Thread Machining Methods Comparison: Turning, Milling, and Tapping

-

Tracing the Origin of Thread Machining

The roots of thread machining date back to the Industrial Revolution in England during the late 18th century. Initially established on lathe machines, modern thread machining has evolved to encompass milling, screw tapping, rolling, and thread-making machines. Threads find widespread use in mechanical engineering, serving as vital connections and power transmission components.

Threading is a common machining technology. WKPT generally provides turning, milling, or tapping on thread machining

Threading is a common machining technology. WKPT generally provides turning, milling, or tapping on thread machining - Thread Turning

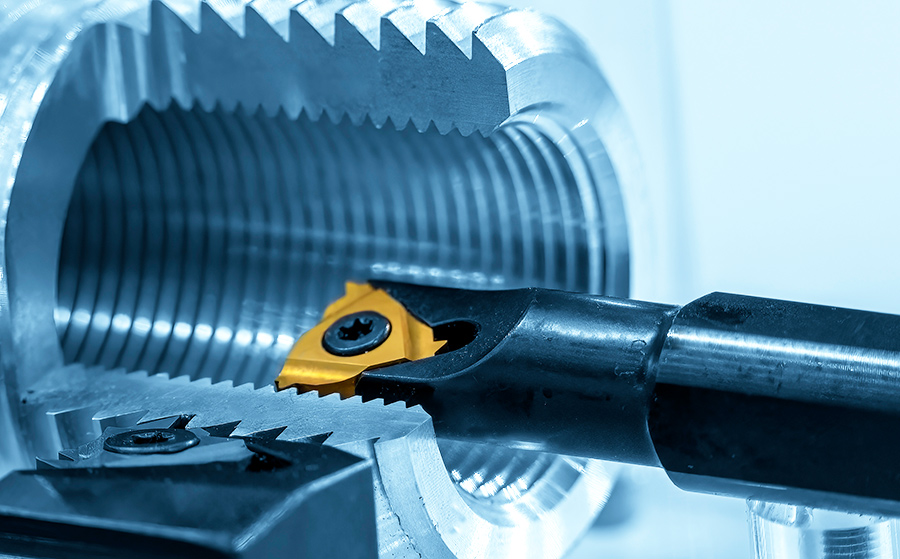

Cutting threads using shaping tools or thread tools on a rotating workpiece, thread turning is typically performed on a lathe, its capability to produce highly accurate internal and external threads suitable for creating various thread forms and profiles. Thread turning often provides a superior surface finish compared to other thread machining methods, making it ideal for precision applications.

But thread turning process is slower compared to other thread machining methods, which can be a limitation in high-volume production settings.

- Thread Milling

Uses milling cutters to cut large-pitch internal and external threads is often assisted by NC (numerical control) programming for precision is ideal for low to medium-volume production and is commonly used in the manufacturing of precision components such as shafts, screws, and fasteners. Milling cutters used in thread milling typically have a longer lifespan compared to tapping tools, making them more durable and cost-effective over time.

- Thread Tapping

Thread tapping is creating internal threads in holes using thread tools, known as taps and ideal for creating threaded holes in softer materials like aluminum, brass, and plastics which are highly efficient and commonly can lower costs compared to other thread machining methods. Thread tapping is especially common in applications that require a high number of threaded holes, such as automotive, machinery, and consumer electronics industries.

Thread Milling Service - Precision Connections and Transmissions by WKPT

World Known Precision Industry Co., Ltd. (WKPT) is a comprehensive metalworking service provider, offering total metalworking solutions from design, and material supply, to expert production. One of our specialized services is thread machining, which includes lathe turning, milling, and screw-tapping techniques.

3 Types of Thread Machining

WKPT excels in three general types of thread machining services:

-

Quality Control and Inspection for Thread Machining

To ensure exceptional quality, WKPT conducts a thorough inspection and quality control after thread machining. We utilize thread inspection equipment, including ring thread gauges, 2.5D image measuring machines, to verify various thread parameters. From internal/external thread measurements to major/minor diameter, thread depth, pitch, and thread angle, our meticulous inspection guarantees customer satisfaction with our thread machining services.

Key Factors Influencing Thread Precision

Thread precision is of utmost importance for successful connections and efficient power transmission. Several critical factors affect the accuracy of threads, including:

- Stability of Clamping

Proper clamping force is crucial to avoid offset or damage during machining. - Rigidity of Machining Center

Higher rigidity minimizes vibrations, resulting in superior finished product accuracy. - Precision of Tools

Different material properties impact tool wear and can affect thread machining precision. - Level of the Controller

A higher-level controller converts motion commands more accurately, leading to improved finished product precision.

- Stability of Clamping