Technique

-

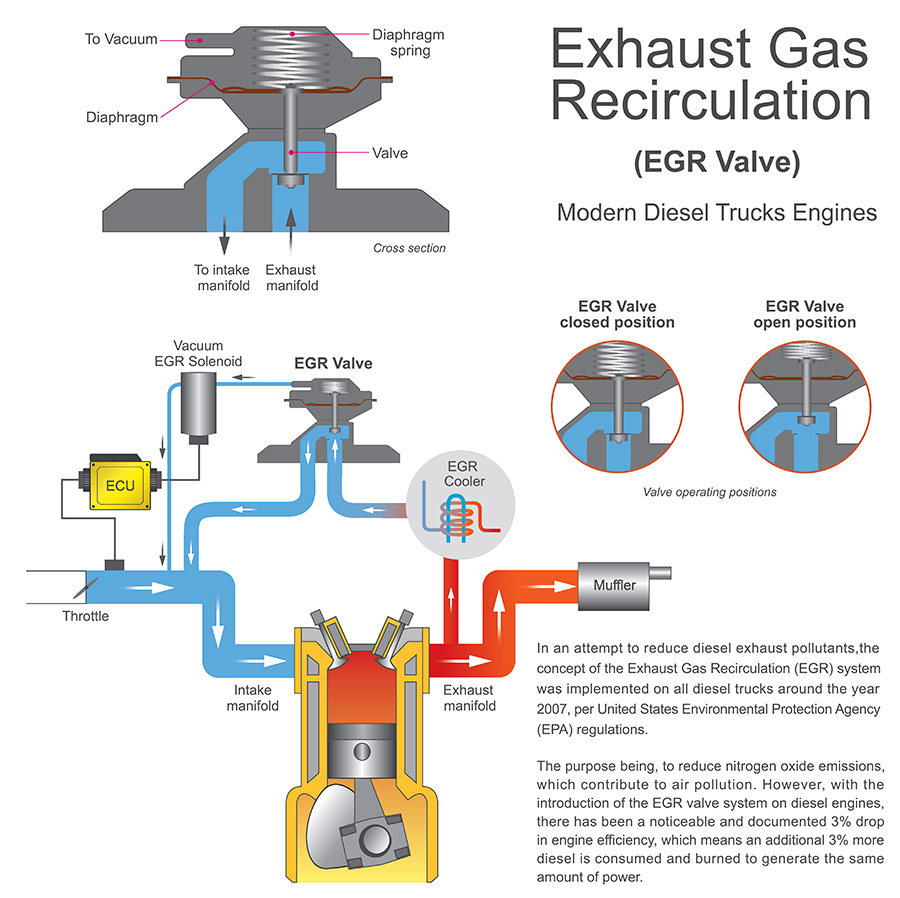

What is EGR? How does EGR contribute to environmental protection? Introduction to common EGR materials, quality standards, and development trends.

-

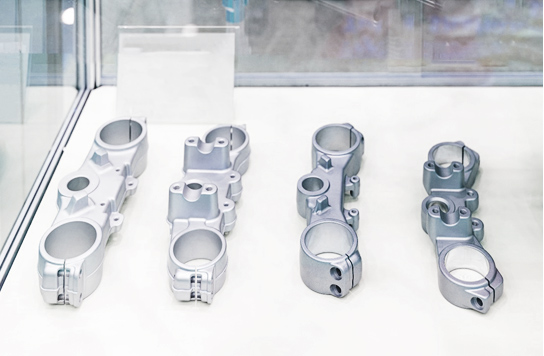

The casting industry predominantly manufactures cast iron parts, with non-ferrous metals comprising a minority share. Casting products find applications across various sectors, including transportation, agricultural machinery, construction engineering, renewable energy, and medical engineering. In the automotive and aviation industries, heightened environmental awareness has spurred the development of lightweight products to minimize energy consumption, prompting advancements in casting technology. This article provides a brief overview of the evolving development trends in casting technology in response to market demands.

-

Global trends indicate that environmental protection has become a universal value, with countries worldwide recognizing the importance of energy conservation and carbon reduction.

-

WKPT is the only supplier of brake cylinders for wind energy, committing ourselves to wind power in Taiwan.

-

Surface treatment is a common and important process technology in the metal manufacturing industry. As various forms of corrosion and wear in the environment often begin on the surface, implementing surface treatment can protect the underlying material from surface corrosion and damage. Surface treatment technologies have also been developed with various material characteristics and resulted in a range of options.

-

Aluminum alloy is a highly active metal. An oxide film will occur as soon as the aluminum alloy contacts the air, and this can isolate the possibility of the bottom layer being corroded in the environment. However, the naturally formed oxide film still will be corroded after long-term exposure, so aluminum alloy is usually anodized for surface protection.

-

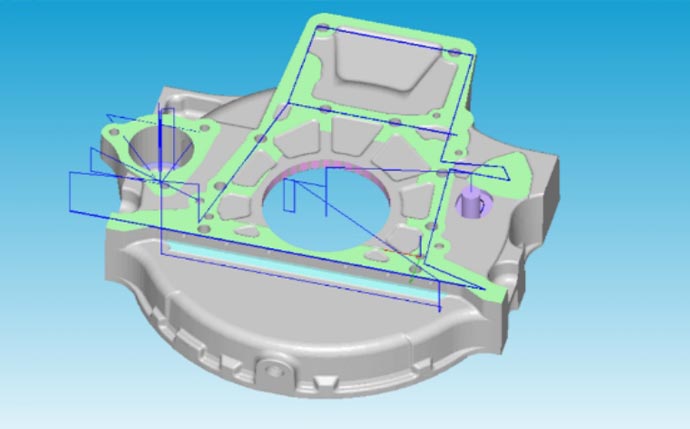

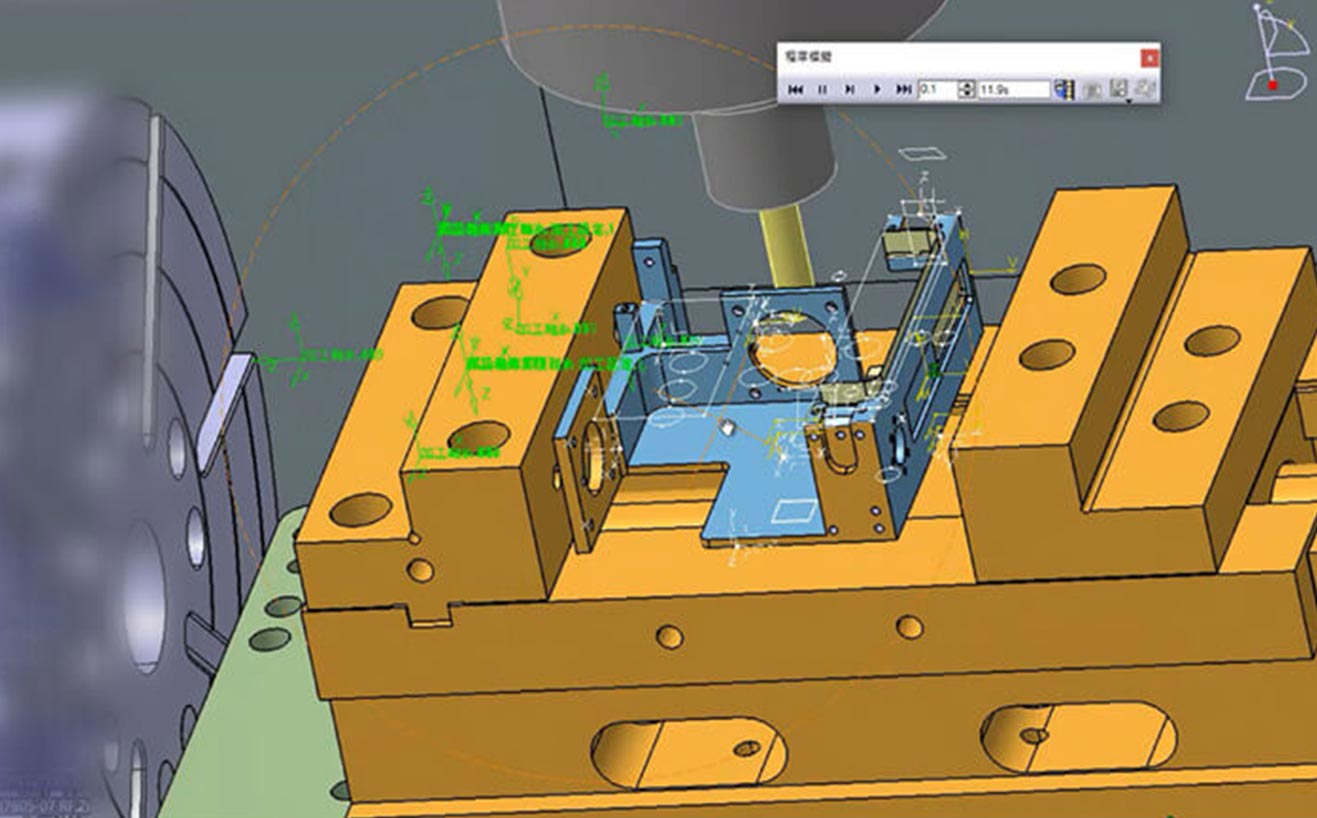

CATIA was developed in the 1980s by French software design company Dassault Systèmes S.A. It was originally used for aircraft manufacturing and later expanded to other product design applications, including automobile, vessel, and other consumer goods. With technology developing, the application of CATIA has been spread to the aviation, national defense, transportation, high technology, industrial equipment, construction, and biomedical industries.

-

One of our precision metalworking solutions is assembly and welding. Welding is the technique of joining metals or other materials by means of heat or pressure. Modern welding technology first appeared at the end of the 19th century and has developed various welding methods, such as gas welding, arc welding, laser beam welding, etc. Among the metal materials that we commonly use, cast iron is known for its high elongation, and stainless steel is high temperature and corrosion resistant, which is a commonly used metal material under the modern energy-saving trend. Various metals have their own properties, and it is expected to have a hybrid positive effect on the application of products.