Compared to machining from solid, our gravity casting solution significantly reduces material waste and cycle times, lowering overall costs while offering superior vibration damping properties.

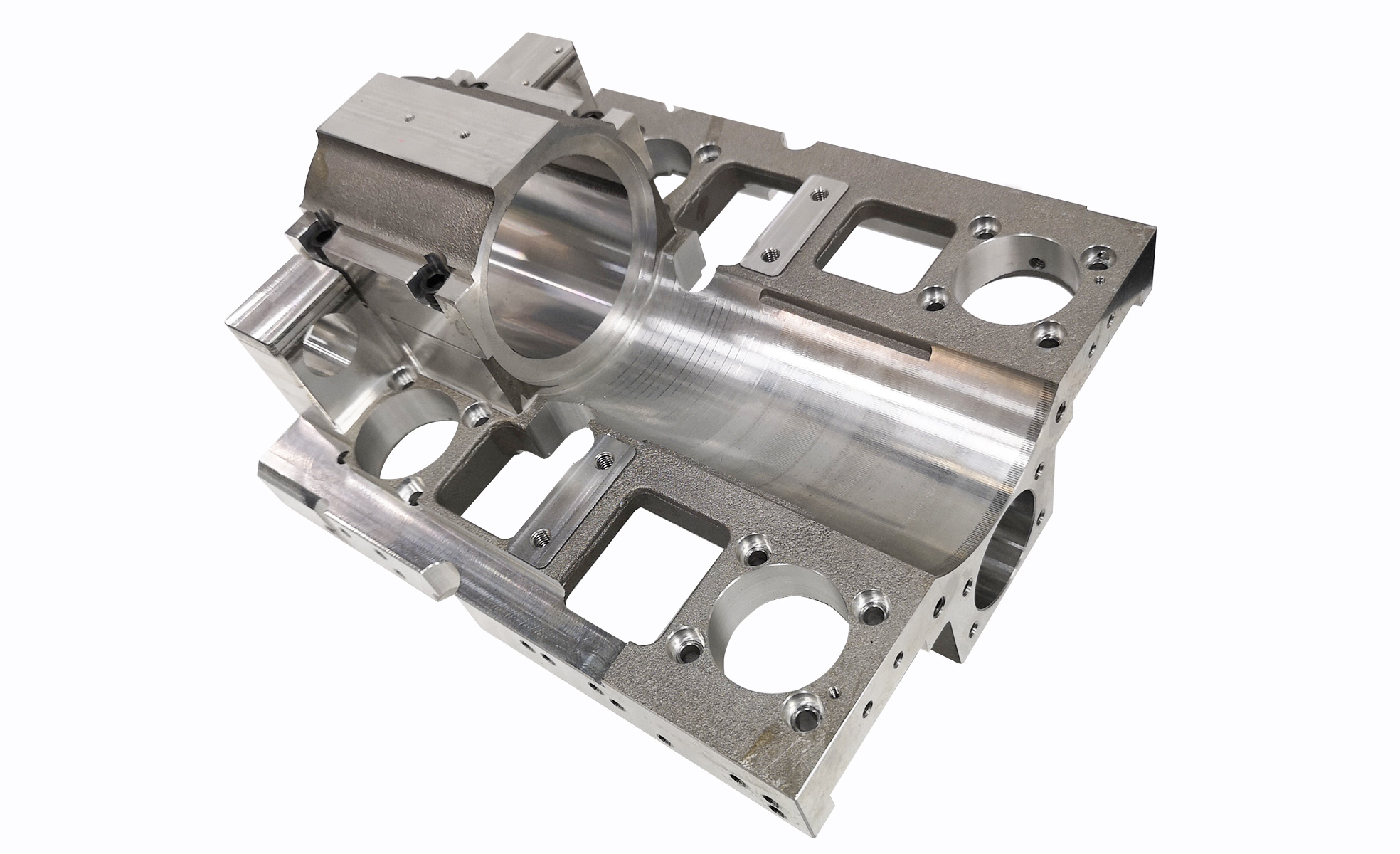

We utilize aluminum gravity casting to produce the main structural shapes. Gravity cast workpieces offer stable quality, high dimensional accuracy, and low surface roughness, significantly reducing subsequent machining requirements. The spindle housing for PCB drilling machines demands strict dimensional precision: tolerances within 10µm, form tolerances within 15µm, and surface roughness (Ra) under 1.6. We accept custom specifications and deliver fully assembled upper and lower housing units.

Applications

PCB Drilling Machines, Electronic Manufacturing Equipment, High-Speed Spindle Systems

Process

Aluminum gravity casting ensures high vibration damping and dense microstructure. Combined with precision CNC machining, we achieve tolerances within 10µm and surface finishes of Ra 1.6.

Material

Gravity Cast Aluminum Alloy (AC4C / A356 Equivalent)

QC Info

CMM (Coordinate Measuring Machine) Inspection, 3D Dimensional Verification, Pore-free Inspection.

Your High-End Aluminum Gravity Casting & Precision Machining Partner

We specialize in manufacturing aluminum gravity casting components for high-speed precision equipment. This process yields dense, low-porosity castings with excellent vibration damping properties—crucial for suppressing micro-vibrations during high-speed spindle operations. We offer a one-stop solution integrating mold development, casting, and precision CNC machining, ensuring micrometer-level (µm) accuracy while significantly reducing material waste and overall production costs.