Precision Valve Body Machining | Leak Testing Component Manufacturing

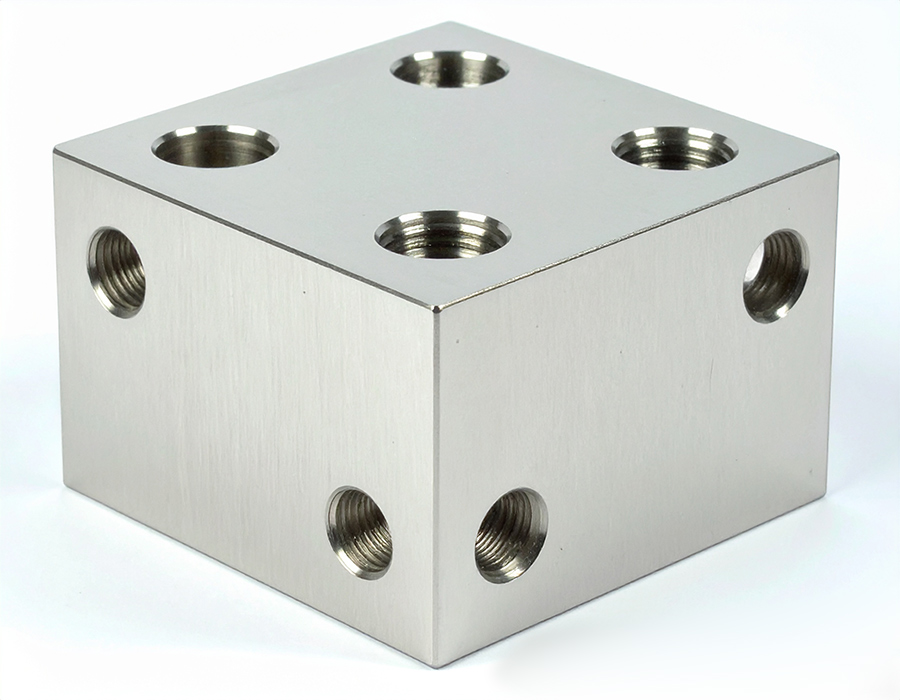

Precision valve bodies are manufactured from premium aluminum alloy, specifically engineered for precision testing equipment environments.

The aluminum alloy material provides exceptional machinability and lightweight properties, ensuring precise operation of gas flow control systems.

The valve body is positioned at the core of the leak testing instrument's gas flow control system, serving as the central hub for gas flow direction control throughout the entire testing system. Its functions include precise control of test gas flow paths, directing gas intake, testing, and exhaust processes, providing multiple sealing structures, and modular mounting interfaces. The working principle operates through sequential control of multiple solenoid valve switching, directing gas flow through precisely machined internal gas passages.

Product Applications

Precision Testing Equipment, Industrial Test Equipment

Gas leak testing, Automated leak testing, Helium leak testing, Hydrogen leak testing, Leak detection, Leak detectors, Pressure leak testing, Medical device leak testing, Package leak testing, Pressure leak testing, Vacuum leak testing, Valve leak testing

Gas leak testing, Automated leak testing, Helium leak testing, Hydrogen leak testing, Leak detection, Leak detectors, Pressure leak testing, Medical device leak testing, Package leak testing, Pressure leak testing, Vacuum leak testing, Valve leak testing

Material

Aluminum Alloy

View more...

View more...

Manufacturing Processes

Milling, Drilling, Tapping

View more...

View more...

Quality Inspection

Product Dimensional Measurement

Material Property Testing

Statistical Process Control

View more...

Material Property Testing

Statistical Process Control

View more...

Beyond Aluminum Alloy: Your One-Stop Precision Testing Equipment Parts Supply Partner

While our aluminum alloy testing valve bodies excel with their superior machinability, lightweight characteristics, and precision gas passage manufacturing capabilities—perfectly suited for demanding precision testing applications—our manufacturing capabilities extend far beyond this single offering. We are a leading precision testing equipment parts supplier, capable of producing various testing components using diverse materials tailored to your specific requirements.

Our product line encompasses:

Stainless Steel: Ideal for applications requiring extremely high corrosion resistance, such as chemical gas testing systems, to resist specialized gas corrosion while pursuing higher strength requirements.

Copper Alloys: The industry's preferred choice for applications requiring excellent electrical conductivity and precision sensing, particularly suitable for electronic testing applications.

Carbon Steel: The professional choice for heavy-duty testing equipment, pursuing high strength and cost-effectiveness.

Each material is selected for its unique properties to ensure optimal performance under various operating conditions. From complex internal gas passage designs to precision multiple sealing structures, our testing equipment components are manufactured using state-of-the-art CNC machining technology.

Choose us as your partner, and you'll gain a comprehensive precision testing solution collaborator, providing reliable, high-quality, and customized solutions for your projects.