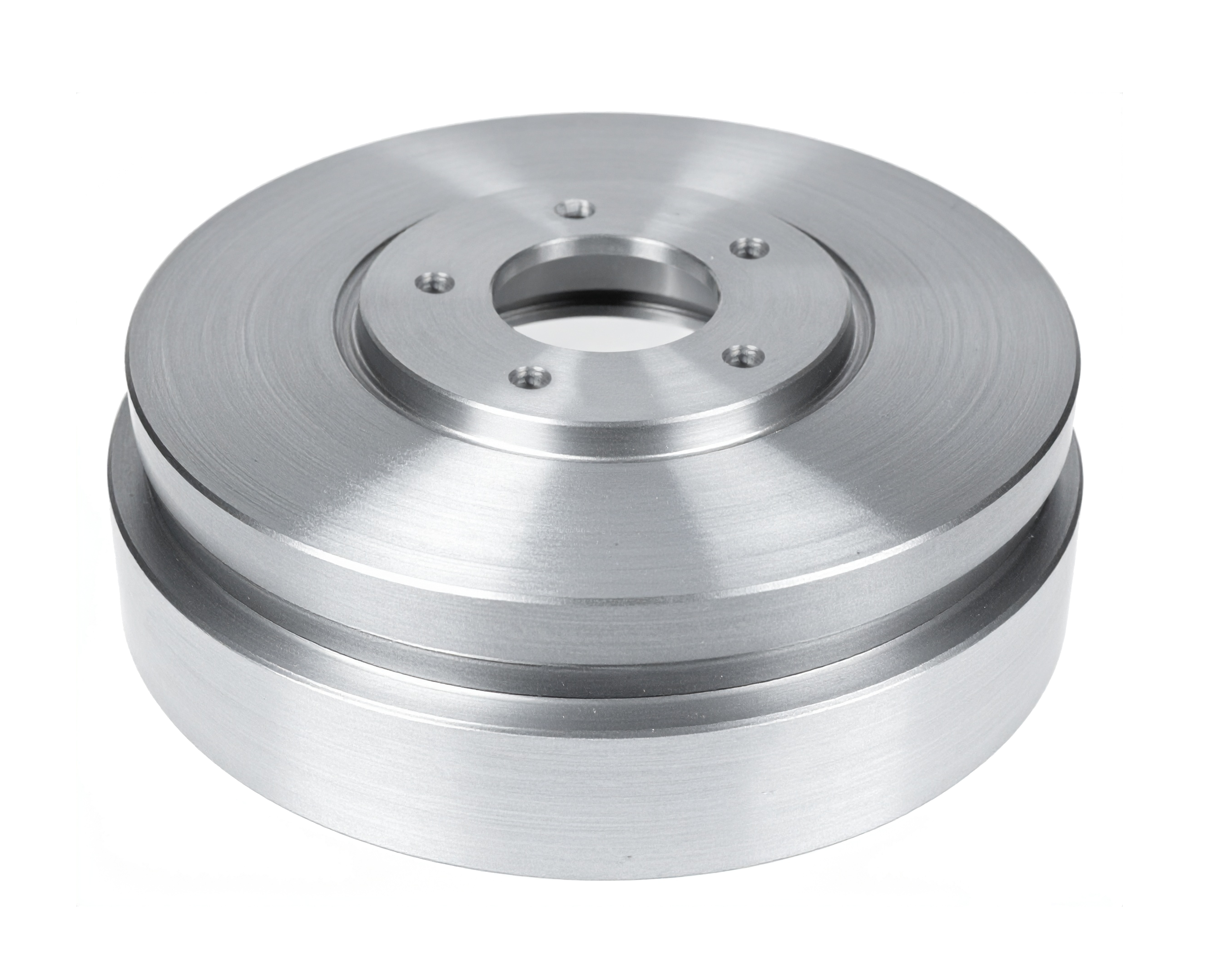

Brake spacer rings are manufactured from premium ductile cast iron, specifically engineered for forklift brake system environments.

The ductile cast iron material provides exceptional wear resistance and vibration damping properties, ensuring reliable brake system operation.

The brake spacer ring is a precision component in forklift brake systems, providing precise gap control to ensure proper clearance between brake pads and brake drums, preventing friction while promoting heat dissipation and maintaining braking performance. Its functions include controlling brake clearance, promoting heat dissipation, reducing noise, and ensuring brake responsiveness. The working principle operates through precision thickness control, providing appropriate movement space for brake pads and ensuring uniform contact with brake discs.

Our spacer rings utilize casting processes to ensure precise control of thickness and concentricity. Subsequently, they undergo CNC turning operations to achieve required surface finish and tolerance specifications. To enhance durability, products receive surface treatment to increase wear resistance and corrosion protection. Finally, we perform strict dimensional inspection to ensure installation precision, meeting industrial environment requirements.

AGV Automated Guided Vehicles, Forklifts, Lift tables, Stand-up forklifts, Self-propelled forklifts, Pallet trucks, Hydraulic trucks, Hydraulic pallet trucks, Hydraulic hand trucks, Warehouse equipment, Aerial work platforms, Aerial lifts, Stackers, Electric pallet trucks, Electric hydraulic trucks, Electric forklifts, Roll cages

View More...

While our ductile cast iron brake spacer rings excel with their superior wear resistance, vibration damping, and impact resistance—perfectly suited for demanding material handling applications—our manufacturing capabilities extend far beyond this single offering. We are a leading brake system component supplier, capable of producing various braking components using diverse materials tailored to your specific requirements.

Our product line encompasses:

Aluminum Alloy: Ideal for applications requiring lightweight construction and superior heat dissipation, such as high-frequency braking systems, to reduce inertia and improve heat dissipation efficiency.

Stainless Steel: The industry's preferred choice for marine, chemical, or marine environments with high requirements for corrosion resistance or extreme temperatures.

Carbon Steel: The cost-effective choice for heavy-duty brake systems, pursuing high strength and durability.

Each material is selected for its unique properties to ensure optimal performance under various operating conditions. From precision gap control to strict tolerance specifications, our brake components are manufactured using state-of-the-art casting and machining technologies.

Choose us as your partner, and you'll gain a comprehensive braking solution collaborator, providing reliable, high-quality, and customized solutions for your projects.