Industry 4.0 & Smart Manufacturing Solutions

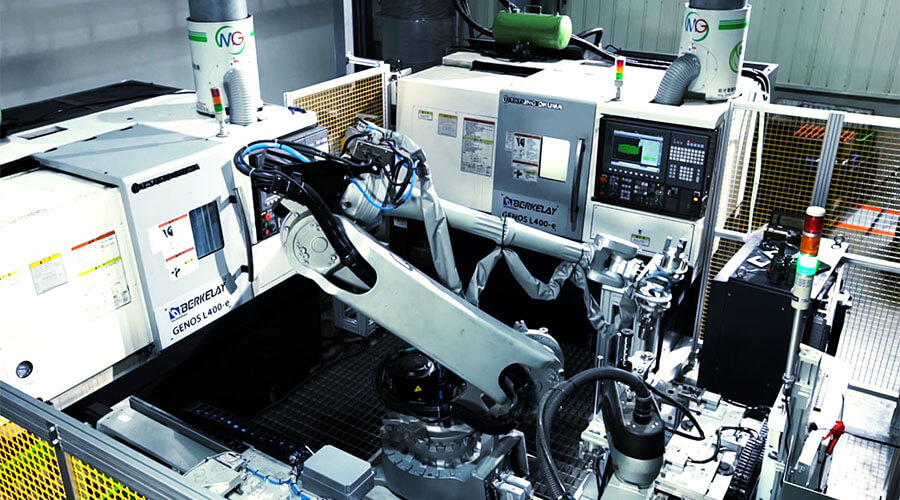

WKPT was a traditional manufacturer in its early days. As industrial technology advances, we have started a digital revolution in traditional industry. At an early stage, we have installed a complete ERP (Enterprise Resource Planning) and SFT (Shop Floor Tracking) system, etc. In the middle stage of the digital revolution, we have started collecting machine data from 20x CNC machines, PLC (Programmable Logic Controller) of the working platform and robotic arm, and developing Industrial IoT on site.

-

Start

from 20x CNC machines, systematically collecting data from machines then developing industrial

IoT on site.

Start

from 20x CNC machines, systematically collecting data from machines then developing industrial

IoT on site.

IoT of

PLC and Robotic Arm

IoT of

PLC and Robotic Arm

-

Digital Optimization and Data Analysis

After machine automation, we have invested in a series of digital optimization works, such as big data analysis, vertical and horizontal integration of supply chain, enterprise cloud and Internet safety, etc. Combining technology with the business model and keeping upgrades in operation, production, and customer experience, WKPT has become a modern metalworking manufacturer with smart production and data analysis skills.

Combine

technology with business models and keep upgrading in operation, production, and customer

experience.

Combine

technology with business models and keep upgrading in operation, production, and customer

experience.

-

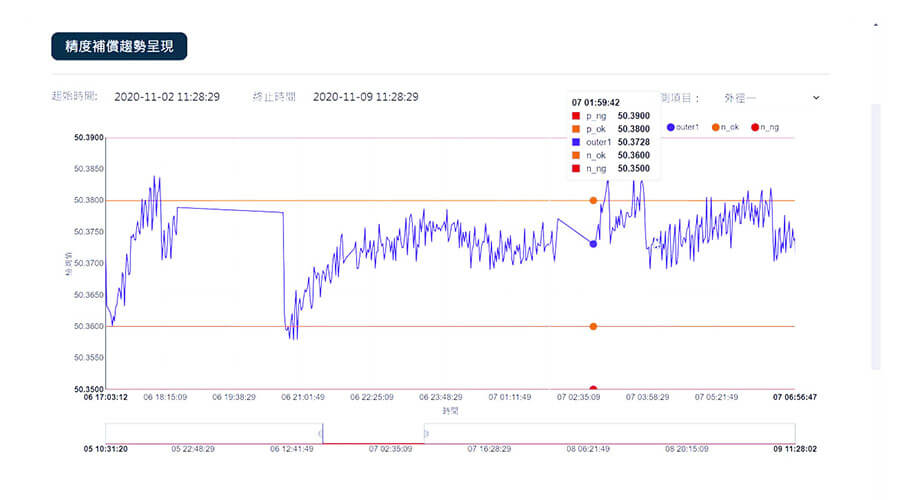

Smart Production Management System for Automotive Parts

At this late stage, we have imported a “smart production management system for automotive parts”, including manufacturing production management, device connection, and information visualization, auto accuracy compensation IoT security, etc. Data exported from machines will be added into PLM (Production Lifecycle Management), APS (Advanced Planning and Scheduling), MRP (Materials Requirement Planning), MES (Manufacturing Execution System), and power management. We also integrate this information into the BI Dashboard for decision-making in production control.

Auto

compensation feature will give feedback to the machine based on the automatic measuring results.

Auto

compensation feature will give feedback to the machine based on the automatic measuring results.

-

Factory Utilization Rate Increase

After investing in smart manufacturing, in high-mix low-volume mode, the machine utilization rate is from 55% to 78%, and the high-end production yields from 94% to 98%, which proves the utilization rate is successfully improved. We also keep device connection stable through IoT, improve production efficiency, and simplify management to raise the smart manufacturing level of WKPT.

Production

yield lifted from 94% to 98% after smart manufacturing.

Production

yield lifted from 94% to 98% after smart manufacturing.

-

AI Visionary Detection Polishing System

WKPT recently revealed the project results of the Ministry of Economic Affairs' "Digital Transformation of Metal Products and Supply Chain Upgrading Plan”, promoting high-value products and transformation of business models through new technologies such as artificial intelligence, big data, and cloud platforms.

Based on AI visual inspection technology, WKPT built an intelligent automated grinding system combined with robotic arms and applied it to the surface grinding of offshore wind turbine brakes. The grinding coverage achieved over 95% successfully. This project realizes the product application of the traditional manufacturing industry crosses the green energy industry, and enhances the added value of the metalworking industry. In addition, being aware of the importance of data sharing and collaboration in the company, WKPT imported a cloud-based platform for PLM and information flow. All project members from various departments have benefited from better communication and work efficiency. WKPT uses AI and cloud operations to promote high-value products and business model transformation and improve its competitiveness internationally。

Intelligent manufacturing introduces an AI visual recognition grinding system