EGR: the Solution for Reducing NOx Emission

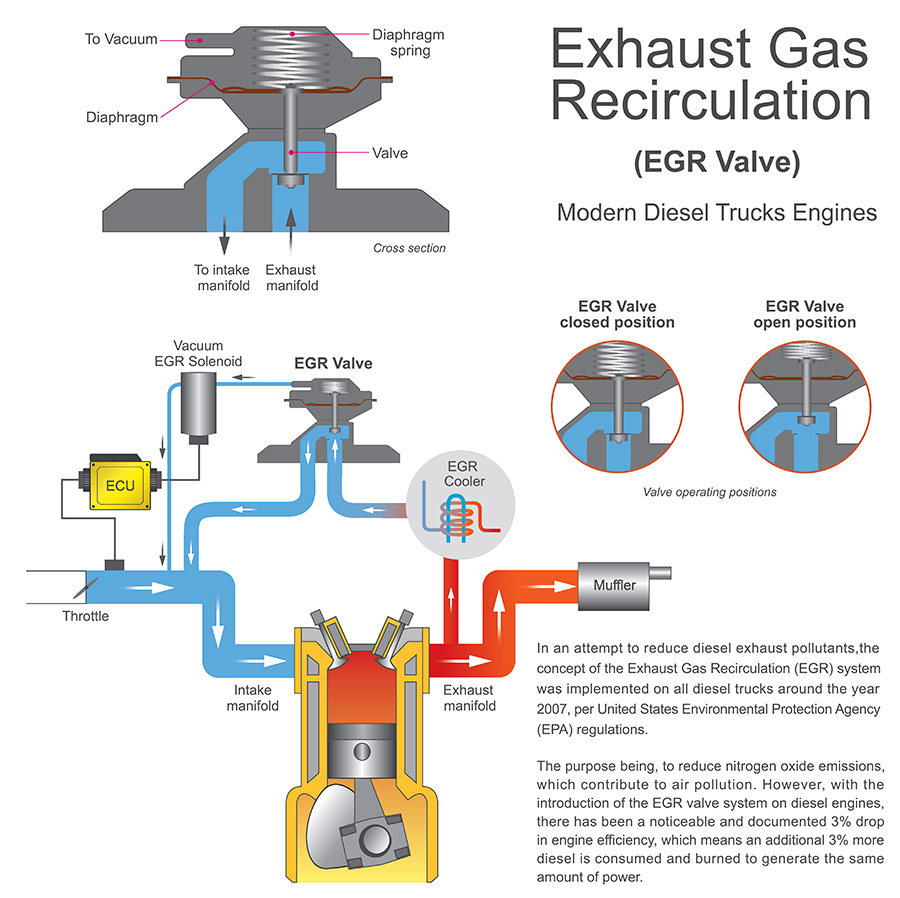

EGR stands for Exhaust Gas Recirculation. It is an emission control technology used in engines, which redirects a portion of exhaust gases back into the intake system. This can lower the combustion temperature of the engine, thereby reducing the emission of nitrogen oxides (NOx).

Nitrogen oxides are produced during the combustion of fuels, including exhaust emissions from automobiles, large vehicles, and non-road mobile machinery. If there are low concentrations of nitrogen oxides in the air, individuals may experience symptoms such as coughing, shortness of breath, fatigue, or nausea. Prolonged exposure to low concentrations of nitrogen oxides in the environment can lead to health hazards such as bronchitis and pulmonary edema. Therefore, environmental protection agencies worldwide legislate to regulate the emission of nitrogen oxides.

Currently, various countries have emission standards for non-road mobile machinery, which are listed below:

- European Union: (EU)2016/1628 Requirements relating to gaseous and particulate pollutant emission limits and type-approval for internal combustion engines for non-road mobile machinery

- United States: Regulations for Emissions from Nonroad Vehicles and Engines

- Japan: Act on Regulations for Emissions from Non-Road Vehicles

- Taiwan: Air Emission Standards of Mobile Source

- China: Limits and measurement methods for emissions from diesel fueled heavy-duty vehicles (CHINA VI)

For large vehicles such as commercial vehicles that use diesel engines, or non-road mobile machinery such as agricultural equipment, reducing nitrogen oxide emissions can be achieved through various methods such as modifying diesel engine designs, installing after treatment systems, and using low-sulfur fuels. Among all, Exhaust Gas Recirculation (EGR) is one of the methods used for emission reduction.

EGR systems are typically used in high-temperature applications, so they are often made of steel or cast iron materials. In addition, high-silicon molybdenum ductile iron, which combines the properties of high strength and high temperature resistance, is also suitable for making EGR systems.

Since EGR systems are used in vehicles and non-road mobile machinery, there are certain quality requirements for manufacturing. The relevant quality standards include:

ISO 9001 Quality Management System: Ensures stable and consistent product quality to meet customer expectations.

IATF 16949 Quality Management System: A general quality management system for the automotive industry, aimed at preventing defects, reducing variation and waste, and establishing trust between customers and suppliers.

Reducing nitrogen oxide emissions is an irreversible trend, and manufacturers of large vehicles and non-road mobile machinery continue to develop more environmentally friendly products. According to a survey report by Business Research Insights, the global EGR valve market had a scale of $840 million in 2021 and is expected to grow to $1.438 billion by 2031, with a compound annual growth rate of 5.52%. The effects of EGR application in different fields are as follows:

●Passenger vehicles: Reducing emissions and improving fuel efficiency.

●Commercial vehicles: Meeting emission regulations and providing optimal performance

●Tractors: Improving engine efficiency and reducing environmental impact.

As global environmental standards become increasingly stringent, EGR products that can reduce emissions and minimize environmental impact continue to generate strong demand in the commercial vehicle and tractor markets. WKPT has years of experience in manufacturing EGR components with the material of high-silicon molybdenum ductile iron, providing stable supply sources for international manufacturers. If you have EGR product requirements for commercial vehicles and agricultural machinery, contact us today to start the project.

Reference

Hannu Jääskeläinen, Magdi K. Khair, 2022. “Exhaust Gas Recirculation (2022)”, DieselNet, web page, viewed January 25, 2024, https://dieselnet.com/tech/engine_egr.php “EGR Valve Market (2023)”, Business Research Insights, webpage, viewed January 26, 2024, https://www.businessresearchinsights.com/market-reports/egr-valve-market-109962