Knowledge Base

-

Does cast iron rust? Why do machine tool beds favor cast iron over steel? From gray iron to ductile iron material evolution, explore how carbon content determines mechanical properties and how modern rust prevention technologies extend the lifespan of cast iron products.

-

Why is Hastelloy chosen for secondary piping in semiconductor processes? Discover how this superalloy maintains ultra-high purity in harsh corrosive environments with hydrofluoric acid and sulfuric acid, and how precision machining techniques ensure component quality.

-

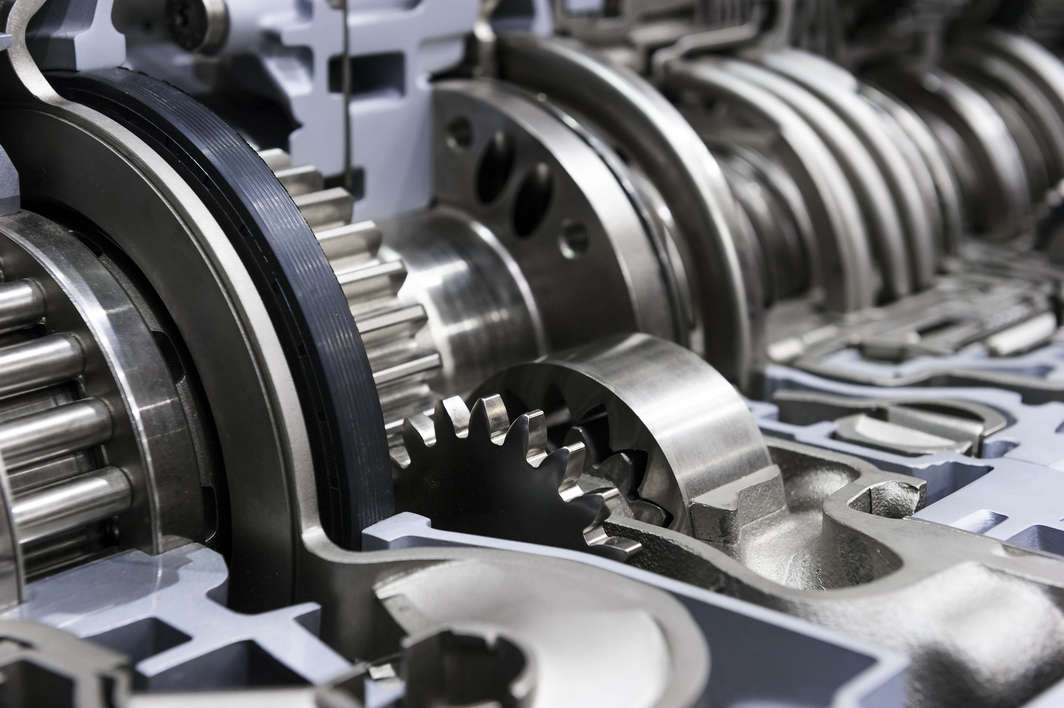

As the electric vehicle era arrives, how can transmission housings achieve both lightweight design and high strength? Discover the material revolution from cast iron to aluminum alloys, and how mold flow analysis prevents manufacturing defects.

-

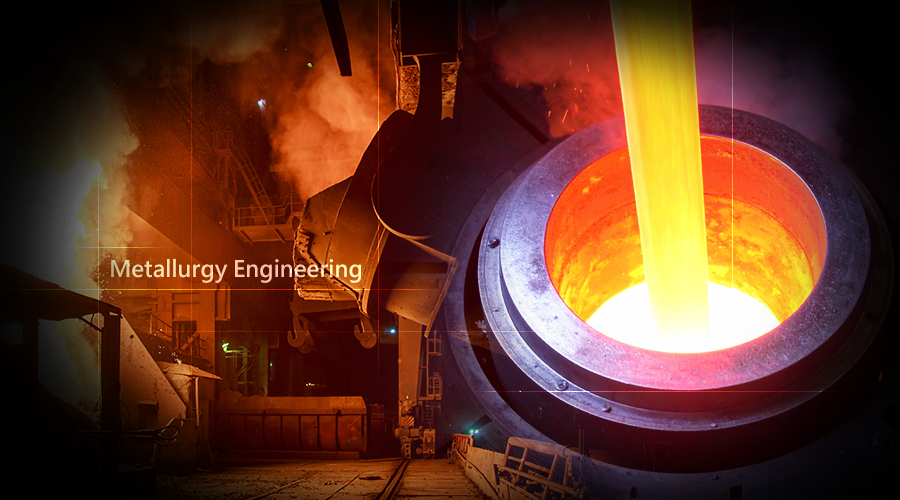

The birth of metal materials originates from smelting technology. The process from iron ore to diversified applications demonstrates the crystallization of human wisdom. Carbon content, as a key factor in determining metal properties, not only distinguishes pig iron, cast iron and various types of carbon steel, but also provides diverse options for product design. Whether it is low-carbon steel with excellent toughness, medium-carbon steel with balanced strength and toughness, high-carbon steel with optimal hardness, or gray cast iron with shock absorption ability, high-strength ductile iron, they all play an irreplaceable role in modern industry...

-

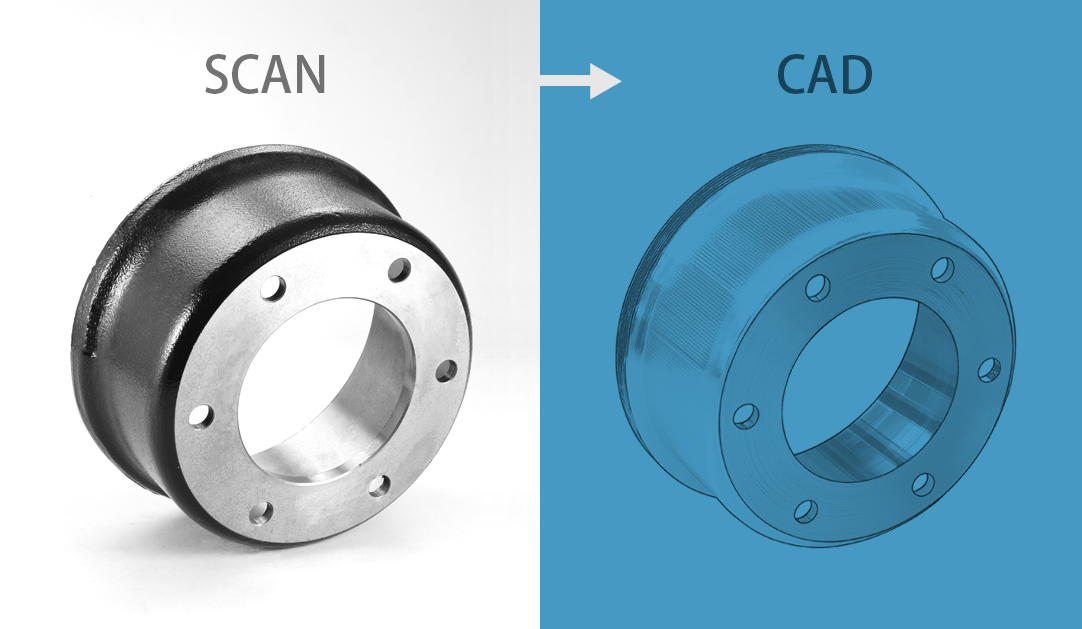

WKPT provides complete reverse engineering solutions through information acquisition, modeling and verification processes to help customers accelerate product development, strengthen supply chain resilience, and achieve product optimization and upgrades.

-

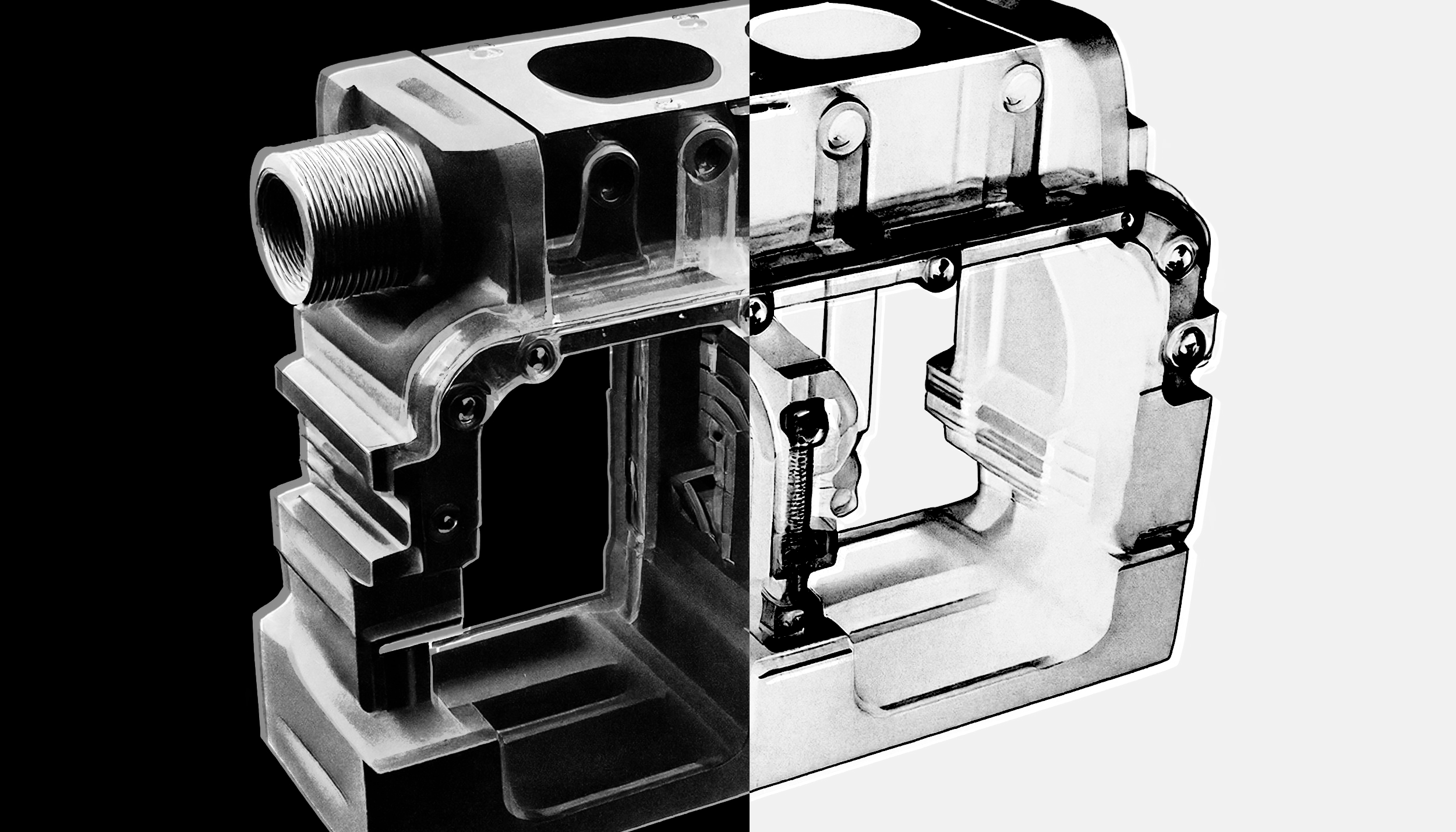

In addition to building an automatic optical identification system (AOI) to detect surface defects of parts, WKPT has also introduced X-ray inspection equipment that can penetrate aluminum alloy parts to deeply detect the fine structure inside the parts and provide a full range of non-destructive testing services to ensure that the quality of parts meets the highest standards.

-

Discover how machine vision and AI are revolutionizing quality control in metal manufacturing. Learn about the limitations of manual inspection, the benefits of smart technologies, and how WKPT successfully implemented AI-powered visual inspection to improve efficiency and product yield.

-

Energy storage systems have become an indispensable part of modern power infrastructure. To ensure the stable operation of energy storage systems in various harsh environments, high-quality metal casings have become a key factor in the safe operation of energy storage systems.

-

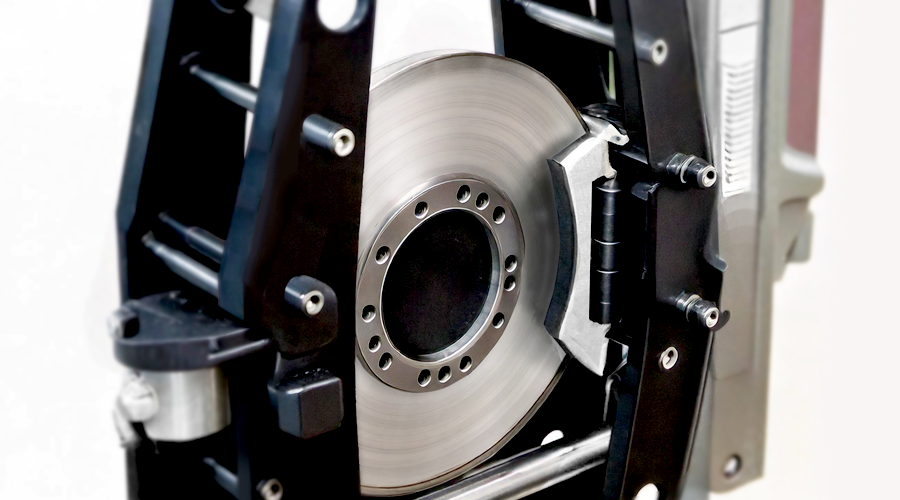

High-quality industrial brake system components are the key to maintaining safe operation of equipment. Especially in heavy industrial fields such as port cranes and construction machinery, the reliability of the brake system significantly affects operational safety and efficiency.