-Axis Machining Center | Quaser UX600 | 885mm | 800mm | 500mm | 1 |

-

Vertical Machining Center:

Products of machining range under length of 1300mm and width of 700mm. -

Horizontal Machining Center:

Products of machining range under length of 1050mm and width of 900mm. -

Vertical Turning Center:

Products of machining range under diameter of 780mm. -

Horizontal Center:

Products of machining range under diameter of 390mm.

The distance between each aperture could be controlled under 0.01mm (special request), or under 0.02mm (normal request).

| Equipment | Spec | Q’ty |

|---|---|---|

| Ultrasonic Cleaning Machine | - | 2 |

| High Pressure Water Jet Cutter | - | 1 |

| Equipment | Spec | Q’ty |

|---|---|---|

| Automatic Welding Equipment | - | 1 |

| Equipment | Description | Q’ty |

|---|---|---|

| Liquid Coating Line | Coating, Drying | 1 |

| Equipment | Description | Q’ty |

|---|---|---|

| Liquid Leak Detection Machine | - | 1 |

| Gas Leak Detection Machine | - | 1 |