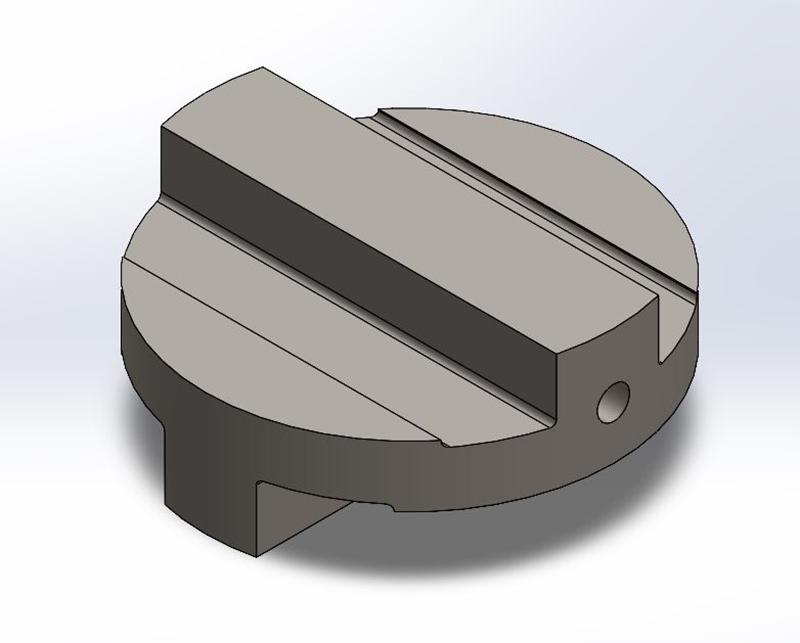

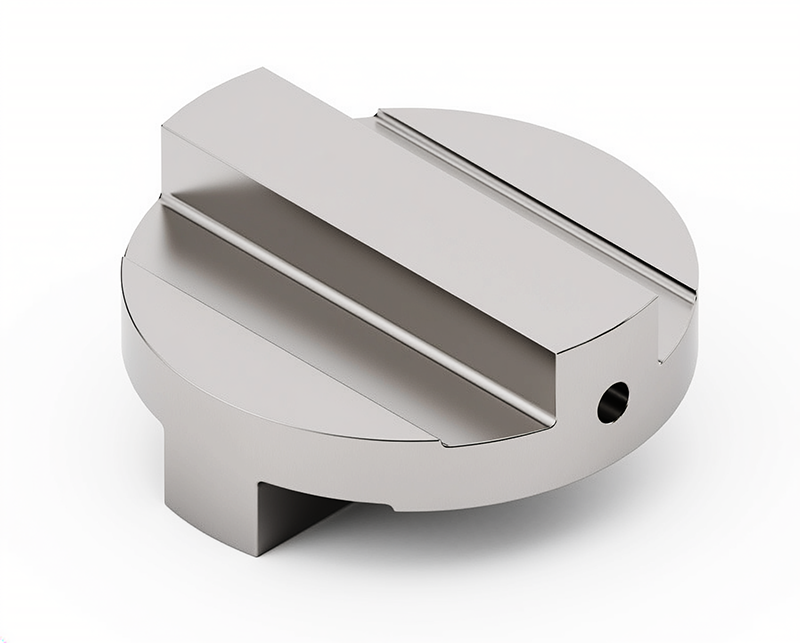

European-style hydraulic fittings serve as connection interfaces in hydraulic systems, ensuring reliable flow of high-pressure hydraulic fluid. Widely used in machine tools, industrial machinery, and agricultural equipment requiring precise hydraulic control.

The manufacturing challenge of hydraulic connectors lies in maintaining dimensional accuracy and sealing reliability throughout mass production. This product presents three major process challenges:

First, turning accuracy for eccentric geometric features. The main body and radial offset section must be machined in a single setup to eliminate runout caused by re-fixturing. This demands both machine rigidity and sophisticated toolpath programming.

Second, control of multiple geometric tolerances. From threaded sections to sealing surfaces, each mating interface requires strict positional and perpendicularity tolerances, necessitating precision measurement equipment and real-time process monitoring.

Third, dimensional stability after heat treatment. When medium carbon steel undergoes quenching and tempering to achieve specified hardness, critical dimensions are susceptible to distortion. This requires either machining allowances for distortion compensation or post-heat-treatment finishing operations.

Our turn-mill machining capabilities enable complex geometry production. Combined with SPC process control and long-standing collaboration with heat treatment partners, we consistently deliver these high-precision hydraulic components.

Variable Displacement Hydraulic Equipment/Piston-Type Hydraulic Machinery/Hydraulic Power Systems

Industrial hydraulic systems, industrial hydraulic pumps, hydraulic cylinders, piston pumps, piston motors, radial piston motors, radial piston hydraulic motors, bent axis piston motors, swash plate hydraulic pumps, swash plate axial piston pumps, hydraulic piston pumps, hydraulic piston motors, hydraulic pumps, hydraulic motors, hydraulic engines, hydraulic axial piston pumps, hydraulic axial piston motors, hydraulic valves, hydraulic drive systems, hydraulic variable piston pumps, axial piston pumps, axial piston motors, axial piston hydraulic pumps, axial piston hydraulic motors, axial piston variable pumps, electric pistons, variable speed hydraulic motors, variable piston pumps, variable motors, variable hydraulic pumps, variable hydraulic motors, variable axial piston pumps

View More...

View More...

Material Property Testing

Statistical Process Control

View More...