Surface Treatment Process

Environmentally Friendly Chromium-Free GEOMET® Surface Treatment Process

-

GEOMET® coating is developed by the esteemed NOF METAL COATINGS GROUP is an environmentally conscious, water-based, completely chromium-free coating and aligns with RoHS and REACH specifications, adhering to international environmental protection standards.

GEOMET® offers exceptional features, including salt spray and cyclic corrosion resistance, high heat and corrosion resistance, and prevention of galvanic corrosion with aluminum. Its superior coating adhesion performance, coupled with freedom from hydrogen embrittlement concerns, further enhances its appeal. Additionally, GEOMET® allows for the application of additional coatings, making it a versatile and reliable surface treatment solution.

WKPT has embraced the environmentally friendly chromium-free GEOMET® surface treatment process, this advanced technology is based on the DACROTIZED® anti-rust coating, perfected through three decades of practical application.

GEOMET® is a registered trademark of the company. Its logo and content are owned by the company.

GEOMET® is a registered trademark of the company. Its logo and content are owned by the company.

-

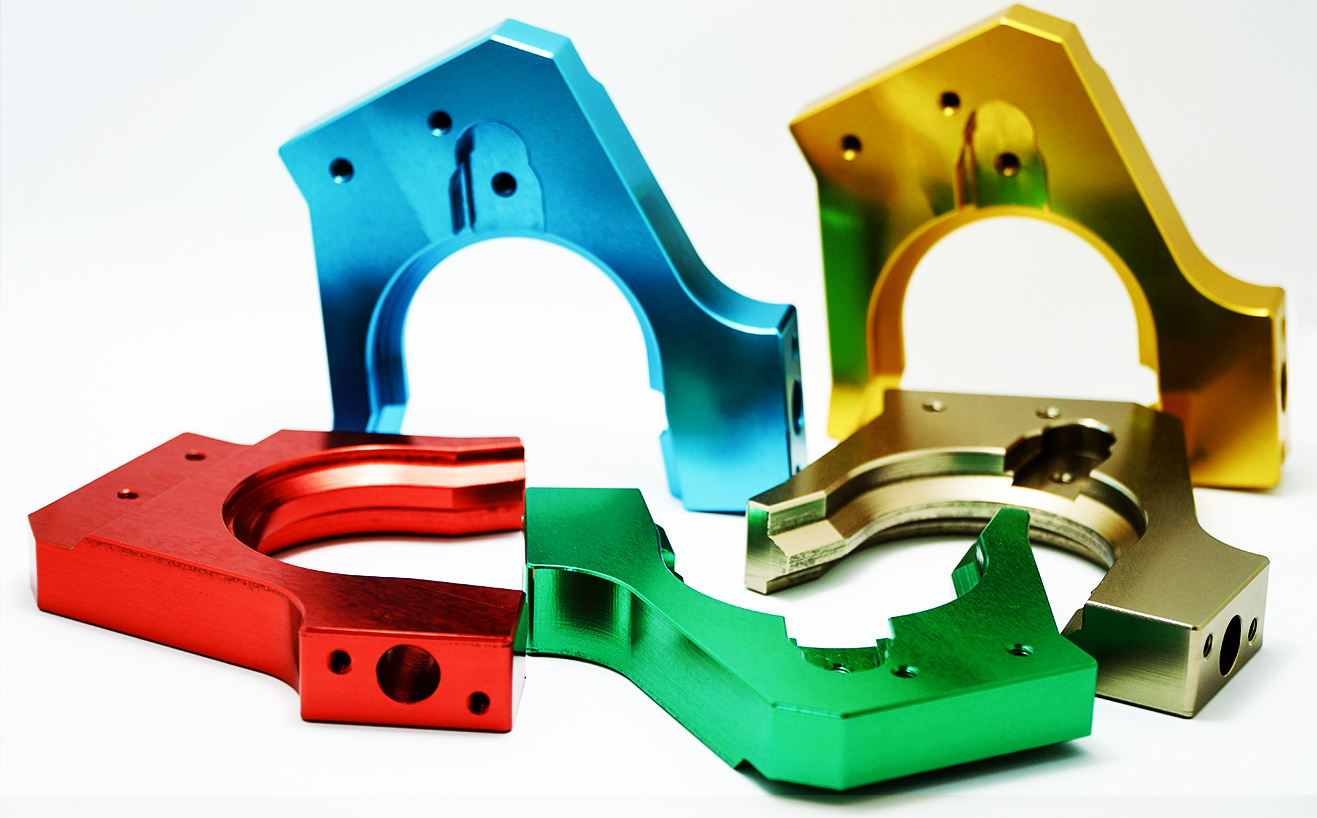

Surface Treatment Technology for Aluminum Alloy Components

For aluminum alloy machining components, WKPT employs anodizing and hard anodizing surface treatments. Anodizing controls the formation of an oxide layer on the aluminum surface, offering insulation, corrosion resistance, and wear resistance. Powder coating, known for its hardness and resistance to acids and wear, is also applied to aluminum alloy machined parts.

CNC machined aluminum parts with an anodized aluminum finish.

CNC machined aluminum parts with an anodized aluminum finish.

-

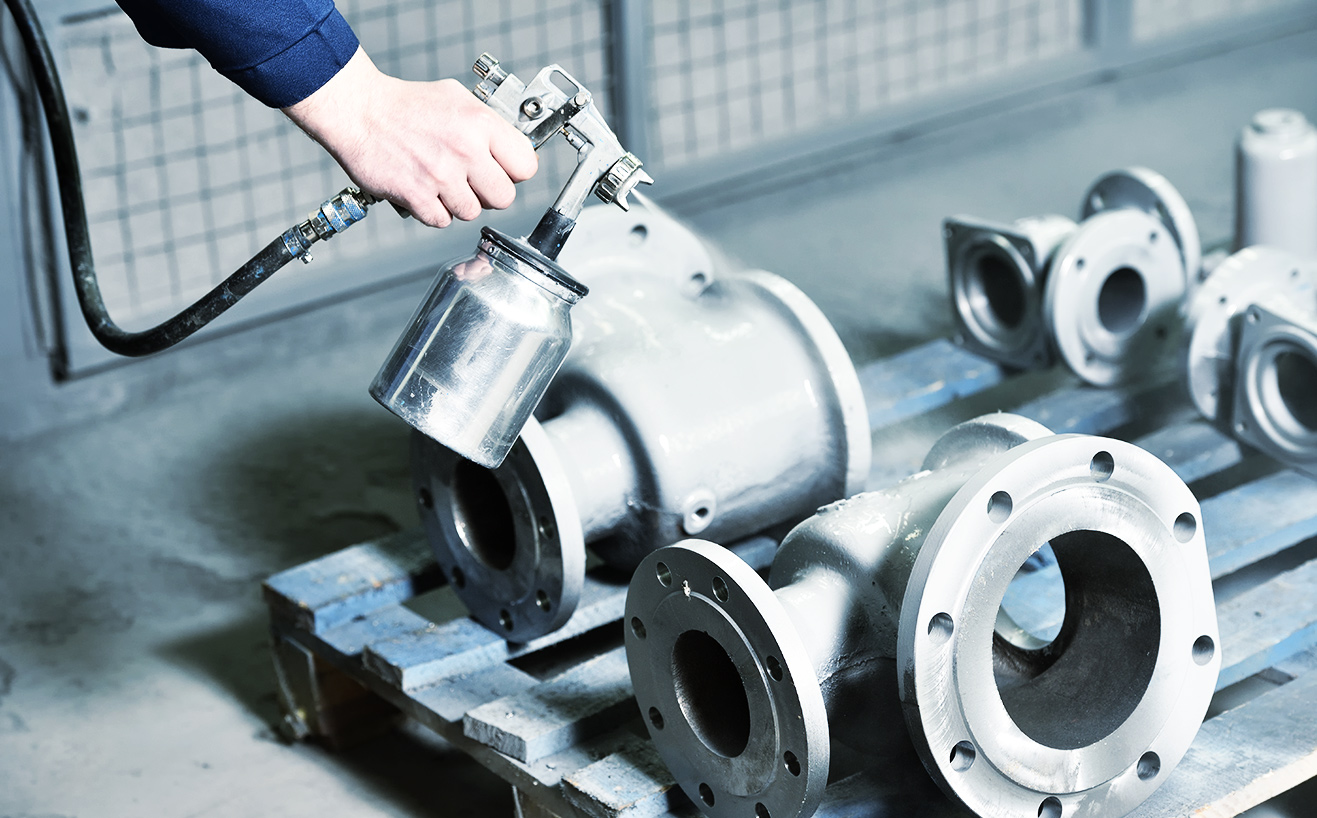

Surface Treatment for Cast Iron, Stainless Steel, and Carbon Steel Machining Parts

WKPT provides surface treatment services such as liquid coating, powder coating, and ED coating for iron-based materials, including cast iron, stainless steel, and carbon steel components. Our factory is equipped with liquid coating facilities, complemented by an overhead conveyor system and sewage treatment system.

The liquid coating uses a special formulation to achieve the required surface thickness through multiple sprays.

The liquid coating uses a special formulation to achieve the required surface thickness through multiple sprays. -

Innovative Surface Hardening Protective Layer

To enhance wear resistance, corrosion resistance, and fatigue strength, WKPT employs the latest soft nitriding treatment technology to form a surface-hardening protective layer for cast iron metal components. Our integrated approach combines surface coating with component machining, streamlining production and ensuring optimal results.

Advancing with Powder Coating Facilities

In our commitment to quality and timely delivery, WKPT continues to expand its powder coating facilities. By closely connecting powder coating and liquid coating technologies with the manufacturing process, we gain a competitive edge in quality control and customer satisfaction.

-

Experience the Difference with WKPT's Metal Surface Treatment Service

WKPT's metal surface treatment service enhances the performance and longevity of your metal components. Through our environmentally conscious approach and state-of-the-art surface treatment technologies, we deliver solutions that exceed expectations and align with global sustainability standards.

Metal Surface Treatment Service - Elevating Performance with Environmentally Conscious Solutions by WKPT

World Known Precision Industry Co., Ltd. (WKPT) is a comprehensive metalworking service provider, offering total metalworking solutions from design and material supply to expert production. One of our specialized services is metal surface treatment, where we employ cutting-edge technologies to enhance the performance and durability of metal machined parts.