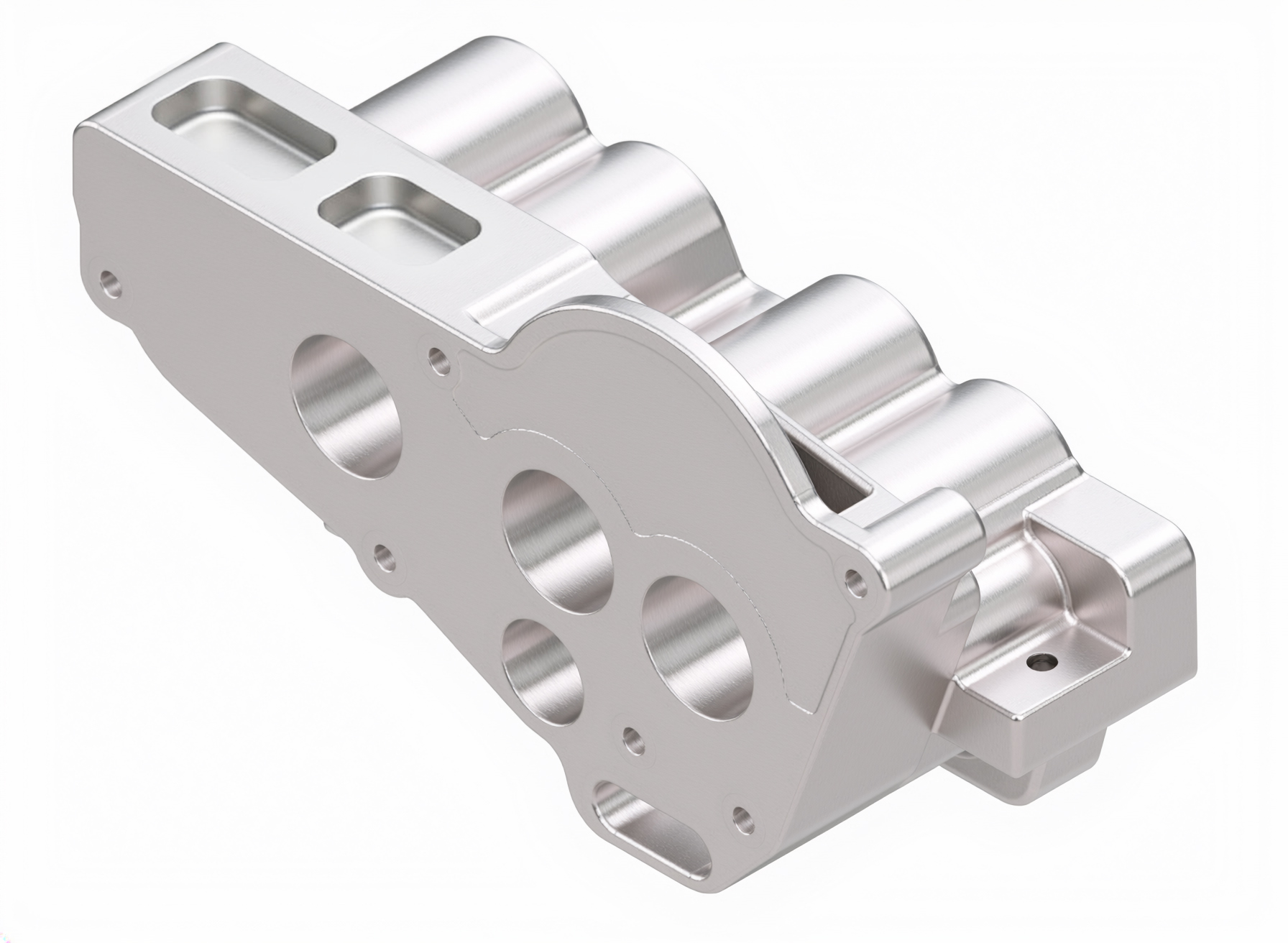

The transmission solenoid valve body features precision-machined internal cavities and port structures that control gear shifting, serving as a critical component in automatic transmission systems.

This valve body features complex internal cavities and flow path configurations, requiring high-precision multi-axis milling. The design demands strict relative positional accuracy between all ports, which challenges the positioning precision and process stability of machining equipment.

Manufacturing requires precision machining to control dimensional tolerances, along with drilling and tapping for assembly interfaces. Some internal features may require special tooling or multi-stage machining strategies, requiring comprehensive CNC machining capabilities and process planning expertise. The quality of the valve body's sealing and mating surfaces directly impacts the transmission's operational stability and service life.

Aluminum Alloy

View More...

View More...

Material Property Testing

Statistical Process Control

View More...

The product is made of cast aluminum alloy, balancing lightweight design with excellent machinability. It is suitable for milling complex shapes while providing sufficient mechanical strength, excellent heat dissipation, and corrosion resistance.

The mass production of this product demonstrates WKPT's technical capabilities in complex cavity machining, high-precision bore placement, and sealing surface quality control. If your product design involves complex structures, strict geometric tolerances, or requires balancing precision machining with mass production stability, we invite you to discuss your technical requirements and collaboration opportunities.