Turning

Expert Precision CNC Turning Services for High-Quality Machined Parts

World Known Precision Industry Co., Ltd. (WKPT) is dedicated to offering comprehensive CNC turning services for the production of high-quality machined parts. With our position as a reliable company in the industry, we provide one-stop turning machining solutions that cover design, material supply, and expert machining production.

-

Understanding CNC Turning and Its Applications

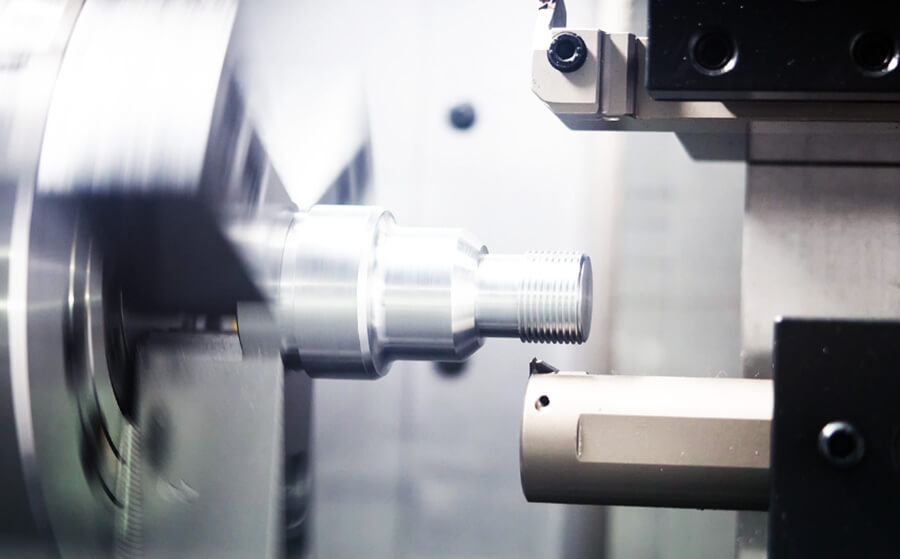

CNC turning, a fundamental machining process, involves fixing the workpiece on the main shaft of the machine tool, where it rotates at high speed while a cutting tool shapes it linearly. This versatile process allows us to perform various operations, including cylindrical turning, internal turning, face turning, slope turning, curved surface machining, thread cutting, knurling, grooving, drilling, boring, embossing, and eccentric turning, among others.

CNC lathes are used for the machining of auto parts. The precision of the lathe affects the quality of the machining.

CNC lathes are used for the machining of auto parts. The precision of the lathe affects the quality of the machining. -

WKPT's Advanced CNC Turning Machinery

To cater to different project requirements, WKPT maintains a wide array of CNC turning machinery, including horizontal lathes and vertical lathes. Our vertical lathes offer excellent rigidity and load capacity, making them suitable for large-scale and long-diameter workpieces. On the other hand, our horizontal lathes are ideal for medium and small parts with clamping limitations based on size and weight.

Materials Expertise in Turning Machining

At WKPT, we have a wealth of experience in machining various materials with precision. Our capabilities have evolved from machining cast iron and carbon steel to working with stainless steel, aluminum alloys, and lightweight materials like nickel-zinc alloys. We understand that each material requires specific parameters, tool selections, configurations, and corrections during the machining process. Our expertise in handling diverse materials is a testament to the stability of our lathes and the proficiency of our CNC engineers.

-

Investment in High-Performance CNC Lathes

To meet the demands of high-value-added manufacturing, WKPT continuously invests in cutting-edge CNC lathes. In addition to high-torque metal machining centers, we have incorporated high-speed multi-axis turning centers to bolster our machining capacity for high-precision aluminum alloy production lines.

Ensuring Accuracy and Precision

At WKPT, precision is paramount. We meticulously check the quality of parts through offline measurement. For projects with higher precision requirements, we employ turning and milling centers that allow for online measurement and automatic workpiece offset correction. Automatic tool correction further enhances tool life, reduces precision errors, and improves overall efficiency.

-

Experience the Excellence of WKPT's CNC Turning Services

From concept to completion, WKPT offers expert precision CNC turning services to deliver high-quality machined parts that meet your exact specifications. With our state-of-the-art machinery and skilled professionals, we guarantee precision, efficiency, and utmost satisfaction for all your CNC turning needs.

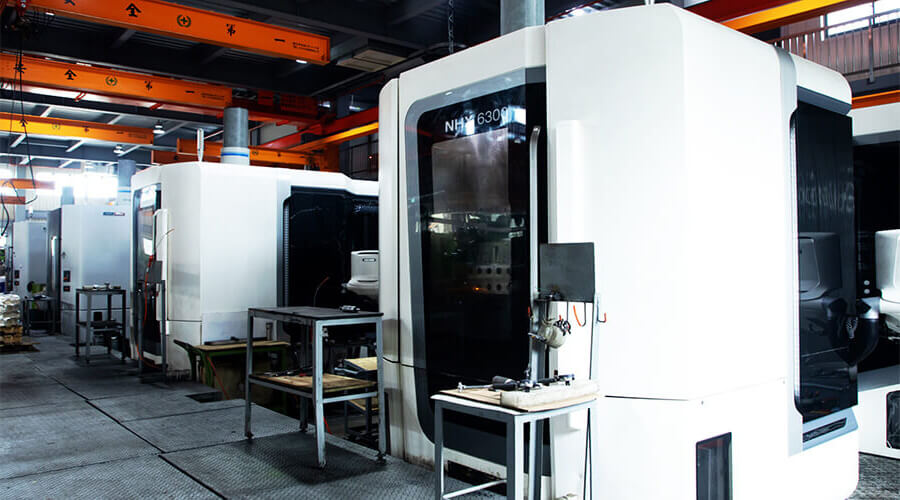

We use the DMG MORI horizontal machining center in the prototyping and production of high-precision workpieces.

We use the DMG MORI horizontal machining center in the prototyping and production of high-precision workpieces.

| Types of Equipment | Brand/Spec | Working Range | Q’ty | ||

|---|---|---|---|---|---|

| X Axis | Y Axis | Z Axis | |||

| Horizontal Machining Center | DMG MORI NHX-4000 | 560mm | 560mm | 660mm | 1 |

| Horizontal Machining Center | DMG MORI NHX-6300 | 1050mm | 900mm | 1030mm | 4 |

| Horizontal Machining Center | KAFO HMC-630 | 1100mm | 825mm | 885mm | 1 |

| Vertical Machining Center | Tongtai TMV-760A | 760mm | 450mm | 530mm | 1 |

| Vertical Machining Center | Tongtai TMV-850A | 850mm | 500mm | 530mm | 6 |

| Vertical Machining Center | Tongtai TMV-1100A | 1100mm | 530mm | 530mm | 4 |

| Vertical Machining Center | Champmill e-1100 | 1100mm | 610mm | 610mm | 3 |

| Vertical Machining Center | KAFO VMC-106 | 1020mm | 600mm | 635mm | 7 |

| Vertical Machining Center | KAFO VMC-137 | 1300mm | 700mm | 700mm | 1 |

| CNC Vertical Turning Center | Tongtai TVL-6DA | 760mm | - | 385mm | 2 |

| CNC Vertical Turning Center | Tongtai TVL-40 | 390mm | - | 285mm | 6 |

| CNC Vertical Turning Center | Victor Taichung VTURN-V760 | 780mm | - | 380mm | 1 |

| CNC Horizontal Turning Center | Victor Taichung Vturn-26 | 360mm | - | 600mm | 2 |

| CNC Horizontal Turning Center | Tatung OKUMA L400-E | 390mm | - | 520mm | 4 |

| 5-Axis Machining Center | Champmill C50-5A A-Axis Travel +30˚~-120˚ C-Axis Travel 60˚(Continuous) |

810mm | 700mm | 610mm | 1 |

| 5-Axis Machining Center | FFG U-600P A-Axis Rotation+110°~-90° C-Axis Rotation 360° |

460mm | 620mm | 400mm | 1 |

| 5-Axis Machining Center | Quaser UX600 | 885mm | 800mm | 500mm | 1 |

- Vertical Machining Center:

Products of machining range under length of 1300mm and width of 700mm. - Horizontal Machining Center:

Products of machining range under length of 1050mm and width of 900mm. - Vertical Turning Center:

Products of machining range under a diameter of 780mm. - Horizontal Center:

Products of machining range under a diameter of 390mm.

The distance between each aperture could be controlled under 0.01mm (special request), or under 0.02mm (normal request).

| Equipment | Spec | Q’ty |

|---|---|---|

| Ultrasonic Cleaning Machine | - | 2 |

| High-Pressure Water Jet Cutter | - | 1 |

| Equipment | Spec | Q’ty |

|---|---|---|

| Automatic Welding Equipment | - | 1 |

| Equipment | Description | Q’ty |

|---|---|---|

| Liquid Coating Line | Coating, Drying | 1 |

| Equipment | Description | Q’ty |

|---|---|---|

| Liquid Leak Detection Machine | - | 1 |

| Gas Leak Detection Machine | - | 1 |