Our Engineering Techniques for Superior Metal Parts

Total

25

-

Surface treatment is a common and important process technology in the metal manufacturing industry. As various forms of corrosion and wear in the environment often begin on the surface, implementing surface treatment can protect the underlying material from surface corrosion and damage. Surface treatment technologies have also been developed with various material characteristics and resulted in a range of options.

-

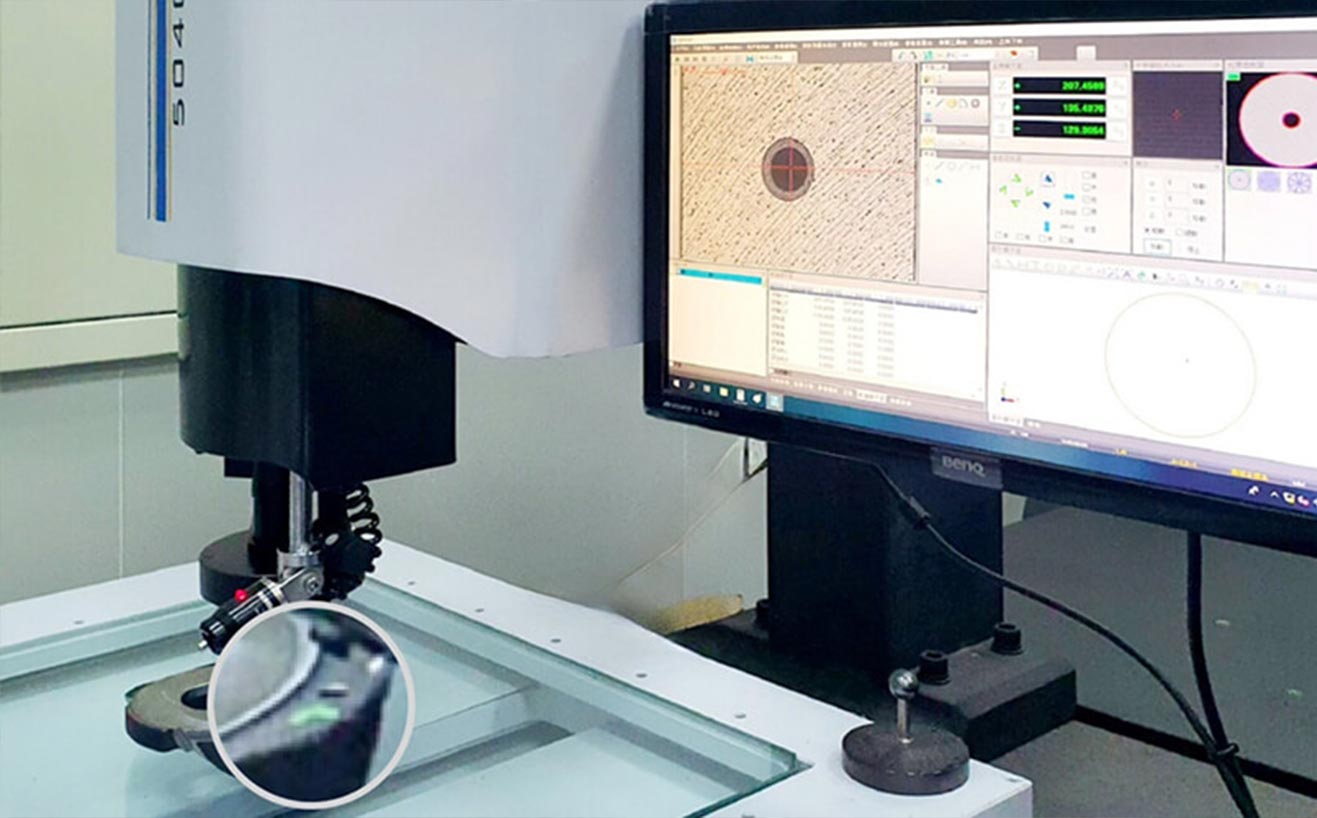

Micro aperture measurement represents a critical challenge in precision machining where traditional measurement tools encounter limitations when dealing with tiny holes of 1mm diameter or less. WKPT employs advanced image measuring instruments that utilize non-contact optical measurement technology to overcome the probe limitations of conventional three-dimensional measuring instruments (CMM), enabling precise measurement of microscale apertures with exceptional geometric tolerance accuracy. This sophisticated measurement approach involves magnifying the target through optical systems to obtain precise dimensional data while offering programmable features for synchronized high-volume measurements and rapid results acquisition. While basic GO/NO GO pin gauges provide immediate aperture feedback for sorting applications, image measuring instruments deliver the precise dimensional data required for quality control in precision machining applications. WKPT's comprehensive measurement methodology selection ensures optimal inspection approaches for various workpiece dimensions and conditions, supporting precision quality standards that help customers achieve superior manufacturing results.

-

Aluminum alloy rust resistance and surface protection represent critical engineering considerations in modern industrial applications, where natural oxide films require enhancement through advanced anodizing processes to ensure long-term durability and performance. While aluminum alloys naturally generate protective oxide films when exposed to air, these naturally occurring layers may corrode over time in harsh environmental conditions, necessitating artificial anodizing treatments that create thicker, more robust protective films with enhanced surface hardness and corrosion resistance. WKPT specializes in hard anodizing processes for applications such as 6061T6 aluminum alloy casings used in medical testing equipment, employing precisely controlled temperature, voltage, and current density parameters to achieve 25µm thick protective layers with HV500 hardness that meet ISO10074 standards. This advanced surface treatment technology extends across multiple industries including aviation, aerospace, automotive, electronics, optics, and construction, providing lightweight, high-strength, acid-alkali-resistant components with superior wear resistance, enhanced conductivity, improved optical performance, and extended service life in extreme operating environments.

-

WKPT’s automatic production line consists of an Italian COMAU NS series six-axis robotic arm, which can grip 16 kg materials, and the repeatability accuracy reaches 0.05mm. Also with COMAU Rebel four-axis robotic arm can grip 6 kg materials and the repeatability accuracy reaches 0.02mm.

-

In the field of precision machining, there are many factors that can affect the yield of finished products; human factors are one of them. How to reduce the impact of human factors on yield is the focus of what we’ve improved in the past. In recent years, we have imported the online measurement system and established an automatic production line, which has successfully reduced the impact of human factors on the yield of finished products.

-

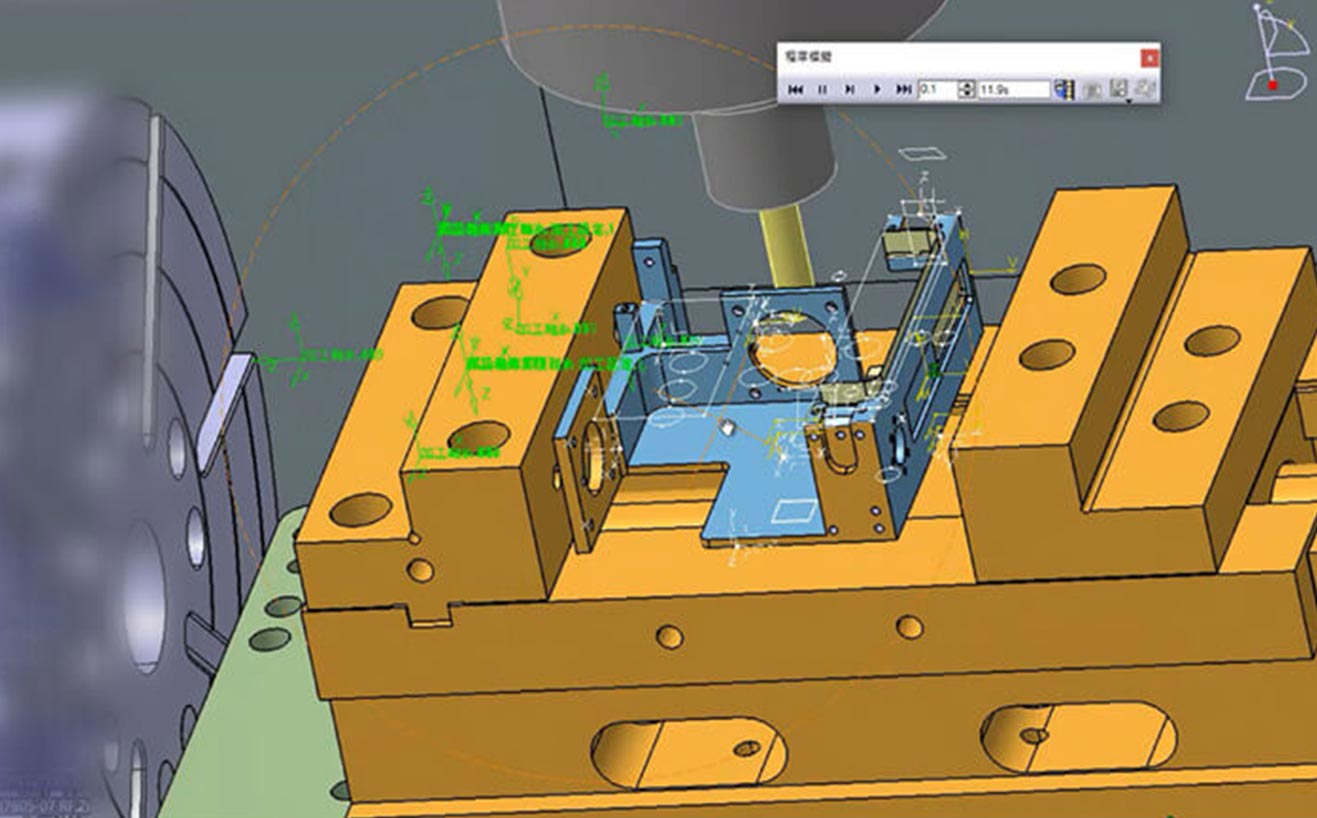

CATIA was developed in the 1980s by French software design company Dassault Systèmes S.A. It was originally used for aircraft manufacturing and later expanded to other product design applications, including automobile, vessel, and other consumer goods. With technology developing, the application of CATIA has been spread to the aviation, national defense, transportation, high technology, industrial equipment, construction, and biomedical industries.

-

One of our precision metalworking solutions is assembly and welding. Welding is the technique of joining metals or other materials by means of heat or pressure. Modern welding technology first appeared at the end of the 19th century and has developed various welding methods, such as gas welding, arc welding, laser beam welding, etc. Among the metal materials that we commonly use, cast iron is known for its high elongation, and stainless steel is high temperature and corrosion resistant, which is a commonly used metal material under the modern energy-saving trend. Various metals have their own properties, and it is expected to have a hybrid positive effect on the application of products.