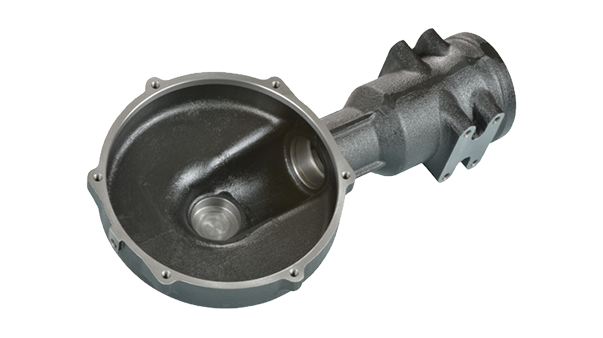

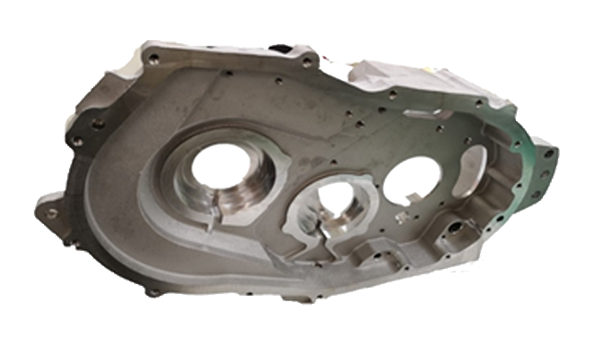

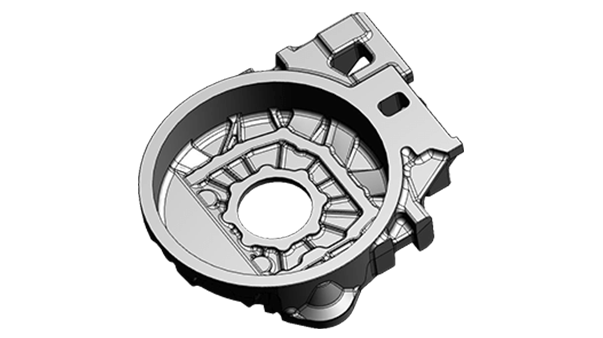

The gearbox housing is the cover of the power transmission system of agricultural machinery. It is made of ductile iron with excellent material properties. The precision and shape tolerance after machining must meet the requirements of the customer's drawing.

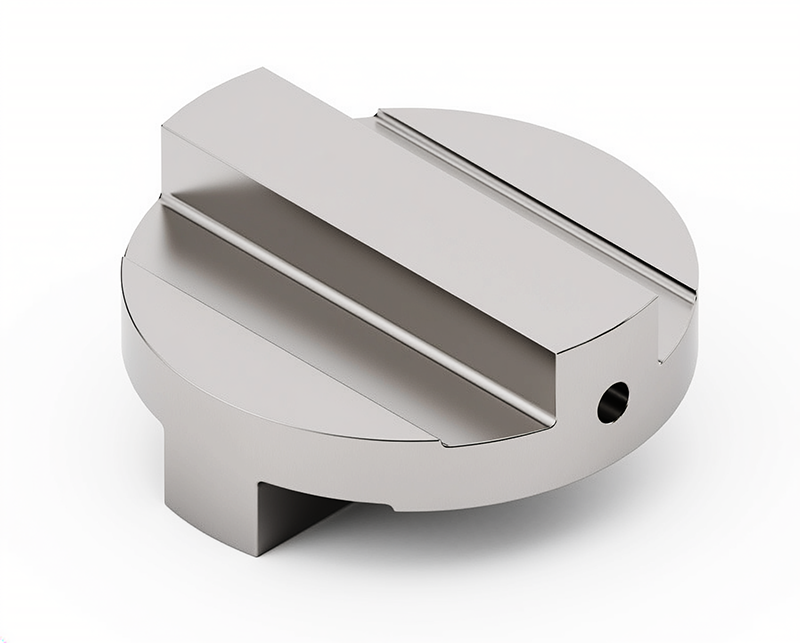

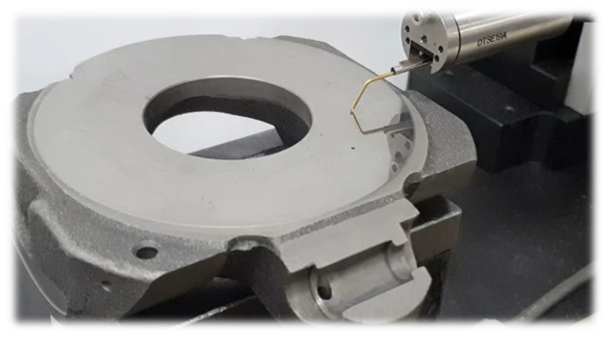

The swash plate of the oil pump has strict requirements on the size, which is not able to be done by ordinary cutting centers. To meet the customer's drawing requirements, hardness enhanced by heat treatment, and grinding process are necessary in the process. Non-contact measurement will be used on partial holes to cover where three dimensional measurements can’t do.

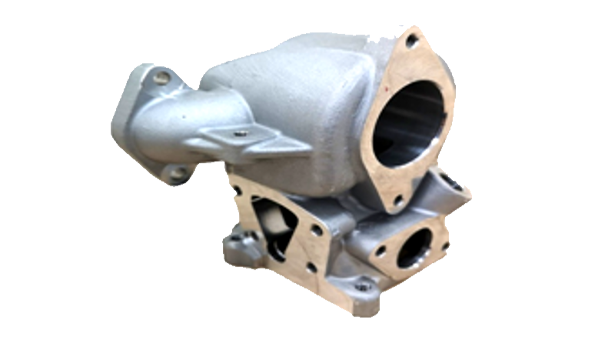

Exhaust gas manifold, EGR (Exhaust Gas Recirculation) body, or automotive secondary intake manifold, secondary exhaust gas upper manifold. The partial product shape and size is shaped by gravity casting aluminum alloy. The aluminum alloy workpiece by gravity casting has stable quality. This makes castings with high precision dimensions and finer surface roughness, which can reduce the range of machining. The exhaust gas manifold is used to guide the exhaust gas back to the intake manifold, making it inhaled and burned by the engine again. Product properties should have high temperature resistance and vibration resistance. The dimension and shape tolerance is required to be below 15μm, and the surface roughness is required to be below Ra1.6.

The gearbox housing is the cover of the power transmission system of agricultural machinery. It is made of ductile iron with excellent material properties. The precision and shape tolerance after machining must meet the requirements of the customer's drawing.

Wind turbine brake parts manufacturing demands exceptional material engineering and precision machining capabilities to ensure reliable operation in extreme environmental conditions across land-based and offshore wind energy applications. WKPT holds the exclusive position as Taiwan's sole supplier of wind turbine brake cylinders, utilizing specialized ductile iron materials with superior low-temperature impact resistance exceeding EN-GJS-LT standards, enabling continuous operation at temperatures far below 0°C. Our comprehensive manufacturing process addresses the unique challenges of heavy workpieces requiring large-scale machining equipment, strict dimensional tolerances, and complex geometries featuring long, deep holes that necessitate specialized tooling solutions. Through advanced surface coating treatments and rigorous 720-hour salt spray resistance testing, WKPT delivers complete brake system solutions including piston components, O-rings, oil seal assemblies, and brake pad design, manufacturing, and assembly services. These critical safety components serve diverse industries including land wind energy, offshore wind energy, industrial brake systems, construction machinery, marine vessels, and offshore heavy industry applications where reliable braking performance is essential for operational safety and equipment protection.

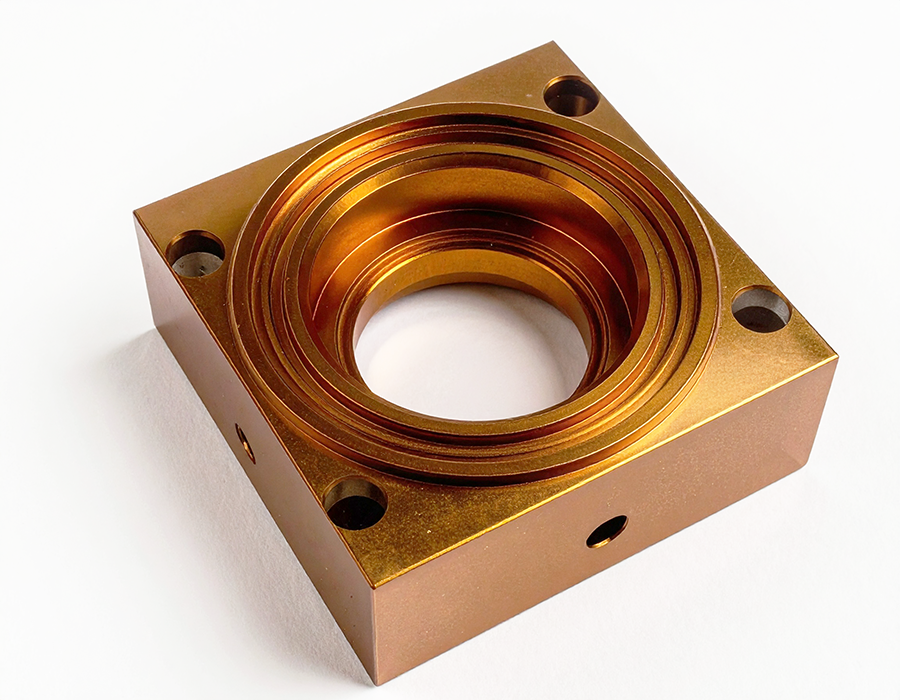

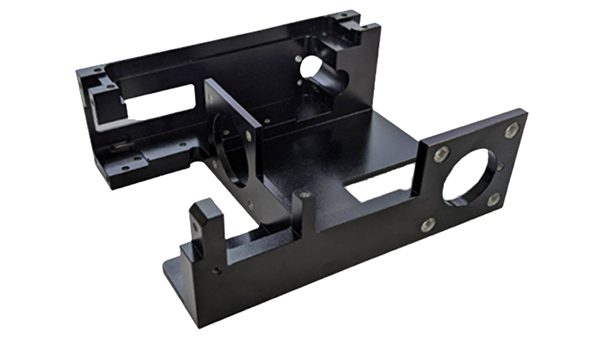

PCB bracket manufacturing for electronic machinery requires exceptional precision and dimensional stability to support critical printed circuit board assemblies in demanding electronic applications. WKPT specializes in producing aluminum alloy PCB brackets through advanced gravity casting processes, delivering components with superior quality characteristics including stable material properties, high-precision dimensions, and refined surface finish that significantly reduces subsequent machining requirements. Our spindle brackets for PCB punching machines meet stringent specifications with dimensional tolerances under 10μm, shape tolerances under 15μm, and surface roughness below Ra 1.6, ensuring optimal performance in electronic machinery, data communication devices, passive components, printed circuit boards, and electronic tube applications. Through specialized customization capabilities, WKPT manufactures complete bracket assemblies with upper and lower seat configurations, utilizing gravity casting techniques that save both material consumption and processing time while maintaining the exacting standards required for electronic component manufacturing.

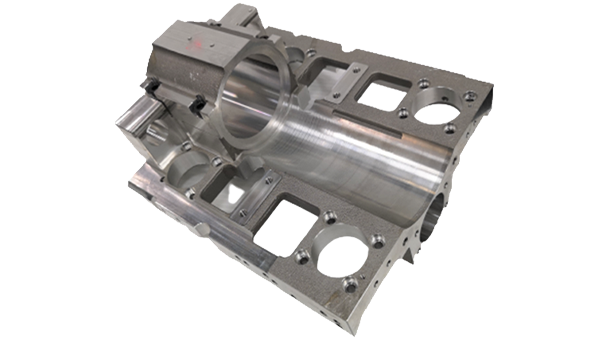

After multiple tests by the development team, mass production will be begun after the quality is confirmed by the customer. Since the product requires high mechanical properties, including tensile strength and hardness, the manufacturing process is set aluminum alloy blocks for full engraving, which also increases the difficulty of processing and process time. In addition, at least two or more machine tools are used in the manufacturing process for multi-axis machining, and the product size is prone to deviate due to deformation during the cutting process. Therefore, it is necessary to adjust the machining procedure to reserve the machining amount, and refine in the final stage to ensure that the final product meets the requirements of dimensional tolerance and shape tolerance.

Transmission shafts represent critical precision components designed to operate in high-temperature environments and harsh operating conditions, demanding exceptional material stability and strict accuracy requirements for automotive gearbox applications. WKPT has pioneered Taiwan's first smart production line specifically for shaft manufacturing, incorporating IoT digitalization, real-time computing technology, automatic dispatching systems, and precision parameter compensation to achieve zero-defect automotive industry standards. Our advanced manufacturing capabilities combine cast iron expertise with precision CNC turning, grinding, and five-axis machining technologies, delivering transmission spindles that meet stringent automotive specifications. Through intelligent manufacturing processes and quality control systems certified to IATF 16949 and ISO 9001 standards, WKPT ensures optimal production line utilization rates and superior product yields for vehicle transmission applications requiring exceptional durability and precision performance.

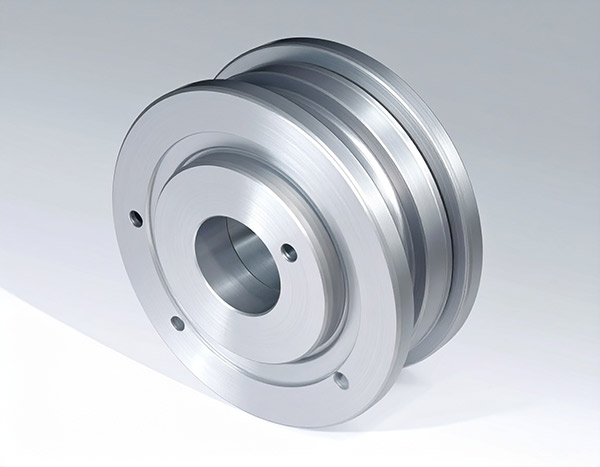

Power supply bearing is the friction part which is capable of bearing external force and vibration. So it is necessary

to add other alloy into normal material as casting parts to improve overall mechanical properties.

Besides, casting defects are not allowed, especially on machining.

Construction machinery is used in harsh environments, especially high temperature and high strength resistance to engine flywheel housing. For this kind of product feature, tough material with solid structure is considered for manufacturing. In order to have outstanding assembly quality, there are rigorous demands on the surface of machining and casting. We have high standard checking defects and flatness, as well as surface roughness by controlling the process precisely, to reach accuracy requests.

Construction machinery always works under harsh environments. Its hydraulic system bears the loading of the excavator all-around, so the hydraulic cylinder is considered with high-pressure resistance. Such product properties are suitable for tough ductile cast iron without any casting defects which may leak inside. In order to increase operation stability, standard such as concentricity and surface roughness are strictly applied on machining precision. High precision specs guarantee that all processes are done precisely.