Machining

Total

10

-

WKPT discovered abnormal tool vibration during a machining process and immediately initiated a root cause analysis. The team employed the 4M1E method to comprehensively investigate the causes of the problem. This serves as one of many root cause analysis examples in the manufacturing sector. Based on the investigation results, the company designed and implemented a complete solution:

-

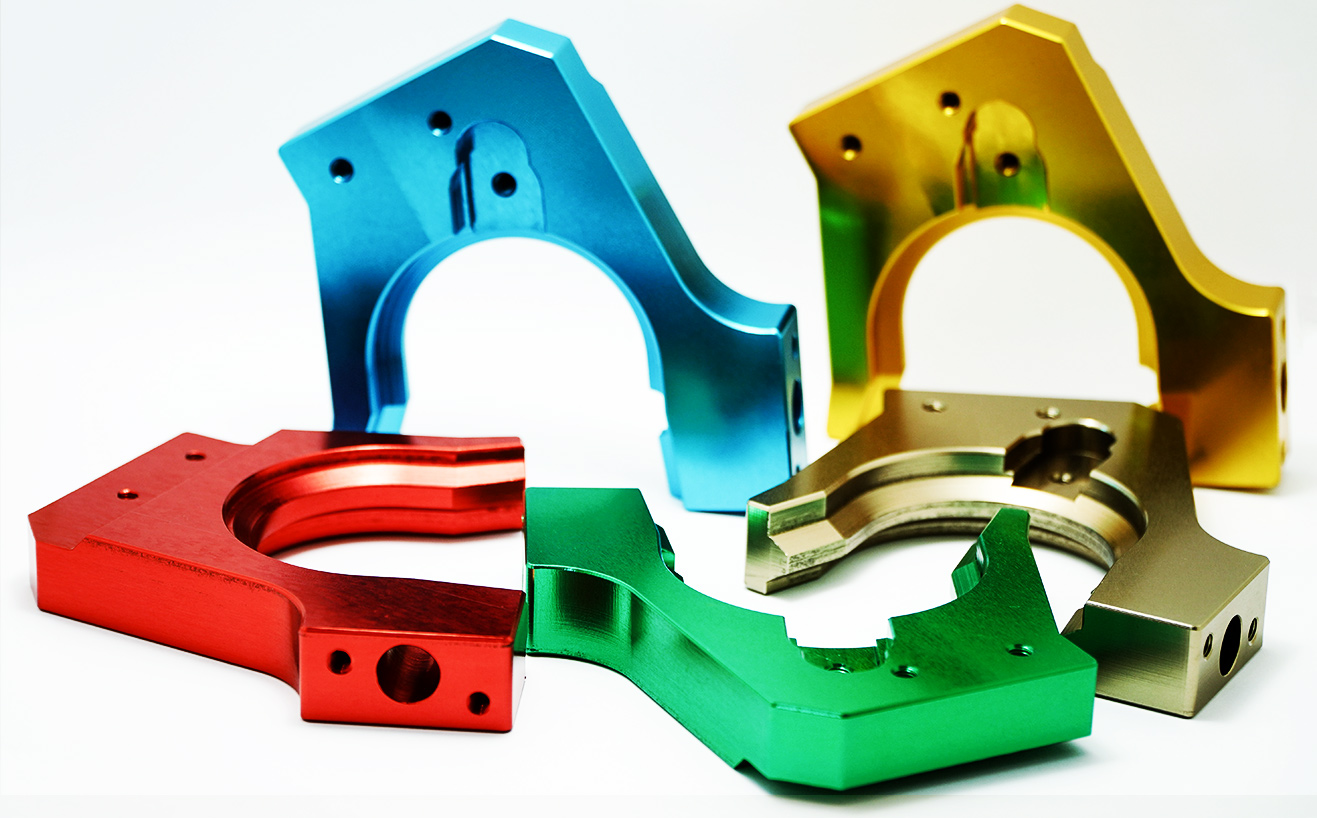

WKPT provides surface treatment services such as liquid coating, powder coating, electroplating, etc. on machined parts such as aluminum alloy, cast iron, stainless steel, and carbon steel. The surface treatment of aluminum alloy parts is mainly anodizing and hard anodizing.

-

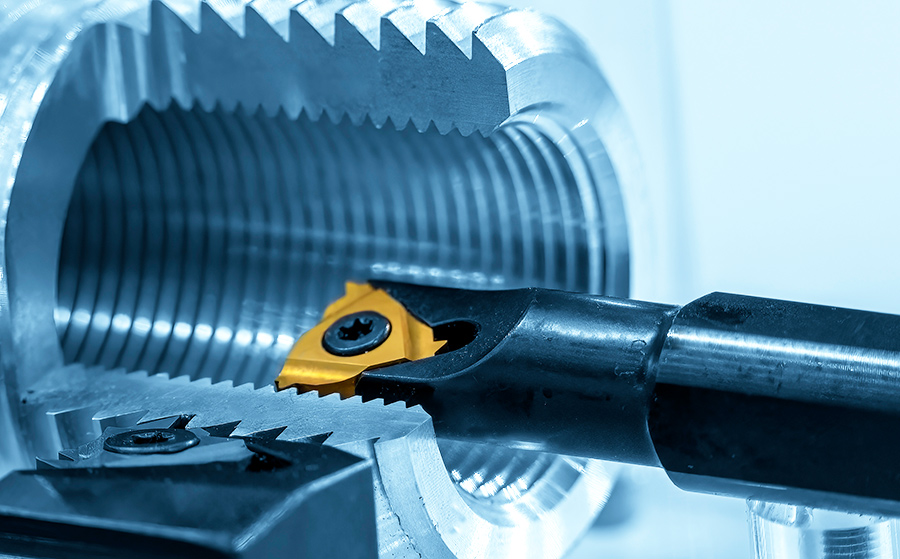

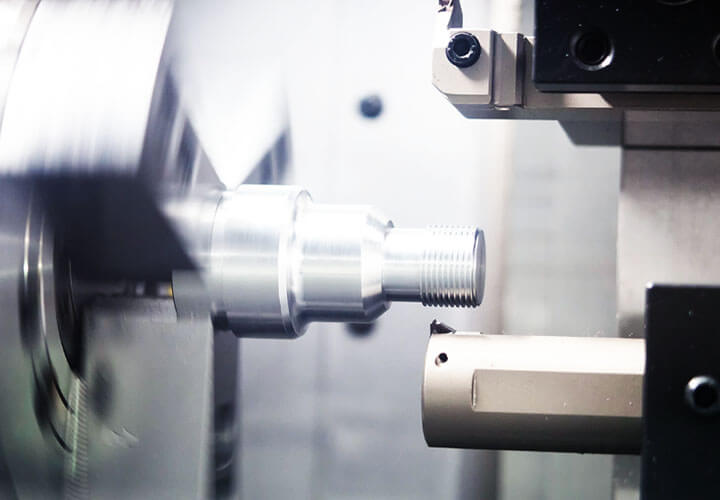

Thread machining services: thread turning, thread milling, and thread tapping. Thread turning involves cutting with shaping tools or thread tools on a rotating workpiece, suitable for precision manufacturing of internal and external threads in small quantities.

-

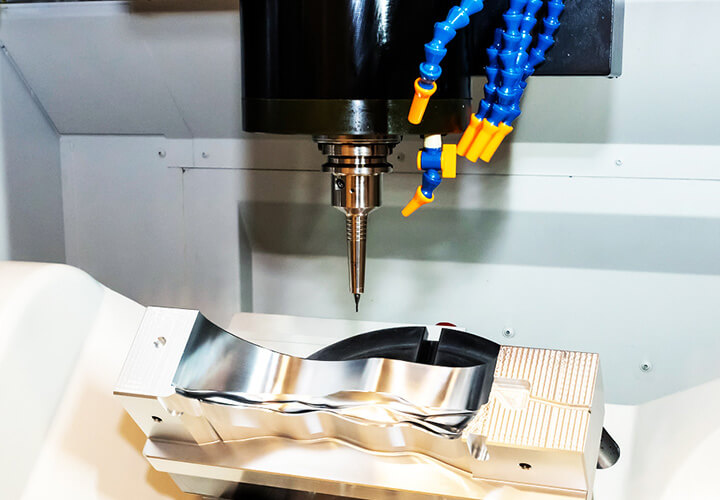

The development of the five-axis machining center and the turning-milling machine is for complex precision parts production, and the needs of machining parts with multiple angles or negative angles.

-

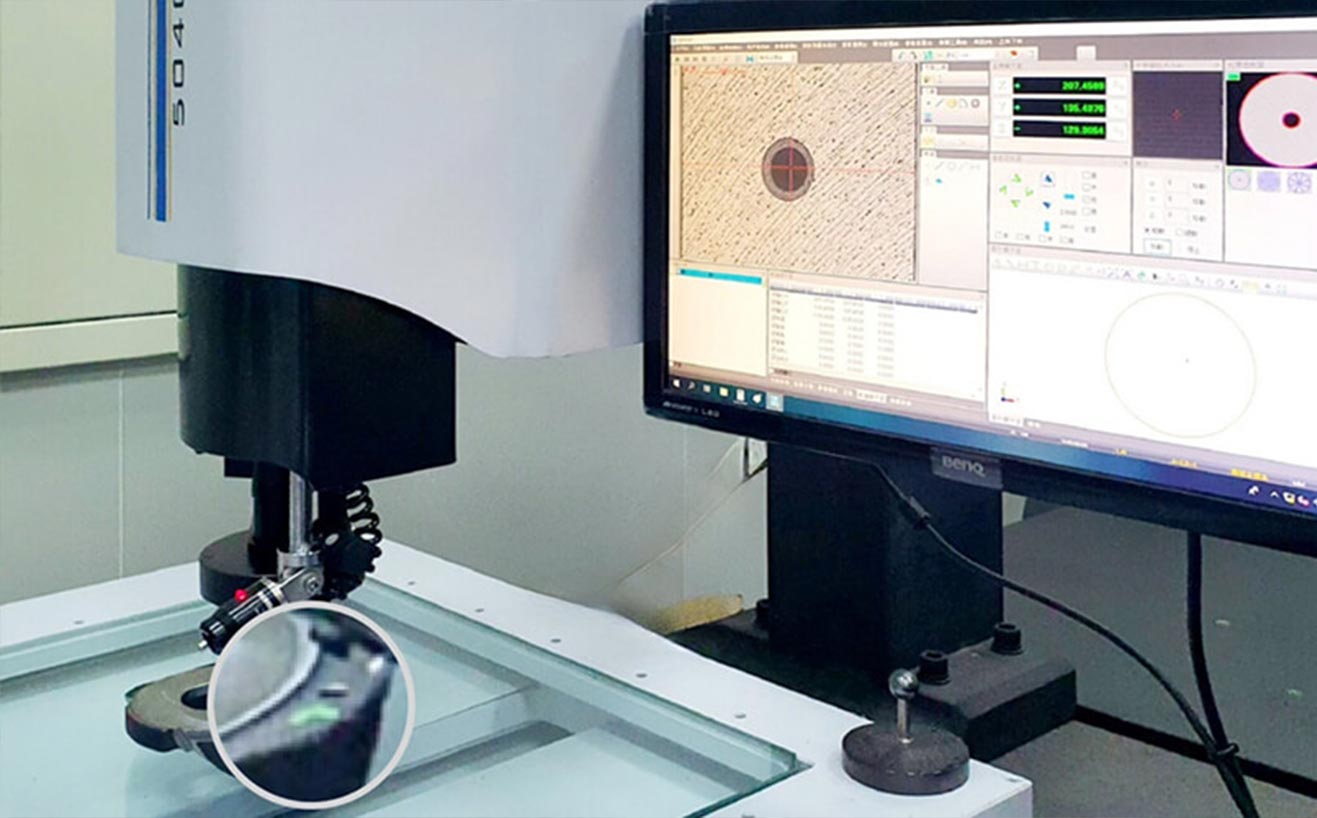

The precision quality of industrial products continuously improving, and the requirements of precision of parts manufacturing are also higher than before, which has reached the demand of micrometers (㎛).

-

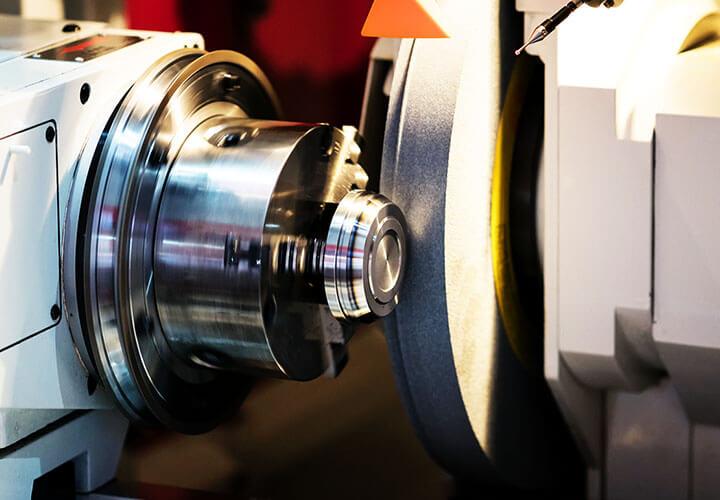

Lathes play an important role in industry development, known as the mother of industry, and is the most important machinery in precision machining.

-

A milling machine is a device that fixes the workpiece on the main shaft of the machine tool and removes the material by the high-speed rotation of the tool.

-

In the precision machining industry, we discuss the feasibility of product projects with customers, starting from a sheet of drawing. The drawing carries all the information of the workpiece, and its dimensions, tolerances, and machining methods including details of the customer's product, which is also the key to measuring whether we would undertake this project or not.

-

WKPT’s automatic production line consists of an Italian COMAU NS series six-axis robotic arm, which can grip 16 kg materials, and the repeatability accuracy reaches 0.05mm. Also with COMAU Rebel four-axis robotic arm can grip 6 kg materials and the repeatability accuracy reaches 0.02mm.