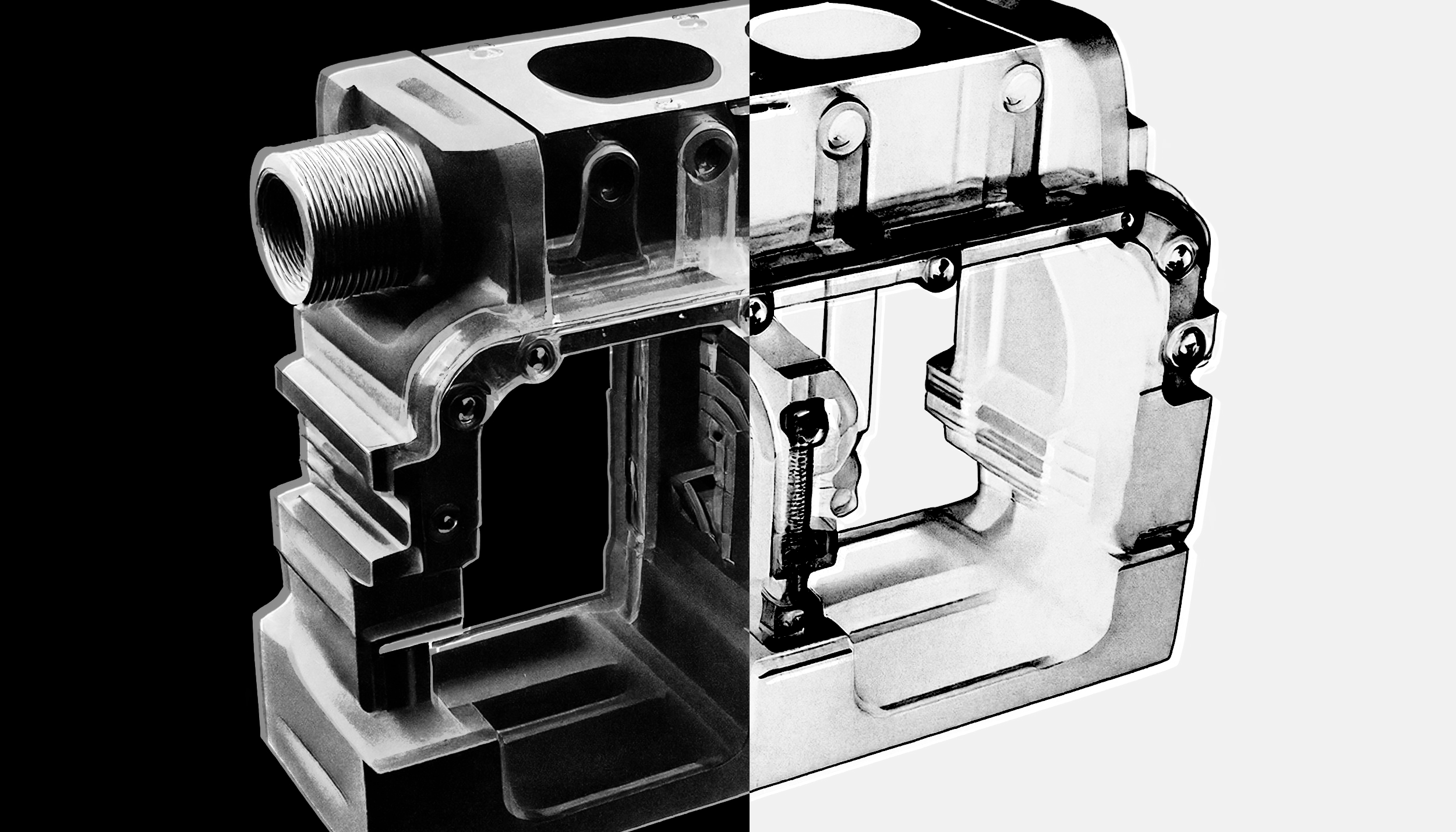

Aluminum alloy parts X-ray quality inspection, structure inspection

In modern industrial production, component quality is crucial to product competitiveness. World Known Precision Industry understands this well. In addition to implementing Automated Optical Inspection (AOI) systems for surface defect detection, the company has introduced advanced X-ray inspection equipment to provide comprehensive non-destructive testing services for automotive components, medical device parts, construction machinery components, agricultural machinery parts, high-precision equipment, and semiconductor industry components, ensuring products meet the highest quality standards.

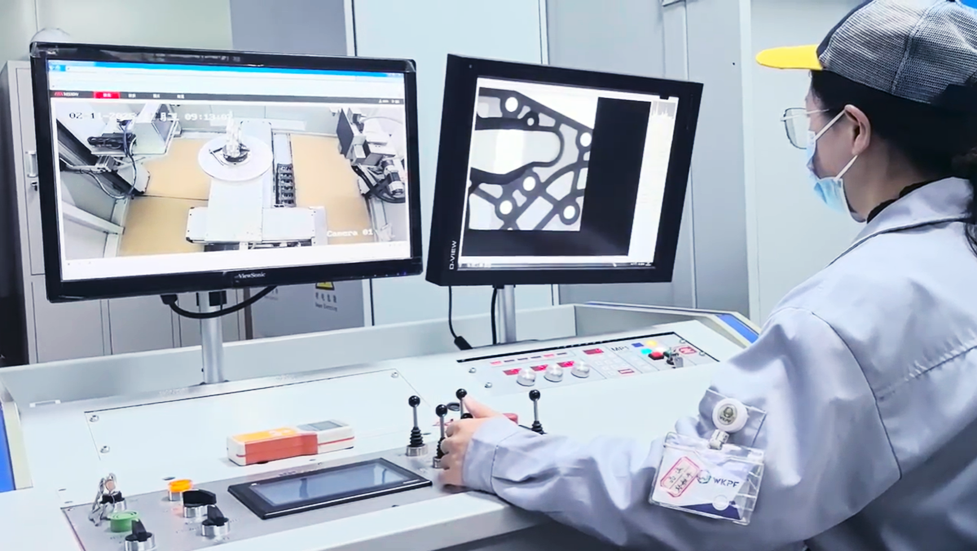

While Automated Optical Inspection (AOI) systems primarily focus on detecting surface defects, they have limitations when examining internal structures or obscured areas of components. X-ray inspection technology effectively penetrates object surfaces to examine detailed internal structures. World Known Precision Industry's seven-axis X-ray inspection equipment offers flexible adjustment of inspection angles and positions, meeting the real-time imaging inspection requirements for diverse components.

- High Flexibility: The seven-axis design accommodates inspection of components with various sizes, shapes, and materials, eliminating the need for frequent equipment changes and significantly improving production efficiency.

- Comprehensive Inspection Capability: Through precise mechanical motion control, workpieces can undergo full-range scanning across X, Y, Z axes, including tilt and rotation, ensuring clear imaging from all angles and effective detection of internal defects.

- Precise Adjustability: The system can flexibly adjust X-ray source energy and select appropriate radiation receivers based on different component materials and thicknesses, ensuring accurate and reliable inspection results.

- Automotive Industry:From engine components and chassis parts to brake system components, X-ray inspection effectively identifies potential defects, ensuring vehicle safety and reliability.

- Medical Device Industry:With safety being paramount in medical devices, X-ray inspection thoroughly examines internal structures, ensuring products meet stringent quality standards.

- Construction Machinery Industry: Construction machinery components endure tremendous pressure and loads. X-ray inspection examines internal defects in structural parts, hydraulic components, and other critical elements, ensuring stability and durability.

- Agricultural Machinery Industry: The reliability of agricultural machinery directly impacts farmers' productivity. X-ray inspection examines engine components and transmission system parts, ensuring machinery reliability and efficiency.

- High-Precision Equipment and Semiconductor Industry: These industries demand extremely high component precision. X-ray inspection effectively detects internal defects in precision parts, ensuring equipment accuracy and stability.

World Known Precision Industry's X-ray inspection technology effectively detects various defects in both metallic and non-metallic materials, including:

- Internal Defects: Air bubbles, sand holes, inclusions, cavities, cracks, etc.

- Structural Features: Weld quality, assembly precision, internal structural integrity, etc.

- Surface Defects: Fissures, scratches, corrosion, etc.

Through automated X-ray inspection machines, World Known Precision Industry not only effectively improves product quality and reduces defect rates but also enhances production efficiency and shortens delivery cycles, providing customers with superior products and services.

Learn more:Visual Inspection Meets AI: The Future of Quality Control in Metal Manufacturing