Advanced Manufacturing: Scale, Speed, and Quality

-

Discover how machine vision and AI are revolutionizing quality control in metal manufacturing. Learn about the limitations of manual inspection, the benefits of smart technologies, and how WKPT successfully implemented AI-powered visual inspection to improve efficiency and product yield.

-

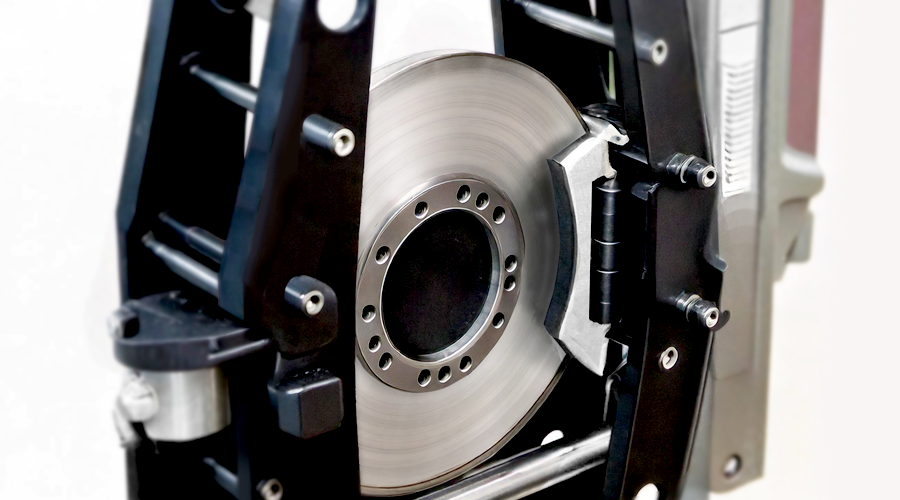

High-quality industrial brake system components are the key to maintaining safe operation of equipment. Especially in heavy industrial fields such as port cranes and construction machinery, the reliability of the brake system significantly affects operational safety and efficiency.

-

WKPT discovered abnormal tool vibration during a machining process and immediately initiated a root cause analysis. The team employed the 4M1E method to comprehensively investigate the causes of the problem. This serves as one of many root cause analysis examples in the manufacturing sector. Based on the investigation results, the company designed and implemented a complete solution:

-

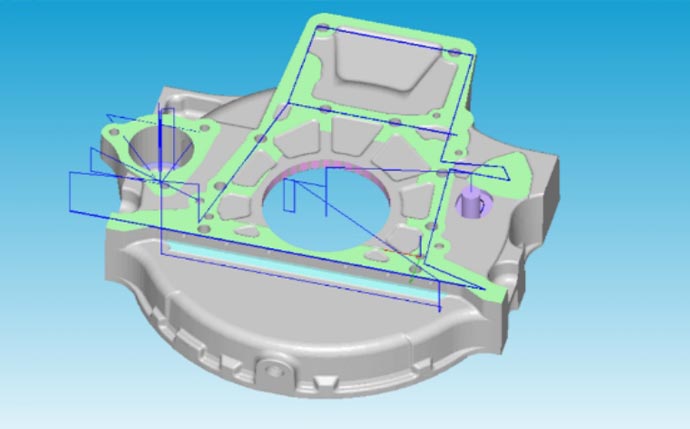

Process optimization represents a cutting-edge approach to sustainable manufacturing, utilizing advanced cutting force mechanics simulations and smart manufacturing technologies to minimize environmental impact. WKPT's innovative "Production Process Upgrade with Smart Manufacturing for Automotive Component" project employs sophisticated algorithms to analyze chip thickness, cutting force, spindle load, and tool load at each point along machining tool paths. Through precise feed rate adjustments and 3D simulation software, this technology optimizes machining programs to reduce unnecessary power consumption, protect equipment, and significantly lower carbon emissions while maintaining superior product quality and precision.

-

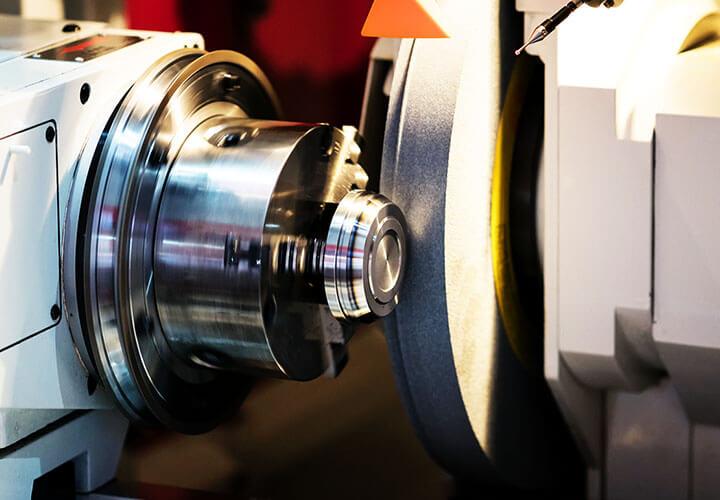

The precision quality of industrial products continuously improving, and the requirements of precision of parts manufacturing are also higher than before, which has reached the demand of micrometers (㎛).

-

Lathes play an important role in industry development, known as the mother of industry, and is the most important machinery in precision machining.

-

A robotic arm is an automatic control device that is similar to a human arm functioning and able to do various tasks. The main purpose of this automatic device is to complete the movements of the "wrist and hand". It can do the same movement correctly and repeatedly countless times, which will be a great help to improve the labor force and increase production efficiency.

-

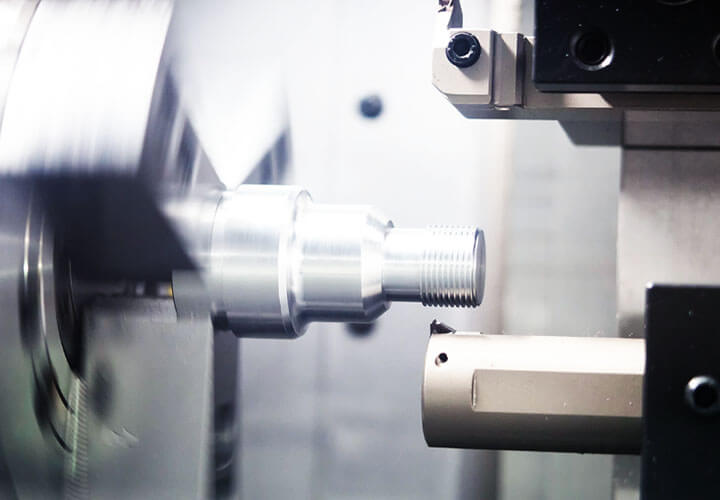

Online measurement technology represents the cornerstone of Industry 4.0 smart manufacturing, contributing to an estimated $14.2 trillion global economic impact by 2030 through enhanced production quality management and automated inspection processes. WKPT's groundbreaking smart manufacturing line for gearbox mandrels, established in 2019 as Taiwan's first domestic implementation, revolutionizes automotive parts production through integrated robotic arms and automated online measurement systems. This advanced technology precisely measures internal and external diameters of mandrels while synchronizing real-time data to computers integrated with Statistical Process Control (SPC) systems, generating comprehensive control charts for continuous process capability monitoring. The implementation has transformed quality assurance operations from requiring two daily personnel to fully unmanned operations, achieving zero defective production batches and providing reliable detection assistance throughout the production line for superior automotive component manufacturing.

-

Learn how WKPT's ISO 45001 certification ensures a safe and healthy workplace. We detail our comprehensive hazard prevention, risk management, and employee well-being initiatives.