Hastelloy Hookup Components Manufacturing Solutions

Hastelloy Hookup Component Manufacturing Solutions

Hookup systems in industrial processes are responsible for distributing chemical liquids, ultrapure water, and gases from main supply lines to individual process equipment. Compared to primary piping, hookup systems operate closer to the process core and must withstand direct contact with highly corrosive chemicals such as hydrofluoric acid and sulfuric acid, while maintaining an ultra-high purity environment to prevent metallic ion leaching that could contaminate precision processes. These components must not only remain stable under high-temperature and high-pressure conditions but also possess weldability and machinability to meet the demands of complex piping layouts. With its exceptional corrosion resistance and ultra-low metallic ion leaching characteristics, Hastelloy has become the ideal material choice for semiconductor hookup systems.

HASTELLOY® alloy is a flagship trademark of Haynes International, and with over 75 years of development history, it has become a critical material for solving corrosion challenges in the chemical processing industry. For hookup systems, the value of Hastelloy lies in its precisely controlled chemical composition ratios, combined with systematic thermomechanical processing techniques and quality testing procedures, ensuring that every batch of products can achieve the consistent performance required by hookup systems.

The HASTELLOY® and HAYNES® alloy product lines are primarily divided into two major categories: Corrosion-resistant Alloys and High-temperature Alloys, capable of simultaneously addressing both the high-temperature processes and highly corrosive chemical challenges found in semiconductor hookup systems.

Hastelloy has become the preferred material for hookup systems primarily due to its three core characteristics:

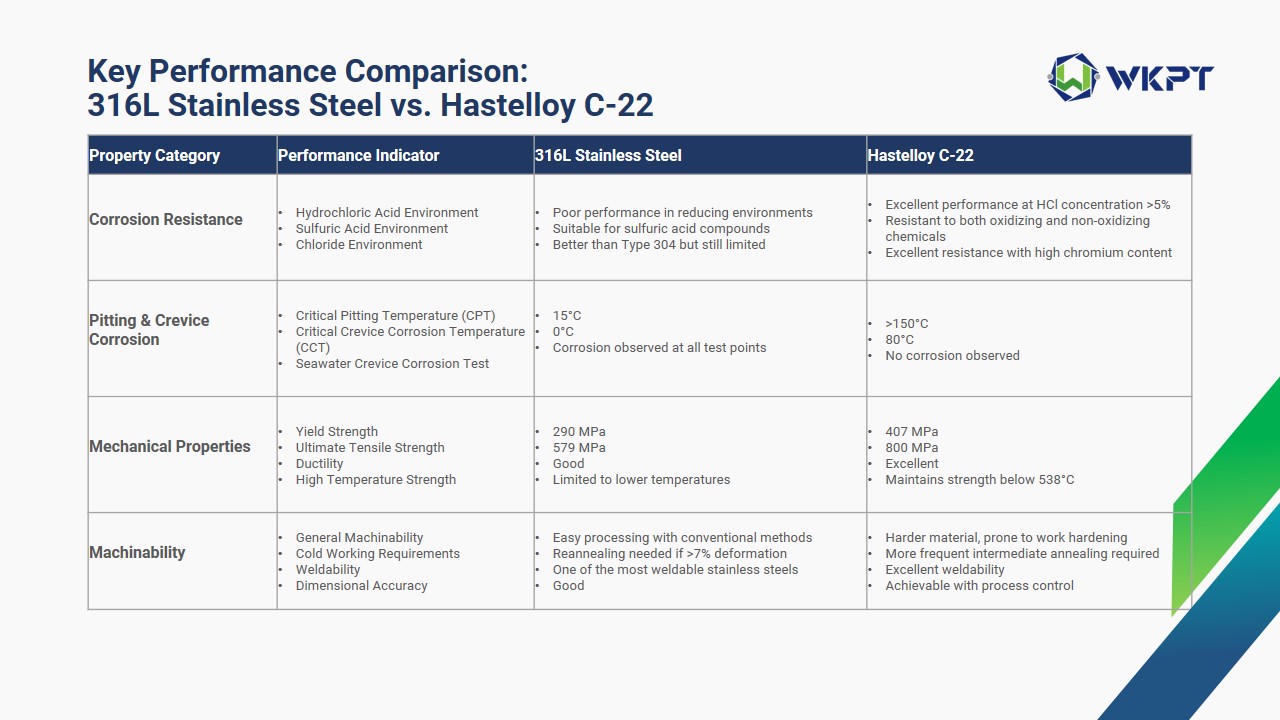

Corrosion Resistance: Hastelloy exhibits exceptional resistance to aggressive chemicals such as hydrochloric acid, sulfuric acid, and chlorides in both high-temperature and low-temperature environments. C-22® alloy in particular demonstrates outstanding resistance to pitting and crevice corrosion in high-chloride environments, which is especially critical for joints and sealing areas in hookup systems.

Mechanical Properties: Based on operating temperature ranges, corrosion-resistant alloys are suitable for corrosive liquid environments below 538°C, while high-temperature alloys can maintain strength at temperatures exceeding 538°C. Compared to conventional stainless steels, Hastelloy demonstrates superior performance under extreme operating conditions.

Weldability and Machinability: C-22® alloy possesses soft characteristics that make it easy to machine into various precision components. While it presents greater challenges in cold working compared to austenitic stainless steels, proper process control enables it to meet the dimensional accuracy and surface quality requirements of hookup systems.

Using semiconductor hookup components provided by World Known Precision Industry as an example, the following characteristics must be considered when machining C-22® alloy:

Machining Operations: Due to Hastelloy's high strength and tendency toward work hardening, precise control is required. For tooling selection, carbide tools are recommended for turning operations, while high-speed steel or carbide tools can be used for milling, and high-speed steel or carbide drill bits are recommended for drilling. When manufacturing hookup fittings, drilling operations should use sharp-point drills with thinned webs to reduce thrust forces. Coolant lubrication should utilize sulfur-chlorinated oil-based coolants containing extreme pressure additives, while avoiding lubricants containing lead, zinc, or sulfides to ensure component cleanliness standards.

Tube Bending: When bending tubing, the bend radius should be set to three times the tube diameter or greater to prevent wrinkling or deformation. Since C-22® alloy is prone to work hardening, intermediate annealing treatments are necessary during multi-stage cold working processes, particularly when material deformation is significant.

Welding Operations: Hastelloy C-22® alloy exhibits excellent weldability and is suitable for common welding methods such as TIG and MIG. Pre-weld cleaning is extremely important and must thoroughly remove grease, oxides, and other contaminants to ensure weld purity. Welding should employ low to moderate heat input using stringer bead techniques, avoiding wide weaving motions. For temperature control, preheating is typically unnecessary, but interpass temperature should be controlled within appropriate ranges.

Precision Grinding: Various grinding operations including cylindrical, centerless, internal diameter, and surface grinding can be performed. Operating parameters should maintain wheel speeds at 6,000-6,500 surface feet per minute (SFM) with appropriate coolant. Primary applications include surface preparation, oxide layer removal, and weld defect treatment, typically using 80-120 grit wheels with progressively finer grits to achieve required surface finish standards.

Electropolishing (EP): is a critical technology for achieving ultra-high cleanliness levels. EP thoroughly removes surface contamination layers and forms a chromium-rich passive layer that provides corrosion resistance. Process keys include pre-mechanical polishing of workpieces, electrolyte formulation, and control of voltage and current parameters. Its stress-free processing characteristics make it particularly suitable for thin-wall component treatment while achieving mirror-like surface finishes that meet semiconductor process cleanliness requirements.

World Known Precision Industry possesses diversified manufacturing service capabilities, ranging from pipe fittings and housings to complex geometrical components, covering complete processes including casting, machining, heat treatment, and surface treatment. Our product applications span across major industries including renewable energy, transportation, agriculture, machinery, and construction, with extensive material processing experience encompassing cast iron, carbon steel, stainless steel, aluminum alloys, copper alloys, and Hastelloy materials.

Through close collaboration with suppliers and comprehensive quality control systems, World Known Precision Industry not only meets general industrial machinery application requirements but also possesses the capability to handle high-precision, high-cleanliness components such as semiconductor hookup systems. We utilize advanced process control technologies, from material selection and process optimization to quality verification, providing complete Hastelloy hookup component manufacturing solutions.

By choosing World Known Precision Industry as your manufacturing partner, you will receive reliable technical support and quality assurance, helping you maintain competitive advantages in the highly competitive semiconductor equipment market.

Reference

半導體廠二次配工程供應商選擇模式研究

HASTELLOY®C-22®

Design Guidelines for the Selection and Use of Stainless Steel