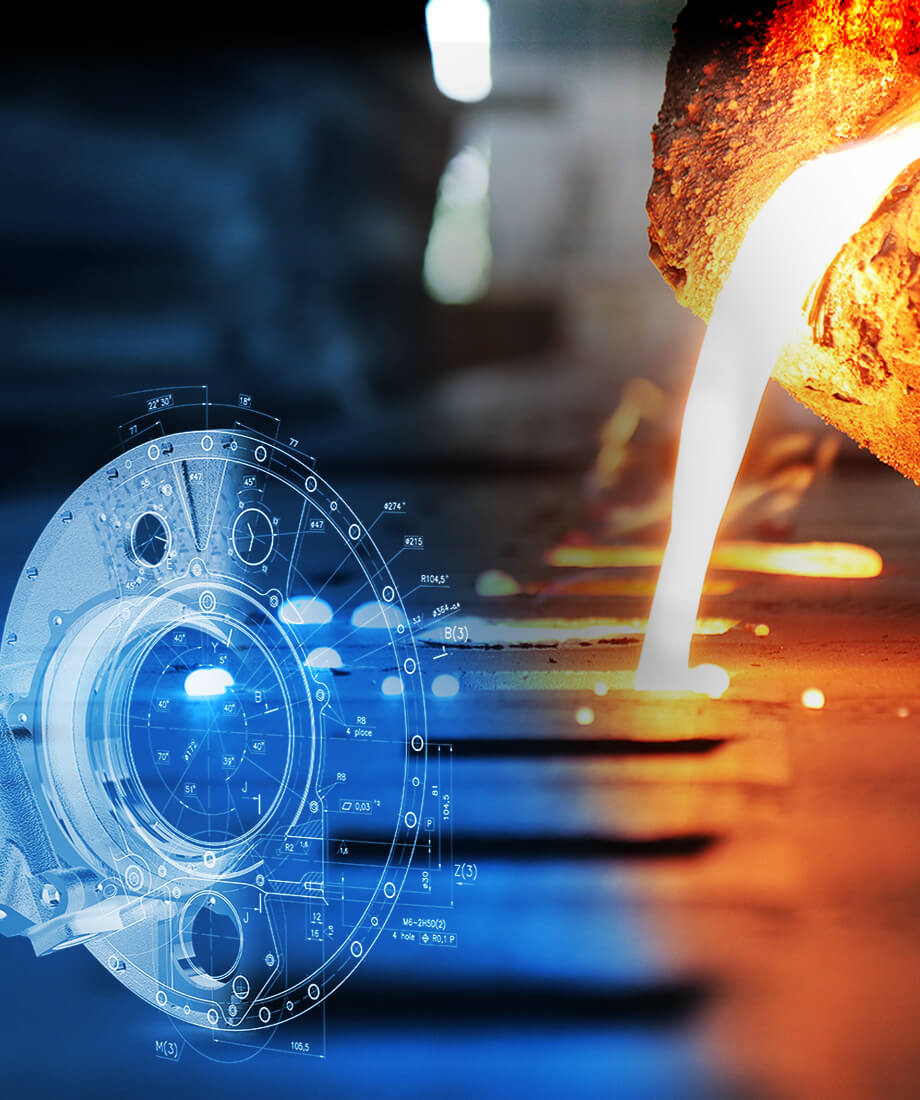

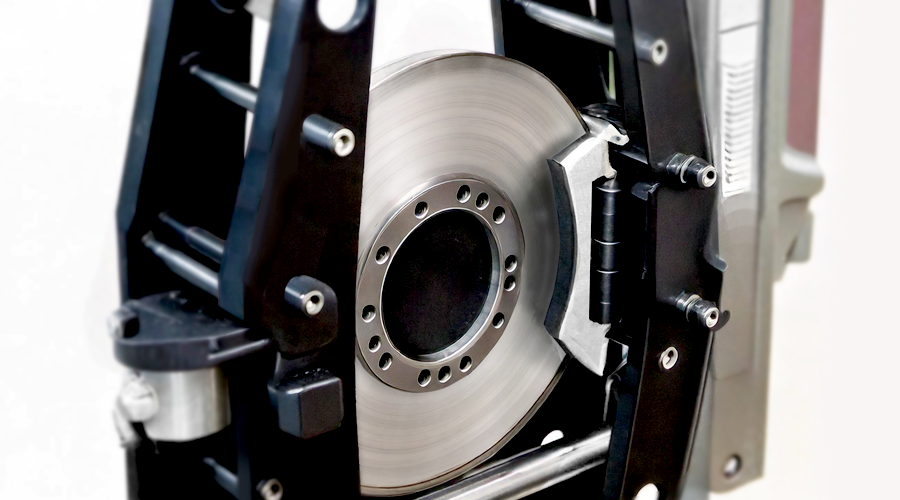

WKPT is Taiwan's largest supplier of commercial vehicle metal processing parts. Its products cover multiple fields including the automotive industry, construction machinery, and agricultural machinery. The company's core technology is multi-process metal processing, focusing on machining, surface treatment and blank forming technology of iron and aluminum materials to ensure high product quality. The main products include commercial vehicle chassis, torsion plates, shock absorber brackets, etc., which account for more than 70% of the total parts of its transportation vehicles.