Knowledge Base

-

WKPT discovered abnormal tool vibration during a machining process and immediately initiated a root cause analysis. The team employed the 4M1E method to comprehensively investigate the causes of the problem. This serves as one of many root cause analysis examples in the manufacturing sector. Based on the investigation results, the company designed and implemented a complete solution:

-

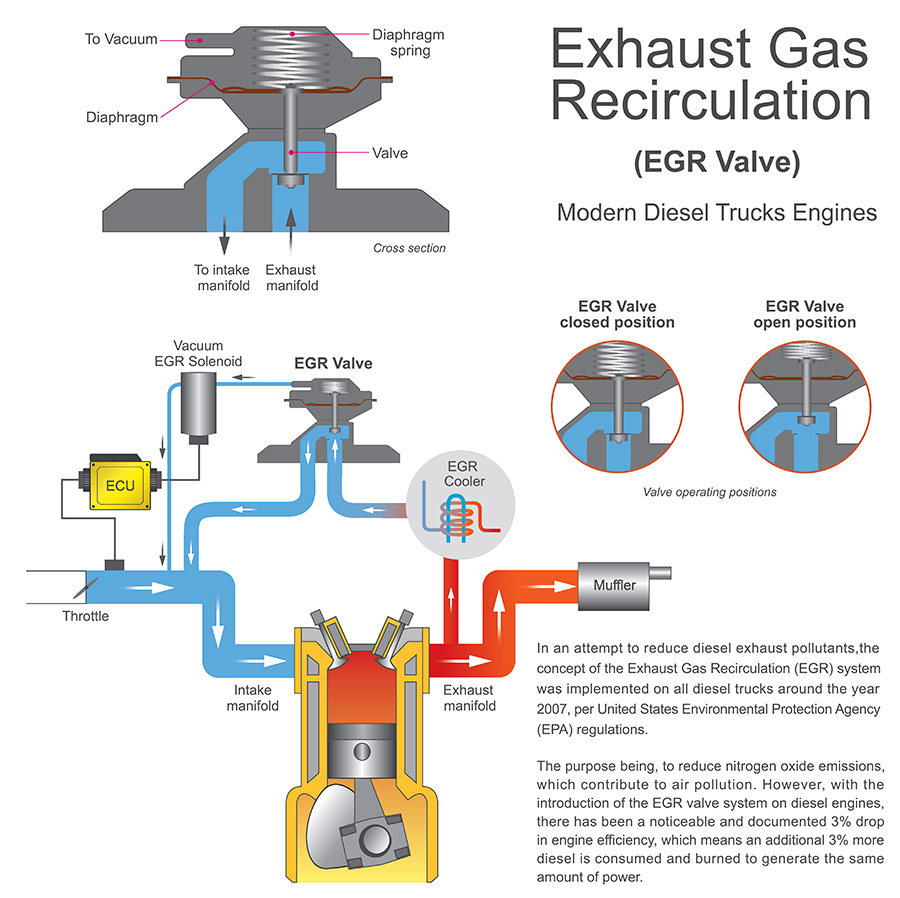

What is EGR? How does EGR contribute to environmental protection? Introduction to common EGR materials, quality standards, and development trends.

-

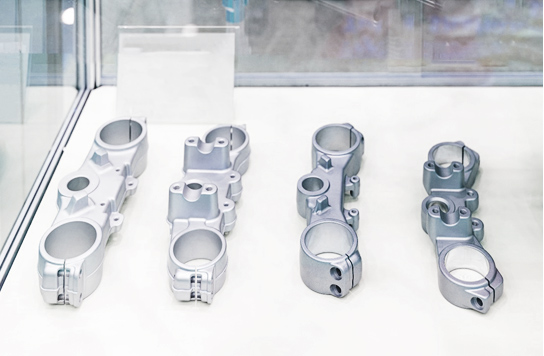

The casting industry predominantly manufactures cast iron parts, with non-ferrous metals comprising a minority share. Casting products find applications across various sectors, including transportation, agricultural machinery, construction engineering, renewable energy, and medical engineering. In the automotive and aviation industries, heightened environmental awareness has spurred the development of lightweight products to minimize energy consumption, prompting advancements in casting technology. This article provides a brief overview of the evolving development trends in casting technology in response to market demands.

-

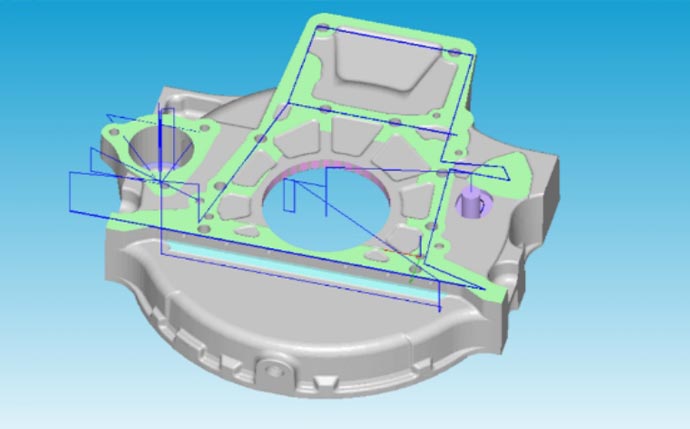

Process optimization represents a cutting-edge approach to sustainable manufacturing, utilizing advanced cutting force mechanics simulations and smart manufacturing technologies to minimize environmental impact. WKPT's innovative "Production Process Upgrade with Smart Manufacturing for Automotive Component" project employs sophisticated algorithms to analyze chip thickness, cutting force, spindle load, and tool load at each point along machining tool paths. Through precise feed rate adjustments and 3D simulation software, this technology optimizes machining programs to reduce unnecessary power consumption, protect equipment, and significantly lower carbon emissions while maintaining superior product quality and precision.

-

Wind energy component manufacturing represents a critical sector in global carbon neutrality efforts following the 2015 United Nations Climate Change Conference (COP 21) commitment to achieve zero emissions by 2050, driving economic growth and industrial transformation through renewable energy development. WKPT serves as Taiwan's exclusive supplier of wind turbine brake cylinders, providing comprehensive manufacturing solutions for wind power motor gearboxes, yaw brake systems, emergency brake systems, hydraulic systems, and brake components to Tier-1 supply chains and original equipment manufacturers. Our advanced engineering capabilities address the transition from onshore to offshore wind power applications, developing specialized low-temperature resistance ductile iron materials superior to EN-GJS-LT standards that maintain exceptional impact toughness in -20℃ environments, with ongoing development for -40℃ to -60℃ conditions. For offshore wind turbines operating in hypersaline and underwater environments including splash zones, intertidal zones, and underwater zones, WKPT's protective coating systems meet ISO 12944 C3M/C4H industry standards, ensuring 15-year durability against corrosion while maintaining ISO 9001 and IATF 16949 quality management through collaborative design and precision manufacturing solutions.

-

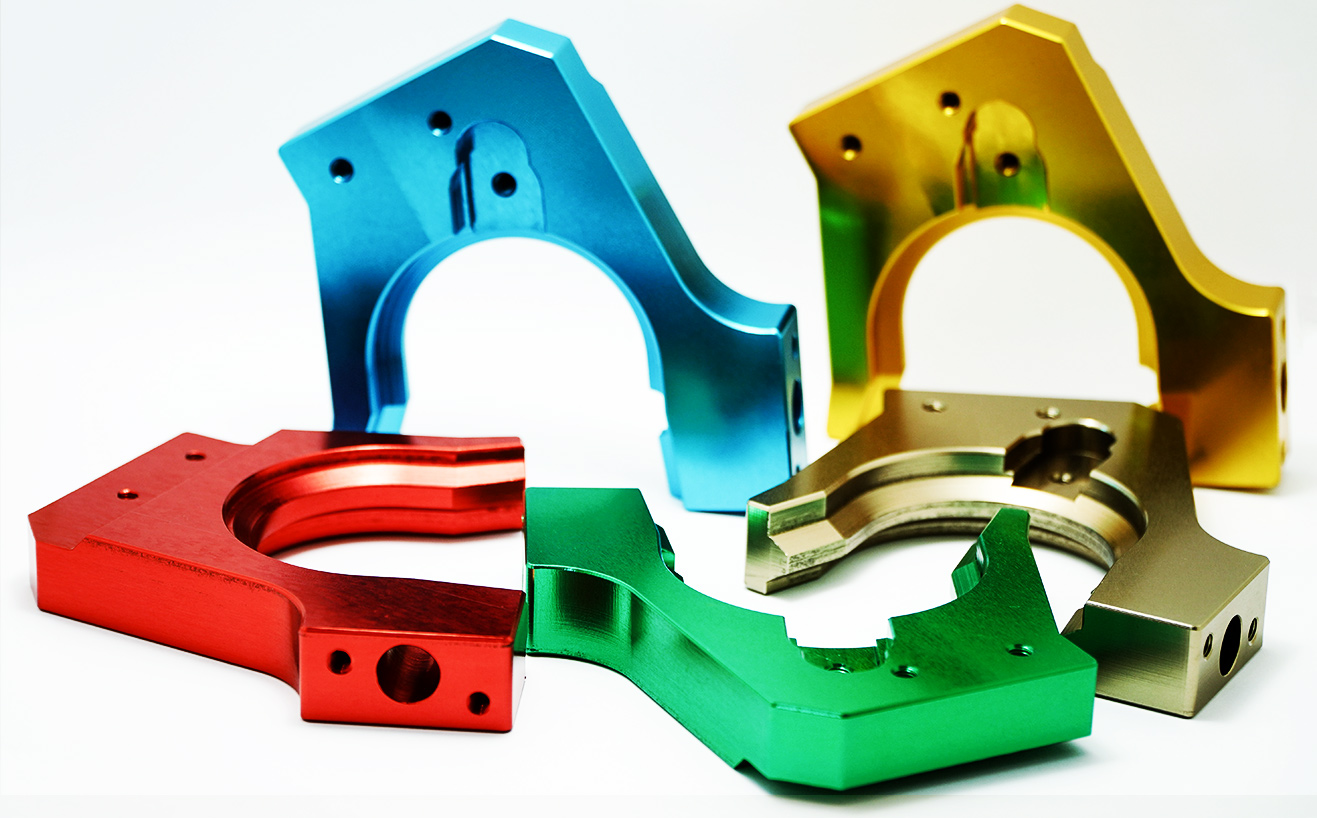

WKPT provides surface treatment services such as liquid coating, powder coating, electroplating, etc. on machined parts such as aluminum alloy, cast iron, stainless steel, and carbon steel. The surface treatment of aluminum alloy parts is mainly anodizing and hard anodizing.

-

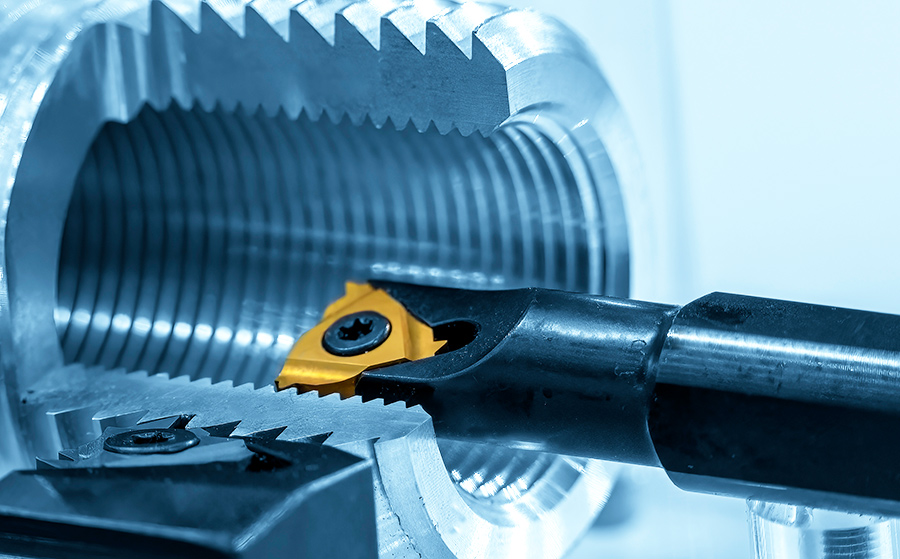

Thread machining services: thread turning, thread milling, and thread tapping. Thread turning involves cutting with shaping tools or thread tools on a rotating workpiece, suitable for precision manufacturing of internal and external threads in small quantities.

-

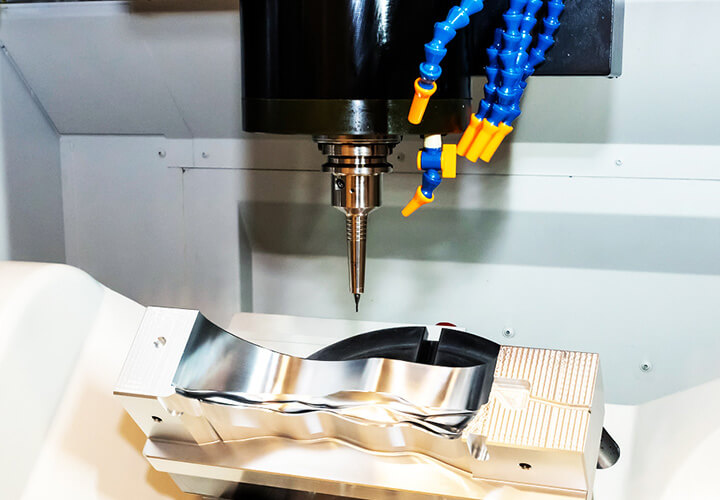

Discover WKPT's 5-axis CNC machining services for complex, high-precision parts. We specialize in multi-angle machining, customized production, and automated efficiency for demanding industries.

-

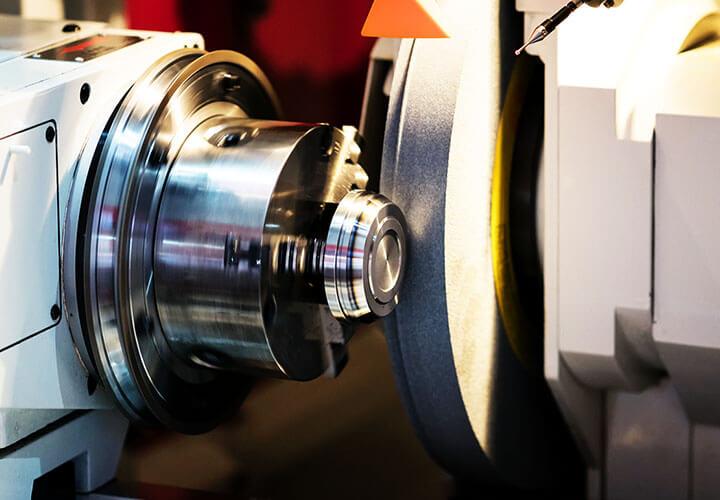

The precision quality of industrial products continuously improving, and the requirements of precision of parts manufacturing are also higher than before, which has reached the demand of micrometers (㎛).