Precision Machining for High-Performance Metal Parts

Total

20

-

Wind energy component manufacturing represents a critical sector in global carbon neutrality efforts following the 2015 United Nations Climate Change Conference (COP 21) commitment to achieve zero emissions by 2050, driving economic growth and industrial transformation through renewable energy development. WKPT serves as Taiwan's exclusive supplier of wind turbine brake cylinders, providing comprehensive manufacturing solutions for wind power motor gearboxes, yaw brake systems, emergency brake systems, hydraulic systems, and brake components to Tier-1 supply chains and original equipment manufacturers. Our advanced engineering capabilities address the transition from onshore to offshore wind power applications, developing specialized low-temperature resistance ductile iron materials superior to EN-GJS-LT standards that maintain exceptional impact toughness in -20℃ environments, with ongoing development for -40℃ to -60℃ conditions. For offshore wind turbines operating in hypersaline and underwater environments including splash zones, intertidal zones, and underwater zones, WKPT's protective coating systems meet ISO 12944 C3M/C4H industry standards, ensuring 15-year durability against corrosion while maintaining ISO 9001 and IATF 16949 quality management through collaborative design and precision manufacturing solutions.

-

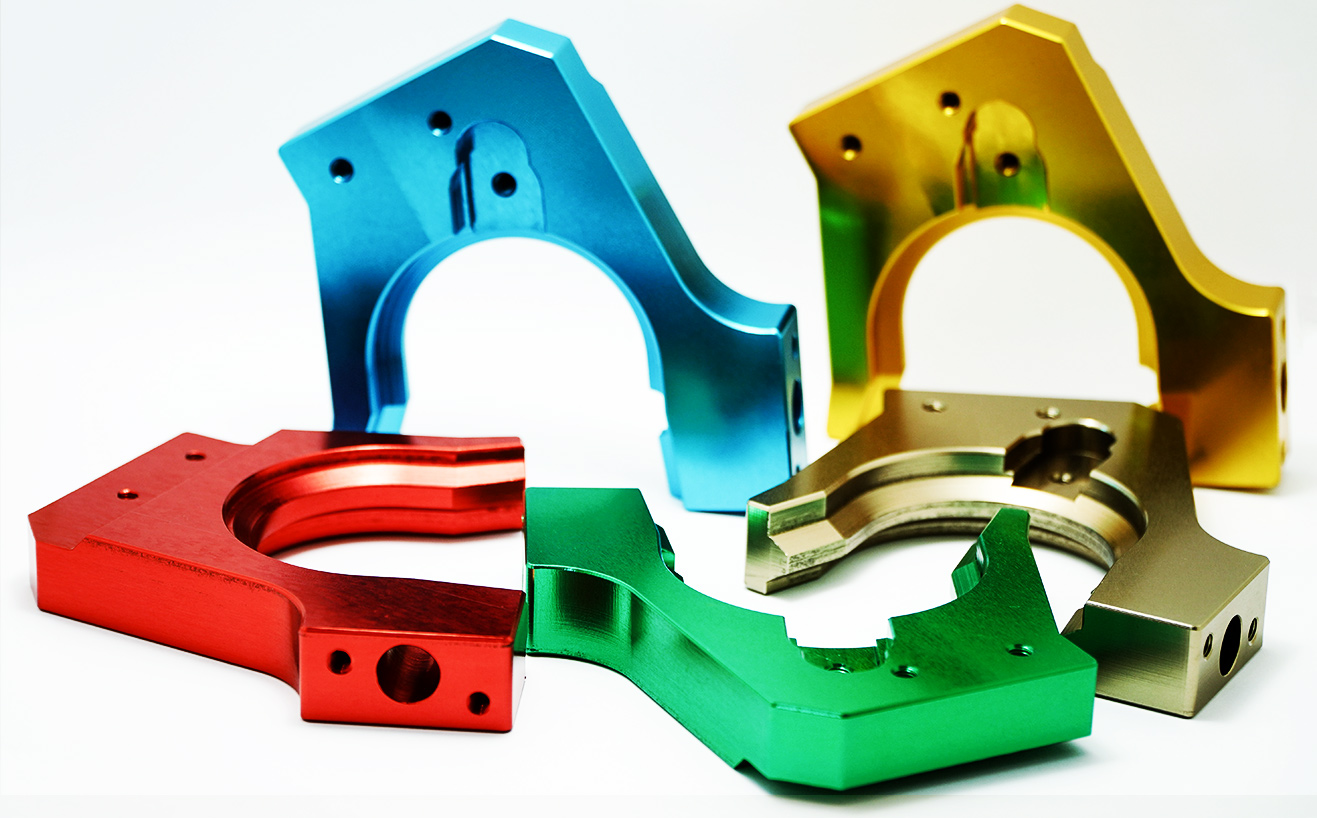

WKPT provides surface treatment services such as liquid coating, powder coating, electroplating, etc. on machined parts such as aluminum alloy, cast iron, stainless steel, and carbon steel. The surface treatment of aluminum alloy parts is mainly anodizing and hard anodizing.

-

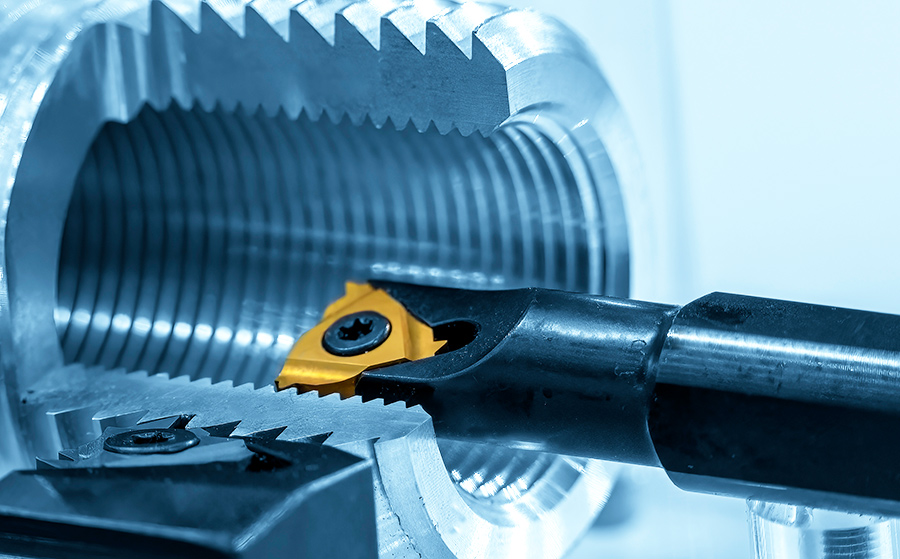

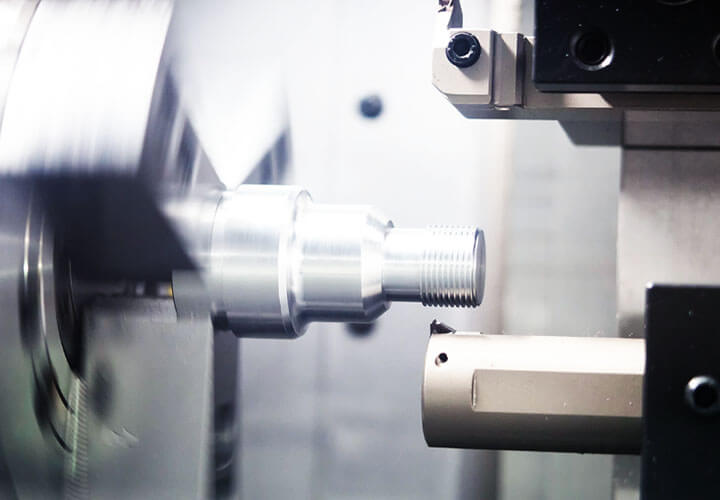

Thread machining services: thread turning, thread milling, and thread tapping. Thread turning involves cutting with shaping tools or thread tools on a rotating workpiece, suitable for precision manufacturing of internal and external threads in small quantities.

-

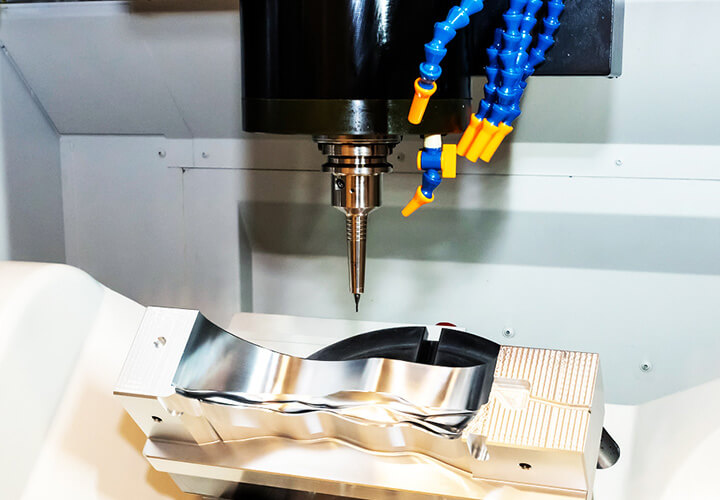

Discover WKPT's 5-axis CNC machining services for complex, high-precision parts. We specialize in multi-angle machining, customized production, and automated efficiency for demanding industries.

-

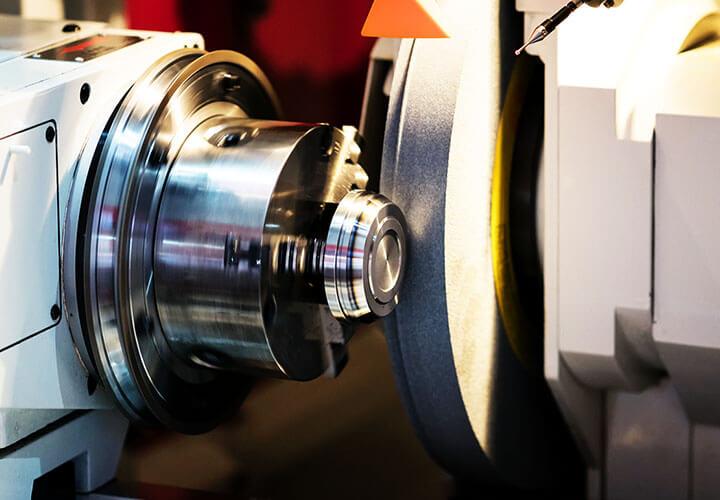

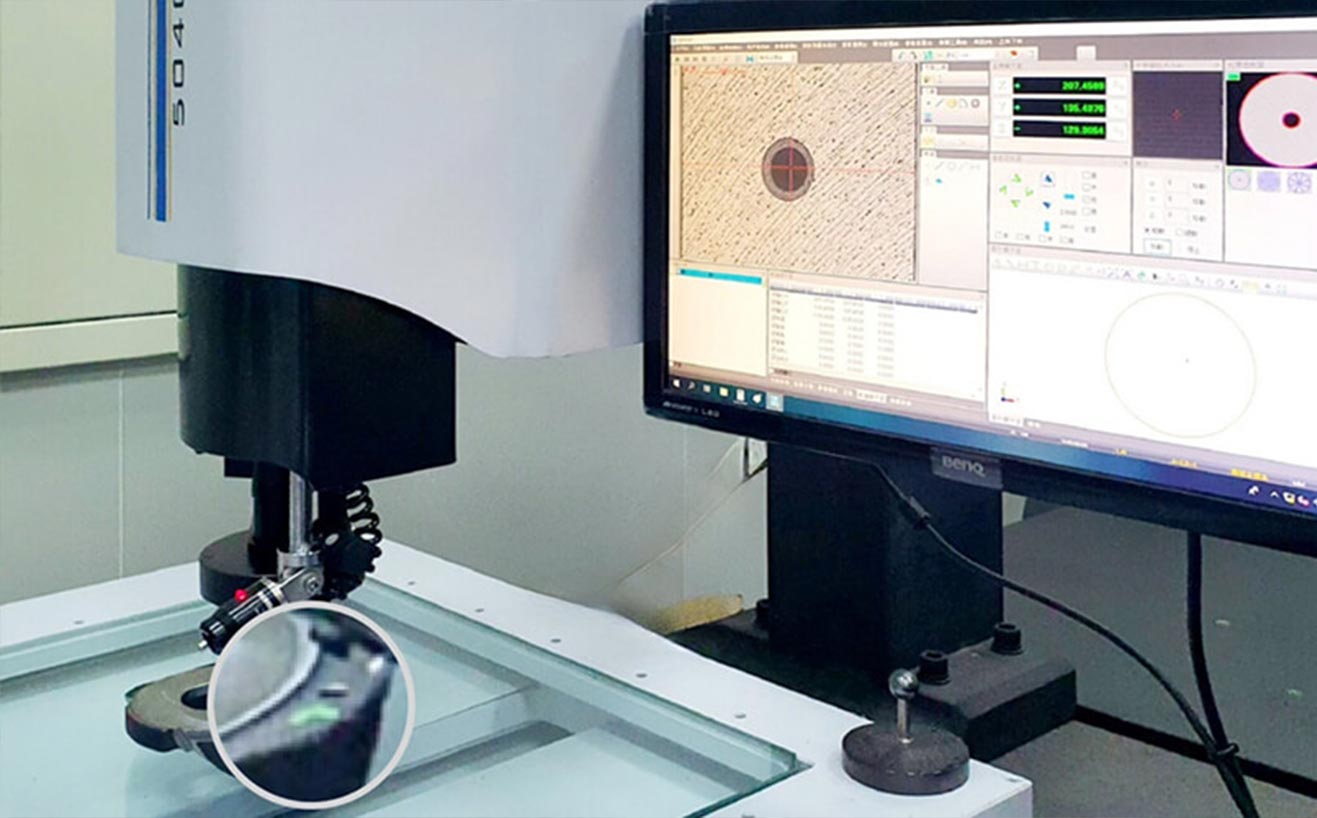

The precision quality of industrial products continuously improving, and the requirements of precision of parts manufacturing are also higher than before, which has reached the demand of micrometers (㎛).

-

Lathes play an important role in industry development, known as the mother of industry, and is the most important machinery in precision machining.

-

A milling machine is a device that fixes the workpiece on the main shaft of the machine tool and removes the material by the high-speed rotation of the tool.

-

Micro aperture measurement represents a critical challenge in precision machining where traditional measurement tools encounter limitations when dealing with tiny holes of 1mm diameter or less. WKPT employs advanced image measuring instruments that utilize non-contact optical measurement technology to overcome the probe limitations of conventional three-dimensional measuring instruments (CMM), enabling precise measurement of microscale apertures with exceptional geometric tolerance accuracy. This sophisticated measurement approach involves magnifying the target through optical systems to obtain precise dimensional data while offering programmable features for synchronized high-volume measurements and rapid results acquisition. While basic GO/NO GO pin gauges provide immediate aperture feedback for sorting applications, image measuring instruments deliver the precise dimensional data required for quality control in precision machining applications. WKPT's comprehensive measurement methodology selection ensures optimal inspection approaches for various workpiece dimensions and conditions, supporting precision quality standards that help customers achieve superior manufacturing results.

-

Aluminum alloy rust resistance and surface protection represent critical engineering considerations in modern industrial applications, where natural oxide films require enhancement through advanced anodizing processes to ensure long-term durability and performance. While aluminum alloys naturally generate protective oxide films when exposed to air, these naturally occurring layers may corrode over time in harsh environmental conditions, necessitating artificial anodizing treatments that create thicker, more robust protective films with enhanced surface hardness and corrosion resistance. WKPT specializes in hard anodizing processes for applications such as 6061T6 aluminum alloy casings used in medical testing equipment, employing precisely controlled temperature, voltage, and current density parameters to achieve 25µm thick protective layers with HV500 hardness that meet ISO10074 standards. This advanced surface treatment technology extends across multiple industries including aviation, aerospace, automotive, electronics, optics, and construction, providing lightweight, high-strength, acid-alkali-resistant components with superior wear resistance, enhanced conductivity, improved optical performance, and extended service life in extreme operating environments.