Manufacturing Solutions for Transmission Housings for Automotive

With the global trend towards vehicle electrification and continuous improvement of internal combustion engines, transmission housing manufacturing technology faces unprecedented challenges and opportunities. As a critical component of the power transmission system, transmission housing must not only ensure excellent sealing and structural strength but also meet market demands for lightweight design and high performance. World Known Precision Industry offers comprehensive transmission housing manufacturing solutions---from material selection and process optimization to quality verification---helping customers maintain a competitive edge in the challenging automotive market through professional manufacturing technology and quality management capabilities.

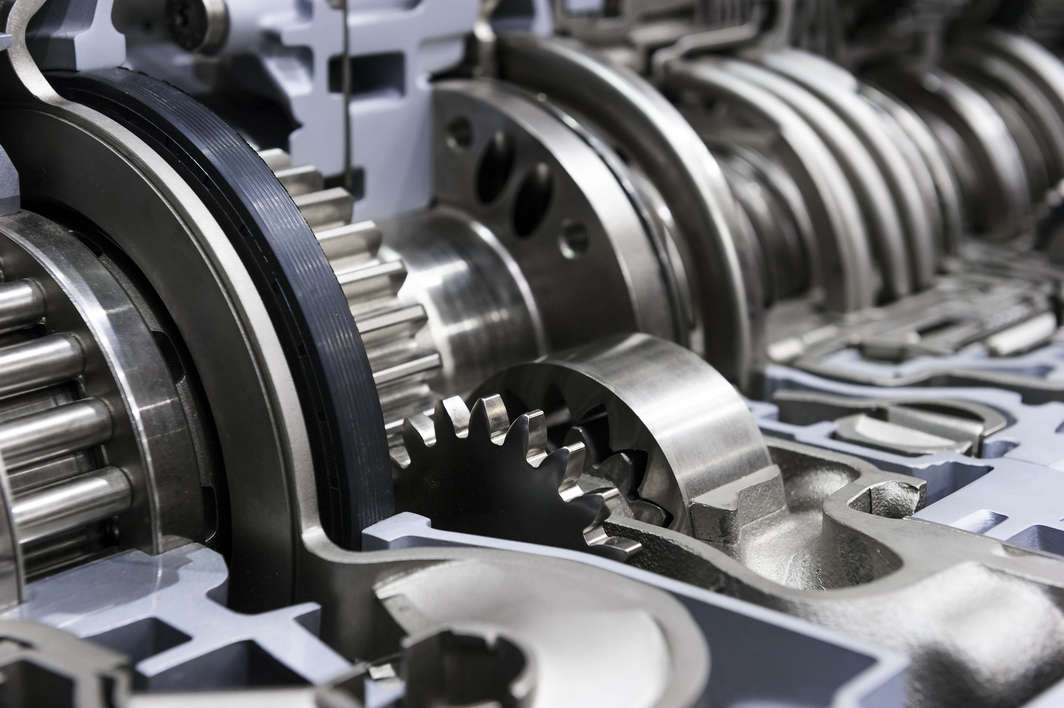

Transmission housing is an essential structural component that protects and supports the transmission system. Its primary functions include containing transmission fluid, protecting internal components from external contaminants, and maintaining precise alignment of gears, shafts, and bearings while managing operational stress.

Traditional internal combustion engine (ICE) transmission housings are designed to handle high torque fluctuations, mechanical friction heat, and complex oil circulation systems. They must integrate with the flywheel housing and clutch assembly while providing mounting points for various external components.

In contrast, electric vehicle (EV) transmission designs are simpler due to fewer gear ratios. They focus on weight reduction, integration with electric motors, and different thermal management requirements. Sealing requirements also differ to accommodate the high-speed operation of electric motors.

In the early development of the automotive industry, transmission housings were primarily manufactured from cast iron, offering good strength and durability but adding considerable weight that hindered overall vehicle lightweight design. As automotive lightweight trends advanced, aluminum alloys gradually became the mainstream choice for modern transmission housings.

Aluminum alloys offer multiple advantages for transmission housing applications:

1. Lighter weight---reducing weight by 40-50% compared to traditional cast iron, significantly improving fuel efficiency

2. Excellent heat dissipation---aluminum alloys have a thermal conductivity approximately three times that of cast iron, helping maintain optimal transmission operating temperatures

3. Good machinability---enabling more complex structural designs

Common aluminum alloys used in modern transmission housings include:

ADC12: Features excellent flowability and filling capability, suitable for complex thin-walled die-cast parts, and is one of the most widely used materials.

A380: Possesses good strength and wear resistance while offering excellent machinability.

AlSi10Mg: Features excellent weldability and corrosion resistance, commonly used for high-end transmission housings.

The manufacturing process of transmission housings requires rigorous process control to ensure product quality and reliability. Key manufacturing considerations include mold design precision, molten metal quality control, and die-casting parameter optimization. To ensure product quality, modern manufacturing technology integrates multiple advanced analysis methods.

Moldflow Analysis is an important predictive tool that simulates the entire die-casting process before manufacturing. Through simulation analysis, engineers can optimize the design of gating systems and predict and improve molten metal flow patterns. This technology can also predict the position and characteristics of weld lines, offering improvement solutions to reduce their impact on product strength. Additionally, Moldflow analysis can predict product deformation, helping engineers adjust mold design and cooling system configuration to reduce warping risks.

X-ray analysis technology is used for finished product inspection and effectively detects internal defects. This technology can precisely detect porosity distribution, identify internal cracks or inclusions. Simultaneously, X-ray analysis is used to verify wall thickness uniformity, ensuring compliance with design specifications. During the assembly phase, this technology can check whether the installation position and clearance of internal components are correct, ensuring product assembly quality.

The application of these advanced analysis methods significantly improves the manufacturing yield and product reliability of transmission housings while shortening development time.

Quality issues in transmission housing manufacturing primarily stem from three categories of manufacturing defects. First is porosity, which commonly occurs due to trapped air during die-casting, insufficient material drying, improper venting design, or material degradation from poor temperature control. These pores can lead to leakage or insufficient strength.

Second are issues caused by process-induced stress, including internal stress from uneven cooling, surface cracks from excessive ejection force, improper weld line positioning, and pressure-holding problems. These factors may cause product cracking or deformation during use.

The third category involves dimensional precision challenges, such as warping that affects overall assembly, insufficient flatness of sealing surfaces, bolt hole position accuracy deviations, and uneven wall thickness. These issues can affect product sealing performance and assembly quality.

To prevent these problems, manufacturers employ multiple control measures, including Moldflow analysis to optimize process parameters, X-ray inspection systems for quality control, continuous process parameter adjustment, and establishment of comprehensive quality control procedures. These preventive measures effectively reduce the occurrence of manufacturing defects, ensuring product quality.

When you choose to partner with World Known Precision Industry for transmission housing development, you'll experience comprehensive professional manufacturing services. In the early development stage, our engineering team utilizes advanced Moldflow analysis technology to help optimize your product design, identify potential manufacturing risks in advance, and provide concrete improvement solutions. Through this preventive analysis, potential issues in subsequent mass production can be effectively reduced, saving you valuable development time and costs.

During the manufacturing phase, your product will be handled by our experienced precision machining team. We possess precision machining equipment and comprehensive surface treatment capabilities to meet all precision requirements for your transmission housing. Combined with high-precision X-ray inspection systems, we provide in-depth product quality analysis---from wall thickness uniformity and internal defect detection to assembly clearance verification---ensuring every detail meets specifications.

World Known Precision Industry is your trusted technical partner. With professional analytical capabilities and precision machining technology, we can help you create high-quality transmission housing products and enhance your market competitiveness.

Learn more: Automotive Gearbox Housing Manufacturing Case