Metal Types and Material Carbon Steel: From Metallurgy Engineering to Diverse Applications

The birth of metal materials originates from iron ore buried deep underground. After collection and transportation to steel mills, iron ore begins its smelting journey. In the blast furnace—the cradle of metals—coke plays a dual role: providing high-temperature heat while acting as a reducing agent to react with oxides in the iron ore. Fluxes like limestone help adjust slag viscosity, effectively separating impurities. This chemical reaction ultimately forms liquid pig iron at the bottom of the blast furnace, with carbon content as high as 3-5%, resulting in a hard but relatively brittle material.

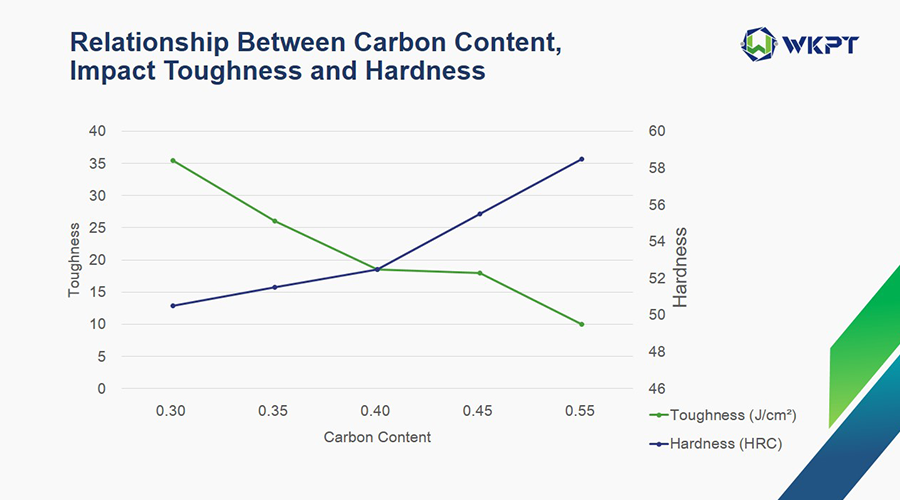

Next, the pig iron transfers to a converter where, under oxygen refinement, it undergoes decarburization and impurity removal with precise carbon content control. This stage highlights carbon's core value—not only playing a crucial role in the blast furnace reduction process but also determining the final material's basic characteristics. Iron-carbon alloys with carbon content between 0.02-2% are defined as steel, exhibiting diverse properties as carbon content varies: low carbon steel demonstrates flexibility, medium carbon steel combines toughness with strength, and high carbon steel is characterized by its hardness.

After secondary refining, liquid steel solidifies into billets in continuous casting machines, establishing the foundation for subsequent precision processing. This series of smelting processes transforms natural minerals into diverse metal materials, becoming pillars of modern industrial civilization.

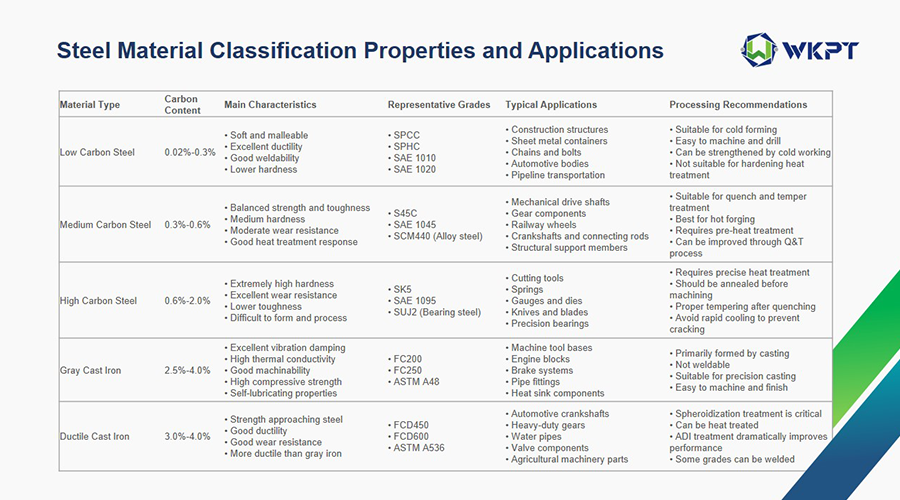

Carbon content serves as a measuring scale determining the identity and characteristics of iron-based materials. Based on carbon proportion, iron-carbon alloys are classified as follows:

Low carbon steel (0.02%-0.3%): Soft and easily processed, widely used in chains, bolts, and other everyday items.

Medium carbon steel (0.3%-0.6%): Achieves balance between strength and toughness, suitable for load-bearing components like gears and tracks.

High carbon steel (0.6%-2%): Characterized by extremely high hardness, primarily used for industrial molds.

Cast iron (exceeding 2%, typically 3%-5%): Possesses unique casting characteristics.

With advancements in metallurgical engineering, carbon content control has achieved extremely high precision. In modern steel production, high-carbon pig iron undergoes converter processing with precise oxygen blowing to achieve decarburization. From the Bessemer converter of the Industrial Revolution to today's pure oxygen converter, smelting technology continues to innovate, allowing steel materials to meet strict requirements for various engineering applications.

As the foundation of the steel industry, the history of pig iron can be traced back to ancient smelting techniques. In modern industrial systems, pig iron primarily plays the role of an intermediate product—its unique high-carbon characteristics (3%-5%) make it a necessary starting point for steel production, representing the essential first stage in the metallurgical transformation process.

Pig iron holds an irreplaceable position in contemporary industrial production, with over 70% of global crude steel output relying on pig iron as raw material. Beyond being a precursor to steel, some high-quality pig iron is also directly used in special casting production, utilizing its good fluidity and low shrinkage characteristics.

The stability of pig iron quality affects downstream steel quality, which is why modern blast furnace production particularly emphasizes composition control. By adjusting furnace charge proportions and smelting parameters, producers ensure high-quality pig iron that meets strict standards, laying the foundation for refining premium steel materials.

The cast iron family stands uniquely diverse in the materials world, with grey cast iron castings and ductile iron castings being the most representative types. Grey cast iron, with carbon present as flake graphite, gains vibration-absorbing capabilities, good thermal conductivity, and excellent cutting characteristics. This makes it an ideal choice for precision machine tool bases, with its stability ensuring high-precision machining quality.

The development of ductile iron castings is considered a breakthrough in casting technology. Through spheroidization treatment, sharp flake graphite transforms into rounded spherical forms, significantly reducing internal stress concentration in the material while enhancing strength and toughness. These advantages make ductile cast iron widely applicable in water pipes, automotive components, gears, and shafts. Particularly, ADI (Austempered Ductile Iron) ductile iron, treated with austempering, exhibits a composite structure of ferrite and austenite, demonstrating excellent fatigue strength and wear resistance, becoming the preferred material for high-stress components.

The diversity of the steel family stems from the unique characteristics brought by different carbon contents, providing targeted solutions for various industrial applications:

Low carbon steel demonstrates excellent plasticity in practical applications, making it the primary material for thin sheet stamping, screws, nuts, and building structures. Represented by SPCC (JIS standard), low carbon steel is particularly common in automobile bodies and household appliance casings.

Medium carbon steel plays a key role in engineering machinery, with S45C widely used in manufacturing gears and shaft components that need to withstand both impact and wear. In practice, this type of steel usually requires quenching and tempering to achieve an ideal balance of mechanical properties.

High carbon steel has an irreplaceable position in tool manufacturing. For example, SK5 (Japanese standard) is commonly used for making cutting tools and blades. After appropriate heat treatment, it can exhibit high hardness above HRC60 and excellent wear resistance, though design considerations must account for its relatively lower impact toughness.

Metal material selection forms the foundation of product design, influenced by three key factors.

Material properties determine product functionality and performance—high carbon steel's strength and hardness make it suitable for industrial molds; ductile iron's pressure resistance makes it ideal for water pipes; cold-rolled steel products, with their thin and precise characteristics, are widely used in automobile bodies and home appliances; while cast iron with specific graphite structures provides the dimensional stability required for machine tools.

Material processability affects manufacturing methods and design feasibility—complex-shaped parts often select materials with good casting properties; high-sulfur steels' excellent machinability makes them suitable for precision processing; while mechanical low carbon steel is favored for its ease of forging, cutting, and welding.

Material treatment technologies expand design possibilities—austempering and quenching/tempering can alter the microstructure of ductile cast iron, optimizing its mechanical properties; phosphate treatment on steel plates enhances corrosion resistance; while special internal and external coatings on ductile iron pipes significantly extend their service life. Product development must consider the interaction of material characteristic factors to manufacture quality products combining functionality, durability, and economy.

As your partner in metal component manufacturing, World Known Precision Industry deeply understands the critical impact of selecting appropriate materials and precision machining on product performance. We possess comprehensive manufacturing capabilities from material forming and mechanical processing to surface treatment, providing customized, high-precision metal parts solutions for various industrial applications. Whether you're from the energy industry, agricultural equipment industry, or general machinery industry, we can meet your specific product requirements. With rich industry experience and professional equipment, we have established long-term partnerships with many renowned enterprises, with our product quality highly recognized. Let us work together to create high-quality metal products meeting international standards and enhance your product's market competitiveness.